4

0704EN February 2020

Metering systeMs

Heat Interface UnIt wItH electronIc regUlatIon

ge556Y401, ge556Y402

ge556-2 serIes

047U53918

Settings of the remote control/chronothermostat

Operation in mode: OFF, SUMMER, WINTER, HEATING ONLY

The selection of the operating mode is done by repeatedly pressing the

button .

O: “OFF”and the current time are shown on the display. Only the antifreeze

function (if set) is enabled in this mode. Any request for the DHW or heating

mode operation is ignored.

Summer: the measured room temperature, the current time and the icon are

displayed . The DHW, if set, and the antifreeze function are enabled in this

mode. Any request for the heating mode operation is ignored.

Winter: the display shows the measured room temperature, the time and the

current day, the icons and the program set for the current day. All DHW,

heating and, if set, antifreeze functions are enabled in this mode.

Heating only: the display shows the measured room temperature, the time

and the current day, the icon and the program set for the current day. All

heating and, if set, antifreeze functions are enabled in this mode. Any request

for the DHW mode operation is ignored.

Clock and temperature setting

Depending on the operating mode selected (OFF / SUMMER / WINTER

/ HEATING ONLY) by pressing the button , the clock and the

temperature of the boiler can be set.

The value is displayed for a time equal to the display settings time delay and

is identied by its ashing icon. Press key to pass to the next value

and turn the knob to modify the value.

Clock: press key until the icon and the time value start to ash .

Turn the knob to select the desired time.

Press the knob to pass to the minutes.

The minutes start ashing: turn the knob to select the desired

minutes. Press the knob to pass to the day of the week. The days of

the week start ashing: turn the knob to select the desired day. Press

the knob to conrm the value entered.

Day Set point: press key until the icon and the day set point

value start to ash .

Turn the knob to select the desired value.

Night Set point: press key until the icon and the night set

point value start to ash .

Turn the knob to select the desired value.

Heating Set point: press key until the icon and the heating set

point value start to ash .

Turn the knob to select the desired value.

DHW Set point: press key until the icon and the DHW set

point value start to ash .

Turn the knob to select the desired value.

Kd: this setting is only available if the remote control is congured as

the modulator with the use of the external probe (P04 = 2 or 3). press key

until the icon and the relative value start to ash. Turn the knob

to select the desired value.

NB:

For the other operating modes of the remote control, refer to the

corresponding instruction sheet.

