Garmin GT15M-TH User manual

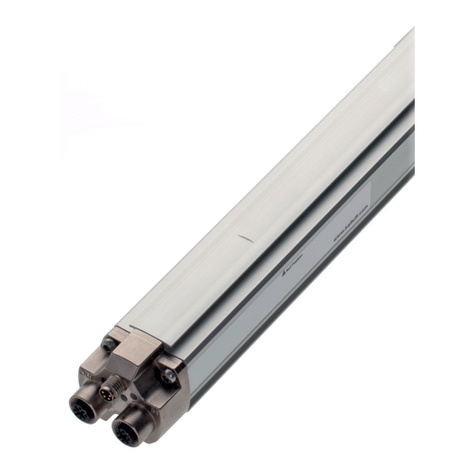

GT15M-TH Transducer

Installation Instructions

Important Safety Information

WARNING

See the Important Safety and Product Information guide in the

chartplotter or fishfinder product box for product warnings and

other important information.

The device must be installed with at least one of the included

anti-rotation bolts. Failure to do so could result in the device

rotating while the boat is moving and could cause damage to

your vessel.

You are responsible for the safe and prudent operation of your

vessel. Sonar is a tool that enhances your awareness of the

water beneath your boat. It does not relieve you of the

responsibility of observing the water around your boat as you

navigate.

CAUTION

Failure to install and maintain this equipment in accordance with

these instructions could result in damage or injury.

Always wear safety goggles, ear protection, and a dust mask

when drilling, cutting, or sanding.

NOTICE

When drilling or cutting, always check what is on the opposite

side of the surface.

To obtain the best performance and to avoid damage to your

boat, you must install the Garmin® device according to these

instructions.

Read all installation instructions before proceeding with the

installation. If you experience difficulty during the installation,

contact Garmin Product Support.

Registering Your Device

Help us better support you by completing our online registration

today.

• Go to my.garmin.com/registration.

• Keep the original sales receipt, or a photocopy, in a safe

place.

Software Update

You may need to update the device software when you install

the device or add an accessory to the device.

This device supports up to a 32 GB memory card, formatted to

FAT32.

Loading the New Software on a Memory Card

You must copy the software update to a memory card using a

computer that is running Windows® software.

NOTE: You can contact Garmin customer support to order a

preloaded software update card if you do not have a computer

with Windows software.

1Insert a memory card into the card slot on the computer.

2Go to garmin.com/support/software/marine.html.

3Select Download next to the software bundle that

corresponds with your chartplotter.

NOTE: The software download includes updates for all

devices connected to the chartplotter. Select the correct

bundle that corresponds to the chartplotter to be updated.

You can select See All Devices in this Bundle to confirm the

devices included in your download.

4Read and agree to the terms.

5Select Download.

6If necessary, select Run.

7If necessary, select the drive associated with the memory

card, and select Next > Finish.

8Extract the files to the memory card.

NOTE: The software update can take several minutes to load

onto the memory card.

Updating the Device Software

Before you can update the software, you must obtain a

software-update memory card or load the latest software onto a

memory card.

1Turn on the chartplotter.

2After the home screen appears, insert the memory card into

the card slot.

NOTE: In order for the software update instructions to

appear, the device must be fully booted before the card is

inserted.

3Follow the on-screen instructions.

4Wait several minutes while the software update process

completes.

5When prompted, leave the memory card in place and restart

the chartplotter manually.

6Remove the memory card.

NOTE: If the memory card is removed before the device

restarts fully, the software update is not complete.

