Electronaut M97 User manual

M97 COMPRESSOR/LIMITER

USER’s GUIDE

Serial Number Built By Build Date Ship Date Line Voltage set to

120 240

ELECTRONAUT COMPANY

Revision 0, January 2016

USER’S GUIDE 2

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

SERIOUSLY.

Read this entire manual before plugging in and turning on the M97!

Refer servicing to qualified personnel only!

To prevent electric shock, do not operate the M97 near water or moisture!

USER’S GUIDE 3

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

TABLE OF

CONTENTS

CONTACT

INFORMATION 5

DECLARATION of CONFORMITY 5

THANK YOU SINCERELY 6

GETTING STARTED 8

INSPECTION 8

OPENING THE CRATE 8

REMOVING THE M97 FROM

THE CRATE 8

THOROUGH INSPECTION

PROCEDURE 9

CONFIGURATION 9

FRONT PANEL 9

REAR PANEL 9

B+ ADJUST (325V) KNOB 10

BALANCE/CHASSIS KNOB 10

IEC POWER INLET SWITCH 10

INSTALLATION 11

AIRFLOW AND THERMAL

CONSIDERATIONS 11

CALIBRATION 11

POWER UP the M97 11

CALIBRATING THE B+ VOLTAGE 11

CALIBRATING THE BALANCE 12

THE BALANCING SYSTEM 12

BALANCE CALIBRATION

PROCEDURE 12

BALANCE/CHASSIS 14

AT THIS POINT THE M97

SHOULD BE PROPERLY CALIBRATED

AND READY FOR SERVICE

REFERENCE 15

INPUT ATTENUATOR 15

THE INPUT ATTENUATOR and the

HIGH FREQUENCY RESPONSE 17

THE CONTROLLING AMPLIFIER 18

DC THRESHOLD 18

ATTACK 18

RELEASE 19

ATTACK and RELEASE

INTERDEPENDENCE 19

THE USABILITY OF THE FASTEST

ATTACK TIMES 19

USER’S GUIDE 4

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

SUGGESTED SET-UP FOR

TRANSIENT LIMITING: 19

UNDERSTANDING THE EFFECTS

OF THE AC AND DC THRESHOLD

CONTROLS 20

COMPRESSION CURVES 21

A NOTE ABOUT WORKFLOW 22

CHOOSING A CURVE BY

MAXIMUM OUTPUT 22

THE METERING SYSTEM 25

METER MODE KNOB 25

THE SIGNAL GENERATOR 26

MAKING GOOD USE OF THE

TONE AND METER 26

SET FOR UNITY GAIN: 26

FIGURE OUT WHERE THE “KNEE”

(OR EFFECTIVE THRESHOLD) OF

THE COMPRESSION CURVE IS: 26

HIGH PASS FILTER 27

BYPASS/COMPRESS/PASS 27

BYPASS 27

COMPRESS 27

PASS 27

The FUNCTION SWITCH 28

NORMAL 28

SIDECHAIN 28

INTERLOCK 28

SIDECHAIN/INTERLOCK 28

EXTERNAL 28

LINKING TWO M97S FOR STEREO 29

BLOCK DIAGRAM OF SIGNAL AND

CONTROL CIRCUITRY 30

POWER SCHEME 31

METER MODE SWITCH 31

IEC POWER INLET 31

IEC POWER CABLE 31

REPLACING THE FUSES 32

MAIN FUSES 32

INTERNAL FUSES 32

REPLACEMENT FUSE PART

NUMBERS 33

TUBE COMPLEMENT 33

OPTIONAL REMOTE-CUTOFF

TUBES 35

TUBE SOCKET WIRING AND TUBE

COMPATIBILITY 36

HEATER VOLTAGE TOGGLE

SWITCH 36

REPLACING THE TUBES 36

WARRANTY & REGISTRATION 37

SERVICING 37

SPECIFICATIONS 38

ACKNOWLEDGEMENTS 39

REIN NARMA 39

DR. DANIEL FLICKINGER 39

MIKE AND KAY DORROUGH 39

EARLY BELIEVERS 39

TABLE OF FIGURES 40

TABLE OF TABLES 41

USER’S GUIDE 5

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

CONTACT

INFORMATION

Electronaut Company

333 N Oakley Blvd STE 100

Chicago, IL 60612 U.S.A.