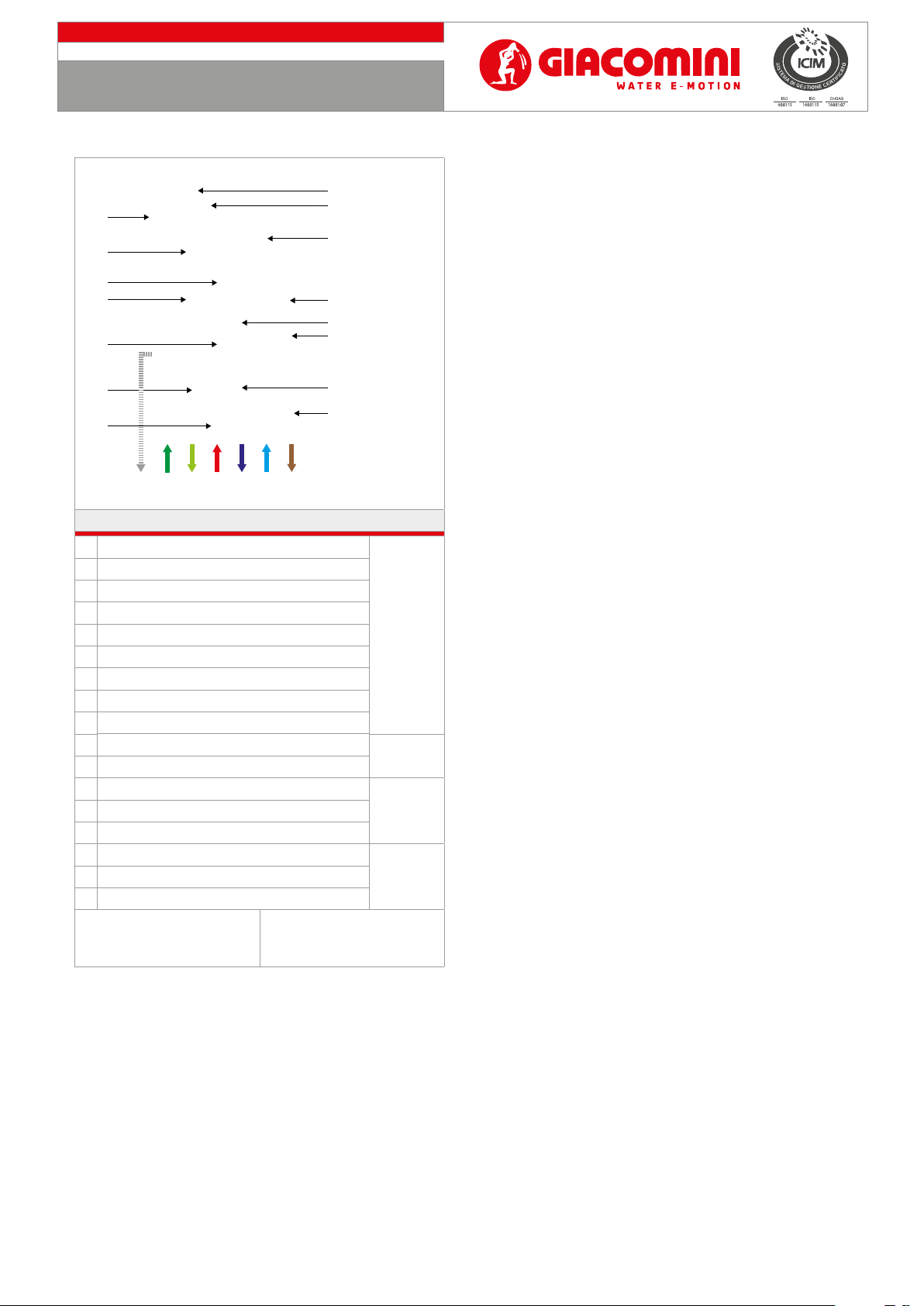

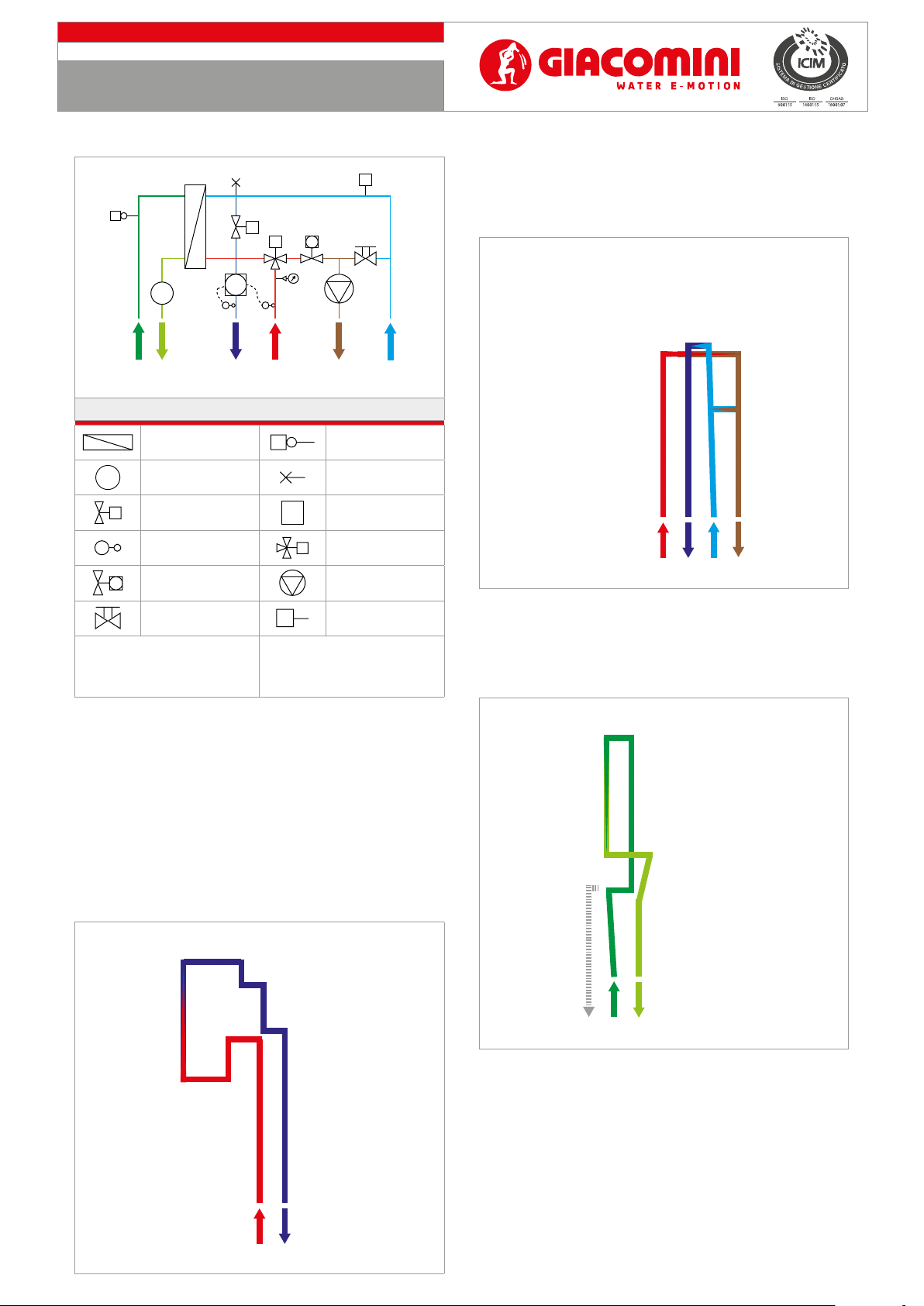

Electric connections

Electronic board

An electrical cabinet IP55 containing the electronic control board is located

at the top right of the HIU.

• The HIU is powered electrically by connecting the 230 V mains supply to the

three-pin terminal board M1 of the electronic board.

•The remote control /chronothermostat (K480Y002) is connected to terminals

23-24 of the electronic board.

• The external temperature probe (K365PY002) is connected to terminals 27-

28 of the electronic board.

• The optional safety thermostat (K373/K373I), is connected to terminals 39-40

of the electronic board.

• Multizone additional control to terminals 21-22 on the electronic board

(additional thermostats to be ordered separately).