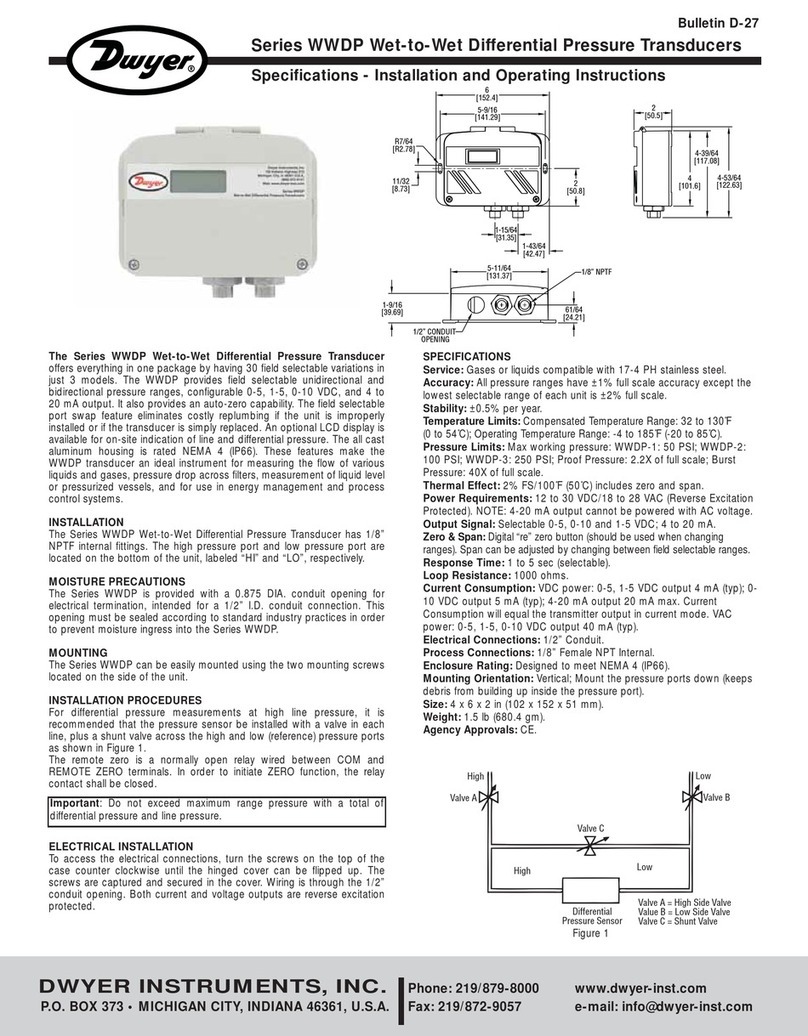

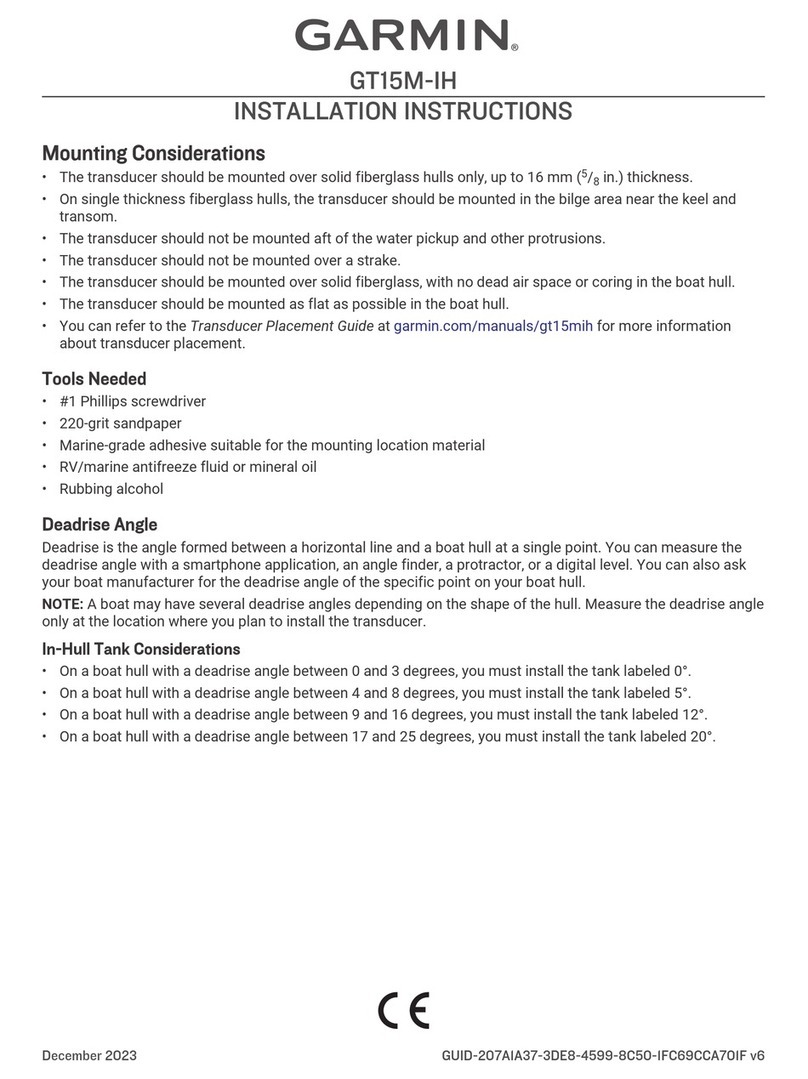

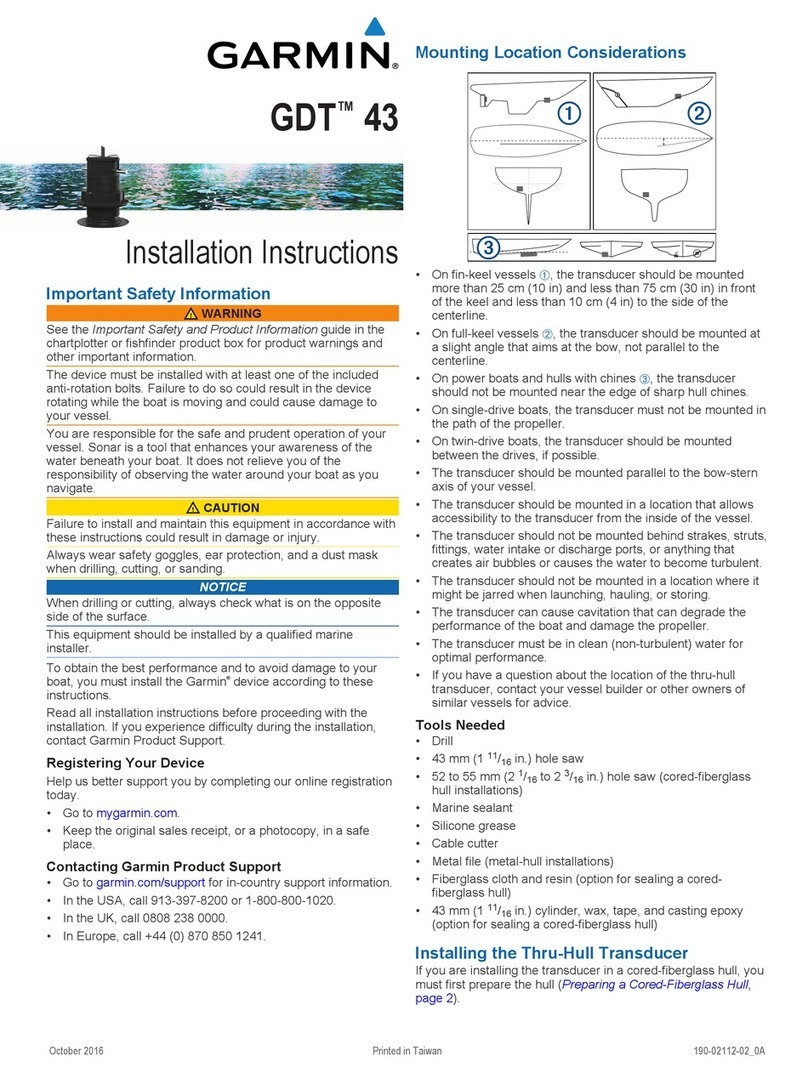

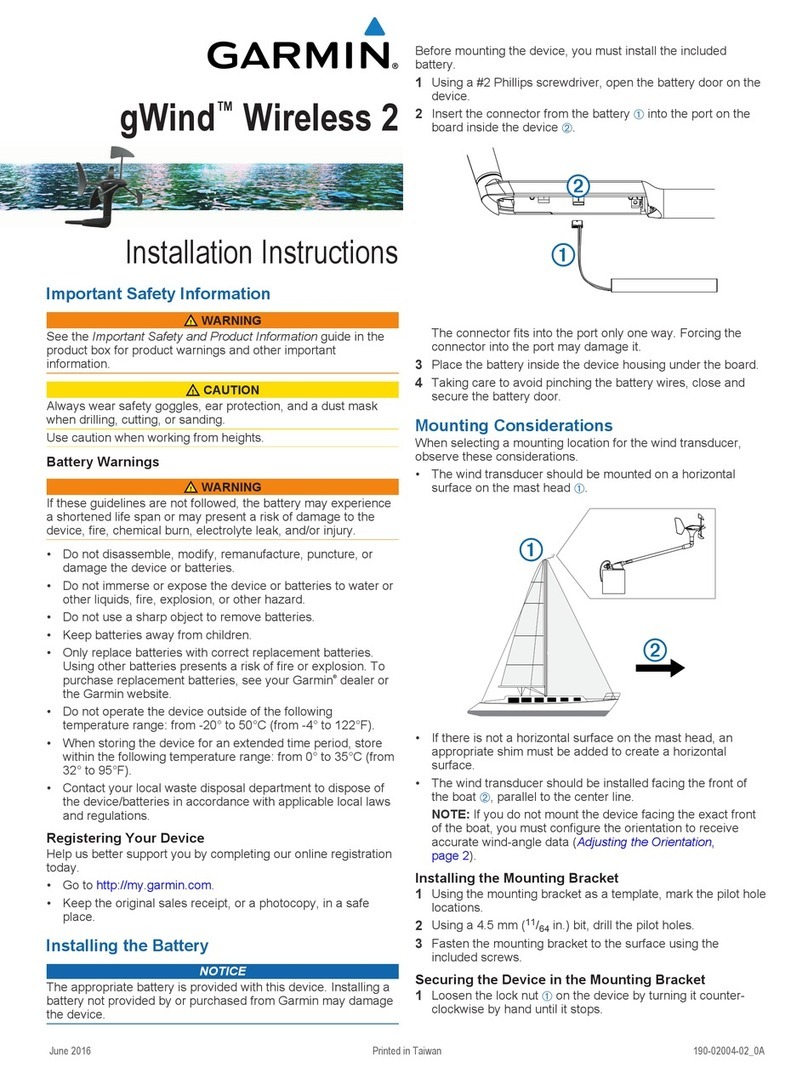

Mounting Considerations

• On a boat with more than a 5° deadrise angle, a fairing block

will need to be fabricated (not available for sale).

• On a boat with a 12° deadrise angle, the transducer with a

fairing block can accommodate a hull up to 29 mm (1.15 in.)

thick.

• On a boat with a 20° deadrise angle, the transducer with a

fairing block can accommodate a hull up to 19 mm (3/4 in.)

thick.

• On displacement hull vessels, the transducer should be

mounted near the centerline.

• On planing hull vessels, the transducer should be mounted

aft, on or near the centerline, inboard of the first set of lifting

strakes.

• On displacement hull and planing hull vessels, the transducer

should be mounted on the starboard side of the hull where

the propeller blades are moving downward.

• On stepped hull vessels, the transducer should be mounted

directly in front of the first step.

April 2017

190-02161-02_0B

• On fin-keel vessels, the transducer should be mounted more

than 300 mm (12 in.) and less than 600 mm (24 in.) in front of

the keel and on or near the centerline.

• On full-keel vessels, the transducer should be mounted in the

center of the ship, away from the keel at the point of

minimum deadrise.

• On single-drive vessels, the transducer must not be mounted

in the path of the propeller.

• On twin-drive vessels, the transducer should be mounted

between the drives, if possible.

• The transducer must be mounted on a flat location at less

than 6° of deadrise angle.

• The transducer should be mounted well ahead of the

propellers and shafts.

• The transducer should be mounted in a location where it is

vertical when the boat is underway. If the transducer leans

forward, the marine bottom can appear to slope upward. If

the transducer leans aft, some surface clutter may appear.

• The transducer should be mounted more than 600 mm

(24 in.) from other transducers.

• The transducer should be mounted in a location that is

unobstructed by the keel or propeller shafts.

• The transducer must be mounted in a location where it is

continuously immersed in water.