(312) 212-3983 (skype)

All information provided in this manual is

thought to be accurate and free of errors at

the time of printing; however, Electronaut

Company shall not be held liable for any errors

or omissions in this manual, nor any

subsequent damage resulting from the use of

the information in this manual. This manual

and any future updates can be downloaded

from the Electronaut Company website, at:

www.electronaut.info/manuals

This user’s manual contains information

protected by copyright. No part of this manual

may be reproduced in any form without prior

written consent from Electronaut Company.

©2002–2016 Electronaut Company

M97_UsersManual.pdf

DECLARATION of

CONFORMITY

Name of Manufacturer:

Electronaut Company

Address of Maufacturer:

333 N. Oakley Blvd. Ste 100

Chicago, IL 60612

USA

Product:

M97 Compressor/Limiter

Declaration:

ELECTRONAUT COMPANY is committed to

manufacturing products that are

fully-compliant with the RoHS Directive.

The M97 Compressor/Limiter complies with

the requirements of the Low Voltage Directive

(73/23/EEC) and the protection requirements

of the EMC Directive (89/336/EEC) issued by

the Commission of the European Community.

The M97 Compressor/Limiter is built

with RoHS-compliant components and is

assembled with RoHS-compliant lead-free

solder and assembly processes.

USER’S GUIDE 6

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

First of all,

THANK YOU

SINCERELY

for adding the M97 Compressor/Limiter to

your system. This compressor is the result of

literally thousands of hours of eort studying,

experimenting, designing, building, testing,

listening, redesigning, rebuilding, retesting,

relistening, (insert seemingly ininite loop

here), until a compressor finally emerged

that seemed refined enough to be worthy

of production. The sheer amount of work

required to undertake such a project begs the

question: does the world really need another

monster tube variable-mu1compressor?

Aren’t there already enough Fairchild clones

available?

The answers are unequivocally YES, and YES.

The year 2016 marks 110 years since the triode

vacuum tube was invented in Chicago in 1906.

As we look back over this incredible span of

ingenuity, a trend-line immediately reveals a

constant incremental progress, with creative

thinkers picking up where others left oand

pushing things a little bit further, inspired by

limitations they thought could be improved

upon. Every single audio equipment designer

throughout history benefited from the work

done by their predecessors, and the trend

of incremental progress happened because

people were driven to look forward and think

of new ideas. The engineers that created the

tools we musicians and recordists depend

upon generally shared three key things: a

willingness to study and learn from the past,

a solid understanding of the present, and a

creative vision for the future.

Something interesting started to happen

within the last couple of decades: musicians

and engineers began to realize that despite

a century of constant progress, many old

designs still held their own against new

designs, and in a lot of instances the older

designs simply sounded better. One hundred

years of constant improvement had also been

heavily influenced by 100 years of economic

interests, and the result wasn’t always good

for the sound. This realization, combined with

the emergence of internet auction services

and a globally interconnected world, inspired a

frenzy of trading in vintage electronics, which

in turn inspired a frenzy of manufacturers

issuing ‘clones’ of vintage designs.

Deeply rooted in Electronaut’s philosophy is

a belief that audio equipment design should

be informed not only by an engineering

perspective, but also from a musician’s

perspective. If we consider equipment design

from a musician’s perspective, some things

immediately become clear: cloning other

people’s designs from the past is basically

the same thing as being in a cover band.

Cloning is an attempt to celebrate the work

of people who left behind a legacy that still

may have untapped market potential, just as

a classic-rock cover band may find paid work

playing other people’s songs at weddings

or corporate events. There’s nothing wrong

with that, and there are many examples of

designers who have labored tirelessly to

reproduce every detail of a vintage design to

exacting standards, flaws and all, just as there

are musicians who have labored tirelessly to

perfect every riin the Beatles’ discography.

A lot of people really want to hear songs from

the past performed live, so naturally someone

will step up and provide such an experience.

That’s just how the world works.

But the world works in other ways too: people

are creative and not everyone is interested in

mimicking other people’s original ideas. Many

people have their own ideas and a strong

desire to actualize them, and that’s the reason

we have new music and art and books and

movies.

For some people, admiration for the great

work of the past reaches a fever pitch,

resulting in a belief that these past works are

so perfect that they can never be improved

upon. Again, viewed from the musician’s

perspective, this seems totally absurd: try

convincing musicians that they shouldn’t

bother to write new music because great

music has already been achieved!

The world needs another variable-mu

compressor because the variable-mu

technique is an amazing idea with a totally

unique sound that has stood the test of time,

and continues to show new potential even in

a vastly dierent technological world. Simply

USER’S GUIDE 7

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

stated, the idea still works amazingly well, yet

there is still plenty of room for improvement.