24 23 22 21 20 1932 31 30 29 28 27 26 2540 39 38 37 36 35 34 3342 41

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

L N

M1

18

17

16

SAFETY

THERMOSTAT

K373 / K373I

REMOTE COMMAND /

CHRONOTHERMOSTAT

K480Y002

CONTROL FOR

MULTIZONE

EXTERNAL

TEMPERATURE

PROBE K365P

230 VAC

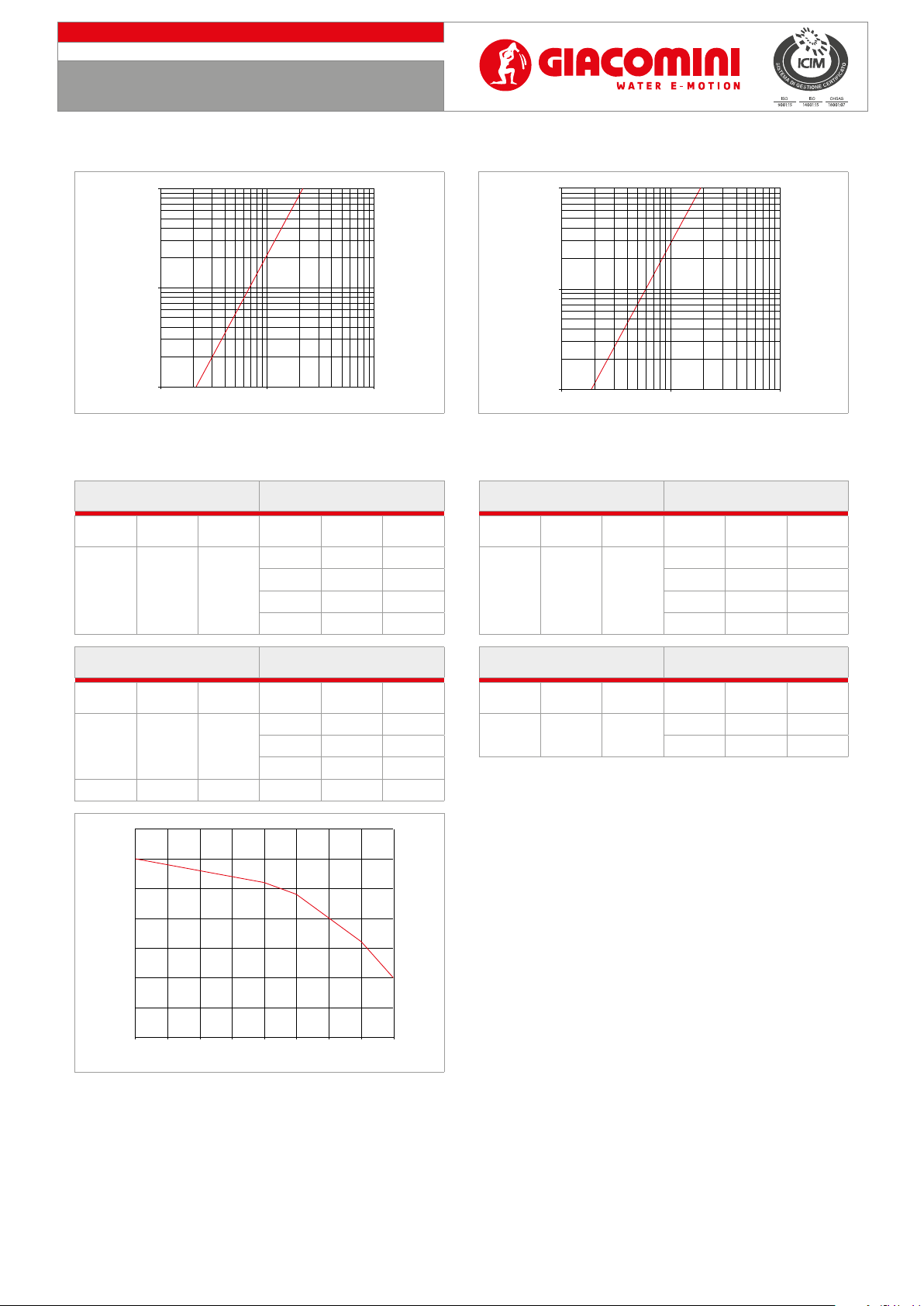

Technical data

• Electronic board power supply of the HIU: 230 V

• Supply voltage frequency: 50÷60 Hz

• Ambient operating temperature: -20÷60 °C

• Ambient storage temperature: -20÷80 °C

• Humidity: max 90 % @ 40° C non-condensing

• Maximum absorption: 7 VA

• Maximum length of external probe cable: 30 m

• Maximum length of remote control cable: 30 m

M-Bus

To connect the M-Bus data transfer cable to the concentrator, refer to the data

sheet of the heat energy meter used.

Protection and safety systems

Warning. Risk of burns and electric shock. The HIU must only

be accessed by skilled personnel, authorised by the building

administrator.

It is important that the HIU are accessed only by skilled personnel authorised

by the building administrator: the box is locked. As optional is possible to

install a K373/K373I safaty thermostat to prevent the high temperature on

the heating side.

Checks and Maintenance

Warning. Installation must be carried out by skilled personnel, authorised

by the building administrator. Respect the regulations regarding the use

(installation, xing, etc.), operation, recalibration and replacement of the

meters. Refer also to the assembly instructions provided with the meter.

Warning. Before connecting the template to the HIU, remove the lock

nuts from the threaded connections.

Heating circuit pressure

Regularly check the pressure in the heating circuit by means of the

manometer: the pressure value must be kept above 1 bar (values lower than

this may cause cavitation, damaging the circulator). There is a pressure switch

with a 0,8 bar setting to protect the circulator.

Warning. The HIU will turn o and the display on the remote control

signals an error E71 if the pressure is less than 0,8 bar.

Fill the system again to restart the HIU.

You must set up a lling system for heating - i.e. a connection from the

domestic circuit to the heating circuit, with a suitable backow preventer.

Attention: risk of burns. Use the manual air vent to remove the air in the circuit.