• The transducer should be mounted in a location that allows

accessibility to the transducer from the inside of the vessel.

• The transducer should not be mounted behind strakes, struts,

fittings, water intake or discharge ports, or anything that

creates air bubbles or causes the water to become turbulent.

• The transducer should not be mounted in a location where it

might be jarred when launching, hauling, or storing.

• The transducer can cause cavitation that can degrade the

performance of the boat and damage the propeller.

• The transducer must be in clean (non-turbulent) water for

optimal performance.

• If you have a question about the location of the thru-hull

transducer, contact your vessel builder or other owners of

similar vessels for advice.

Tools Needed

• Drill and 3 mm (1/8 in.) bit

• 25 mm (1 in.) hole saw (fiberglass hull)

• 32 mm (1 1/4 in.) hole saw (metal hulls)

• Sandpaper

• Masking tape

• Marine sealant

• Slip-joint pliers (metal hulls)

• Metal file (metal hulls)

• Epoxy or exposed core sealant (cored fiberglass hulls)

• Fiberglass cloth and resin (option for sealing a cored-

fiberglass hull)

• Cable ties

Cored Fiberglass Boat Hull Installation

Instructions

Drilling a Hole in a Cored-Fiberglass Hull

1From inside the boat, drill a 3 mm (1/8 in.) pilot hole

completely through the hull.

2Examine the pilot hole on the outside of the boat, and select

an option:

• If the pilot hole is not in the correct location, seal the hole

with epoxy and repeat step 1.

• If the pilot hole is in the correct location, use a 25 mm (1

in.) hole saw to cut a hole from the outside of the boat

through the outer fiberglass skin only. Do not cut

completely through the hull.

3On the inside of the boat, at the pilot hole location, use a hole

saw to cut a hole 9 to 12 mm (3/8 to 1/2 in.) larger than the

hole you cut in the outside of the boat in step 2.

Cut through the inner fiberglass skin and most of the core,

without cutting the outer skin.

NOTE: When cutting the inner fiberglass skin and core, be

careful to not cut the outer fiberglass skin, or you will not be

able to correctly seal the hull.

4Remove the inner fiberglass skin and core you cut in step 3.

You should be able to see the inside of the outer fiberglass

skin.

5Sand the inside of the hole and the areas immediately around

both the inside and outside fiberglass skin.

6Clean the area using a mild detergent or weak solvent, such

as isopropyl alcohol, to remove any dust and dirt.

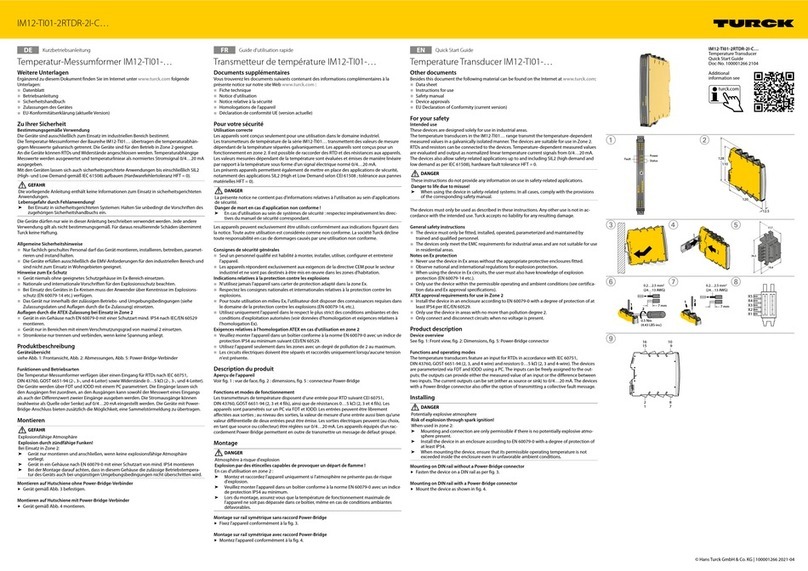

Preparing a Cored-Fiberglass Hull

NOTICE

If the core of a cored-fiberglass hull is not sealed properly, water

may seep into the core and severely damage the boat.