But does the M97 sound like a Fairchild or not?

The M97 is a heavy-duty, single-stage variable-

mu compression amplifier with a fast and

powerful controlling amplifier, and as such it

shares many of the qualities that made the

Fairchilds sound the way they do. However,

no attempt has been made to mimic the

Fairchild’s limitations. Instead, Electronaut

designed a series of improvements that

just make sense in a 21st century vari-mu,

including: continuously-variable attack and

release controls instead of a small number

of fixed time constants, a higher-current

controlling amplifier providing faster attack

and improved peak transient reduction

capability, a significantly-improved balance

calibration method for reduced distortion and

thump-free operation, Lundahl transformers

for improved frequency response and optimal

interfacing, a 24-position balanced bridged-T

input attenuator, a tube regulated high voltage

power supply filtered solely by a large choke

and four polypropylene capacitors, and a

vastly superior dB-accurate metering system

displaying input and output level, threshold

level, gain reduction, 2nd harmonic distortion,

and even peak transient reduction!

Ultimately, the important characteristic is the

audio circuit topology: the Fairchild was a

single-stage variable-mu compressor with a

powerful controlling amplifier, and at the time

it was arguably the best implementation of

that particular technique. What made it such a

great sounding compressor was not that it had

a magic combination of flaws; what made it

great was that it expanded the usability of the

variable-mu concept to the extent that it could

handle nearly any type of program material —

something previous variable-mu compressors,

arguably, could not achieve.

One of the main advantages of the single-

stage approach is an incredibly simple signal

path: an input transformer, a tube amplifier,

and an output transformer. Not even a single

capacitor is present in the signal path.

Not all variable-mu compressors are built

this way — many currently available designs

economize on the vari-mu stage and add

additional capacitively-coupled gain stages

to make up for it, but this is a move in the

direction of a more complex signal path, which

in Electronaut’s belief, is fine when necessary

but less than ideal.

Simpler is almost always better, and the

single-stage variable-mu concept managed to

maintain a simple signal path while oering

ample control of the audio’s dynamics.

Electronaut chose to use this approach as its

jumping opoint, and to try and hunt down

things that could be improved upon, not only

in terms of sonics, but in usability, interface,

and features.

In Electronaut’s view, the prevailing spirit of

pro audio equipment design is the desire to

constantly improve, just as a musician may

practice for a lifetime to constantly improve.

An environment where recordists exhibit

a healthy resistance to stagnation and the

status quo is better for every musician who

ever wants to make a record. We can let

the luddites be luddites without criticism or

judgement, and remember that they don’t

have to stand in the way of new ideas.

With this spirit in mind, Electronaut humbly

presents the M97 Compressor/Limiter. I

couldn’t be happier with the results, and I

can’t wait for you to hear it!

Rob Roy M. Campbell

January, 2016

USER’S GUIDE 8

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

GETTING STARTED

Preparing the M97 for service requires the

following five steps to be carried out in order:

1) Inspection

2) Configuration

3) Installation

4) Calibration

5) Reference

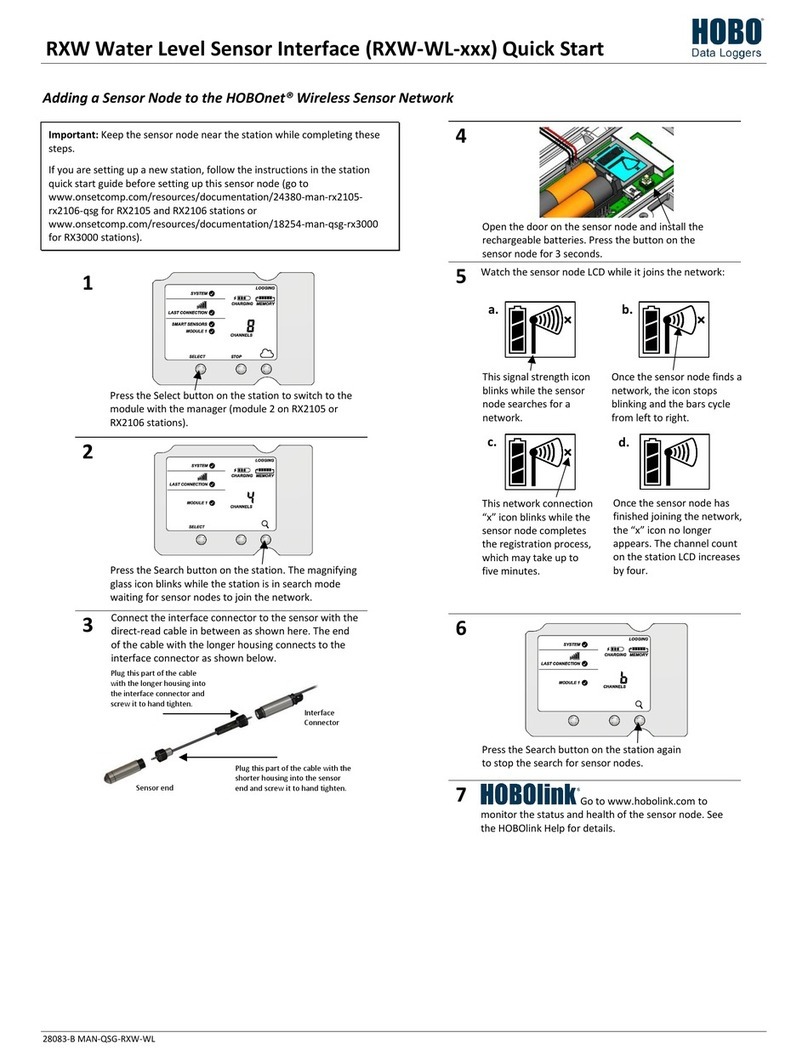

INSPECTION

The M97 Compressor/Limiter is shipped in a

wooden crate with a pouch for the shipping

label that includes a Shockwatch™ drop

indicator. If the crate has been dropped or has

otherwise suered a shock exceeding 75G, the

drop indicator will change to red. See Figure 1.

Figure 1 — The little plastic vile in the center of the

Shockwatch™ label will turn RED if the crate has

suered excess shock during transit.

In the event that a crate has been received

with a red drop indicator, please notify the

carrier immediately, and follow the “Thorough

Inspection Procedure” on page 9, before

applying power to the M97.

OPENING THE CRATE

The top cover of the crate is attached by 10

small metal tabs. Locate the tabs and use

pliars or a screwdriver to bend each tab

vertically. Once all 10 tabs are vertical, lift the

cover othe crate and set it aside.

See Figure 2.

CAUTION:

The metal edges are sharp!

The M97 weighs 33 lbs (15kg).

Figure 2 — Pry up the tabs on the wooden

crate and liothe top cover.

REMOVING THE M97 FROM

THE CRATE

The M97 is suspended within the crate by two

foam side caps. See Figure 3.

Lift the M97 and foam caps from the crate and

set it on a sturdy table surface. Remove the

foam endcaps and plastic wrapping. Set aside

the documentation and power cord, and place

the packaging materials back in the crate for

storage.

Figure 3 — The M97 is insulated from shock and

suspended in place by two foam end-caps.

USER’S GUIDE 9

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

THOROUGH INSPECTION

PROCEDURE

It’s a good idea to thoroughly inspect the M97,

especially if the shipping container shows

evidence of exceedingly rough transport as

described above. The following procedure

should be performed before the power cable

is attached, preferably by an experienced

technician who is familiar with high voltage

vacuum tube equipment.

1. Look for signs of damage around the

external surfaces of the M97. Test every

switch and knob on the front and rear

panels for mechanical integrity.

2. Using a #2 Phillips screwdriver, remove all

of the top cover screws and set the cover

aside.

4. Inspect all tubes. Make sure they are

properly seated in their sockets, and make

sure that none of the tubes show a white

powdery substance inside the glass, which

would indicate a compromised vacuum.

Inspect for cracked glass and other signs of

damage. Contact Electronaut immediately

if any tubes appear to be damaged, and do

not apply power.

5. Take a minute to visually inspect the rest of

the internal electronics.

6. If everything appears to be okay, reinstall

the top cover. Install all eight screws loosely

by hand first; then, once they are all

installed, tighten all the screws.

If the inspection process causes any doubt

as to the condition of the M97 upon arrival,

please contact Electronaut immediately to

discuss it before proceding with the remainder

of the set-up process.

CONFIGURATION

Prior to installing the M97 into the equipment

rack, make the following settings to the front

and rear panel components.