ÀFiberglass or casting epoxy (not included)

ÁCylinder spacer (included bushing)

ÂInner fiberglass skin

ÃCore

ÄOuter fiberglass skin

1Drill the hole through the hull.

2Seal the core inside the hull using either fiberglass (Sealing

the Core with Fiberglass, page 3) or casting epoxy

(Sealing the Core with Casting Epoxy, page 3).

2

Sealing the Core with Fiberglass

1From inside the boat, coat a layer of fiberglass cloth with

fiberglass resin and place it inside the hole to seal the core.

2Add layers of fiberglass cloth and resin until the hole is

25 mm (1 in.) in diameter.

3After the fiberglass has hardened, sand and clean inside and

around the hole.

The cored-fiberglass hull is now prepared, and you can

complete the transducer installation.

Sealing the Core with Casting Epoxy

1Coat the included 25 mm (1 in.) cylinder with wax.

2From outside the boat, insert the cylinder into the hole, and

tape it in place on the outer surface.

3Fill the space between the cylinder and the core with casting

epoxy.

4After the epoxy has hardened, remove the cylinder, sand and

clean inside and around the hole.

The cored-fiberglass hull is prepared, and you can complete

the transducer installation.

Applying Marine Sealant to a Thru-hull Transducer

You must apply marine sealant to the water path to ensure a

tight, waterproof seal between the transducer and hull.

Apply a 2 mm (1/16 in.) layer of marine sealant to the flange of

the housing that will contact the hull, and up the sidewall of

the housing.

NOTE: The sealant must extend 6 mm (1/4 in.) above the top

of the hull to seal the hull and secure the hull nut.

Installing the Transducer in a Fiberglass Hull

It is recommended that two installers complete these

instructions, with one positioned outside the boat and one inside

the boat.

NOTE: When installing a transducer in a fiberglass hull, avoid

over-tightening the nuts to prevent damaging the hull.

1From outside the hull, insert the transducer À through the

mounting hole, using a twisting motion to squeeze out excess

sealant.

2From inside the hull Á, slide the rubber washer Â, nylon

washer Ã, and hull nut Ä onto the stem.

3Use slip-joint pliers or a crescent wrench to hold the stem,

and secure the hull nut to the transducer stem.

Do not over-tighten the hull nut.

4Before the sealant hardens, remove all excess sealant on the

outside of the exterior hull to ensure smooth water flow over

the transducer.

Non-cored/Fiberglass/Wooden Boat Hull

Installation Instructions

Drilling a Hole in a Non-Cored Hull

1Select a mounting location (Mounting Considerations,

page 1).

2Drill a 3 mm (1/8 in.) pilot hole from outside the hull.

3If the vessel has a fiberglass hull, place masking tape over

the pilot hole and surrounding area outside the hull to prevent

damage to the fiberglass.

4If you taped over the pilot hole, use a utility knife to cut out

the hole in the tape.

5While holding a 25 mm (1 in.) spade bit plumb, cut a hole

from outside the hull at the stem hole location.

6Sand and clean the area around the hole.

Applying Marine Sealant to a Thru-hull Transducer

You must apply marine sealant to the water path to ensure a

tight, waterproof seal between the transducer and hull.

Apply a 2 mm (1/16 in.) layer of marine sealant to the flange of

the housing that will contact the hull, and up the sidewall of

the housing.

NOTE: The sealant must extend 6 mm (1/4 in.) above the top

of the hull to seal the hull and secure the hull nut.

Installing the Transducer in a Fiberglass Hull

It is recommended that two installers complete these

instructions, with one positioned outside the boat and one inside

the boat.

NOTE: When installing a transducer in a fiberglass hull, avoid

over-tightening the nuts to prevent damaging the hull.

1From outside the hull, insert the transducer À through the

mounting hole, using a twisting motion to squeeze out excess

sealant.

2From inside the hull Á, slide the rubber washer Â, nylon

washer Ã, and hull nut Ä onto the stem.

3Use slip-joint pliers or a crescent wrench to hold the stem,

and secure the hull nut to the transducer stem.

Do not over-tighten the hull nut.

4Before the sealant hardens, remove all excess sealant on the

outside of the exterior hull to ensure smooth water flow over

the transducer.

Metal Boat Hull Installation Instructions

Drilling a Hole in a Metal Hull

1Select a mounting location (Mounting Considerations,

page 1).

2From outside the hull, drill a 3 mm (1/8 in.) pilot hole through

the hull.

The hole must be perpendicular to the water surface.

3Using a 32 mm (1 1/4 in.) hole saw, cut the stem hole from

outside the hull.

4Sand and clean the area around the holes.

Applying Marine Sealant to a Thru-hull Transducer in

a Metal Hull

You must apply marine sealant to the water path to ensure a

tight, waterproof seal between the transducer and hull.

1Apply a 2 mm (1/16 in.) layer of marine sealant to the flange of

the housing that will contact the hull, and up the sidewall of

the housing.

3

NOTE: The sealant must extend 6 mm (1/4 in.) above the top

of the hull to seal the hull and secure the hull nut.

2Slide the isolation plate and bushing onto the stem, and apply

sealant to the surfaces of the plate and bushing that will

contact the hull. Fill the cavities in and around the plate and

bushing.

Installing the Transducer in a Metal Hull

It is recommended that two installers complete these

instructions, with one positioned outside the boat and one inside

the boat.

1From outside the hull, insert the transducer À through the

isolation plate Á and bushing Â.

2Insert the transducer with plate and bushing through the

mounting hole, using a twisting motion to squeeze out excess

sealant.

3If necessary, trim the bushing.

NOTE: The bushing must be below the hull nut when

installed.

4From inside the hull Ã, slide the rubber washer Ä, nylon

washer Å, and hull nut Æ onto the stem.

5Use slip-joint pliers or a crescent wrench to hold the stem,

and secure the hull nut to the transducer stem.

Do not over-tighten the hull nut.

6Before the sealant hardens, remove all excess sealant on the

outside of the exterior hull to ensure smooth water flow over

the transducer.

Maintenance

Testing the Installation

NOTICE

You should check your boat for leaks before you leave it in the

water for an extended period of time.

Because water is necessary to carry the sonar signal, the

transducer must be in the water to work properly. You cannot

get a depth or distance reading when out of the water. When

you place your boat in the water, check for leaks around any

screw holes that were added below the water line.

Anti-Fouling Paint

To prevent corrosion on metal hulls and to slow the growth of

organisms that can affect a vessel's performance and durability,

you should apply a water-based anti-fouling paint to the hull of

your vessel every six months.

NOTE: Never apply ketone-based anti-fouling paint to your

vessel, because ketones attack many types of plastic and could

damage or destroy your transducer.

Cleaning the Transducer

Aquatic fouling accumulates quickly and can reduce your

device's performance.

1Remove the fouling with a soft cloth and mild detergent.

2If the fouling is severe, use a scouring pad or putty knife to

remove growth.

3Wipe the device dry.

Specifications

Specification Measurement

Frequencies* From 80 to 160 kHz

Maximum depth** 549 m (1800 ft.)

Transmit power 600 W

Operating temperature range From 0° to 50°C (from 32° to 122°F)

Storage temperature range From -40° to 70°C (from -40° to 158°F)

*Dependent upon the chartplotter or fishfinder model.

**Dependent upon water conditions.

© 2017 Garmin Ltd. or its subsidiaries

Garmin® and the Garmin logo are trademarks of Garmin Ltd. or its subsidiaries,

registered in the USA and other countries. Panoptix™ is a trademark of Garmin Ltd. or its

subsidiaries. These trademarks may not be used without the express permission of

Garmin.

Table of contents

Other Garmin Transducer manuals

Garmin

Garmin GT8HW-TM User manual

Garmin

Garmin GT30-TM User manual

Garmin

Garmin GT15M-IH User manual

Garmin

Garmin GDT 43 User manual

Garmin

Garmin Panoptix PS21-TR User manual

Garmin

Garmin GT51 Thru-Hull User manual

Garmin

Garmin gWind Race User manual

Garmin

Garmin gWind Wireless 2 User manual

Garmin

Garmin GT12M-THF User manual

Garmin

Garmin LIVESCOPE PLUS User manual