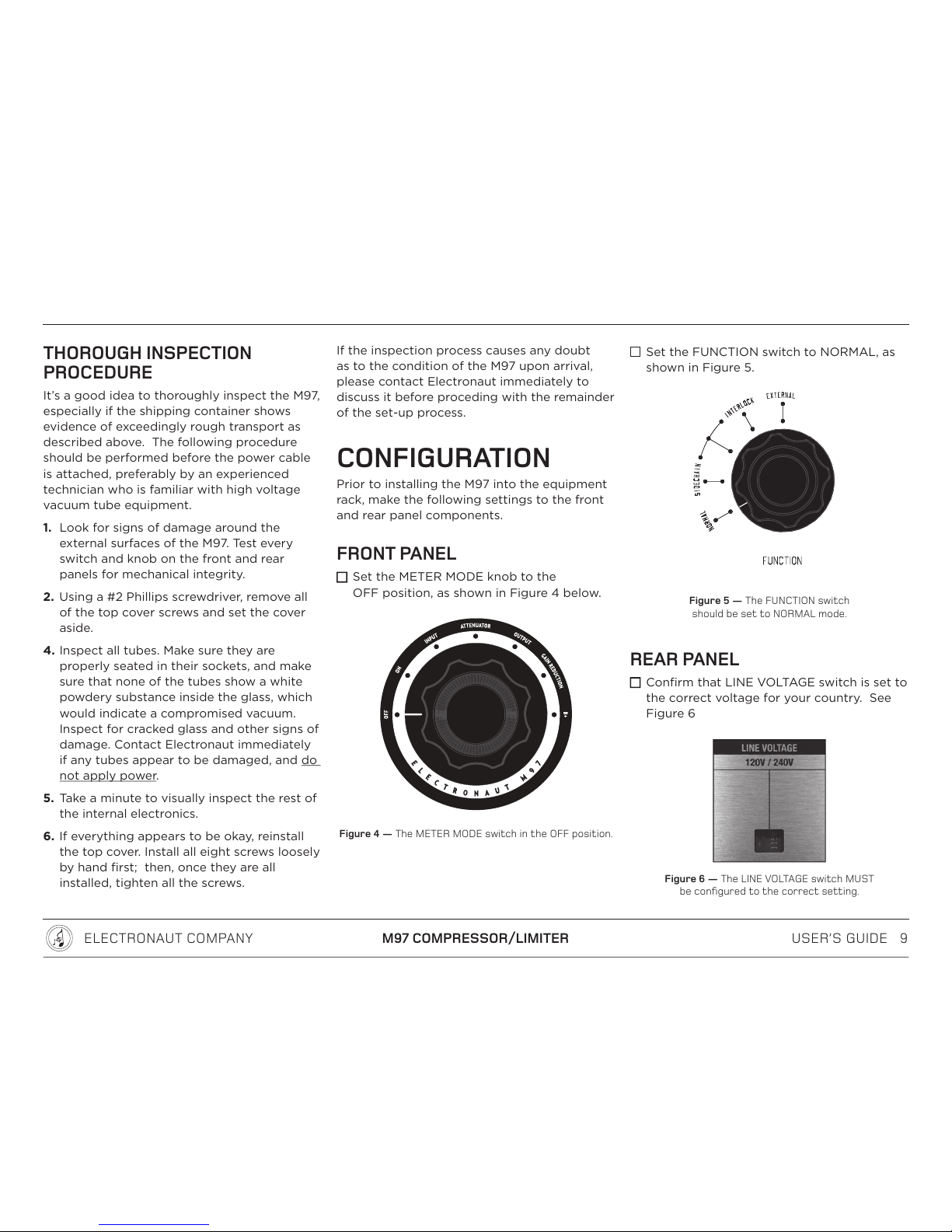

FRONT PANEL

Set the METER MODE knob to the

OFF position, as shown in Figure 4 below.

Figure 4 — The METER MODE switch in the OFF position.

Set the FUNCTION switch to NORMAL, as

shown in Figure 5.

Figure 5 — The FUNCTION switch

should be set to NORMAL mode.

REAR PANEL

Confirm that LINE VOLTAGE switch is set to

the correct voltage for your country. See

Figure 6

Figure 6 — The LINE VOLTAGE switch MUST

be configured to the correct setting.

USER’S GUIDE 10

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

NOTE:

The LINE VOLTAGE switch is old-school and

specifies the voltages as 115 or 230; however,

the intended operating voltages are 120 or

240 volts respectively.

To change the line voltage setting, use a flat

screwdriver to slide the switch to the correct

setting.

The LINE VOLTAGE switch is set at the factory

based on the buyer’s shipping address or by

request at the time of order.

The standard M97 accommodates 120 volt 60

Hz operation, as well as 240V 50 Hz operation.

Electronaut may be able to accommodate

other power line voltages and frequencies

upon request.

NOTE:

Do not operate the M97 with the

LINE VOLTAGE switch in the wrong position!

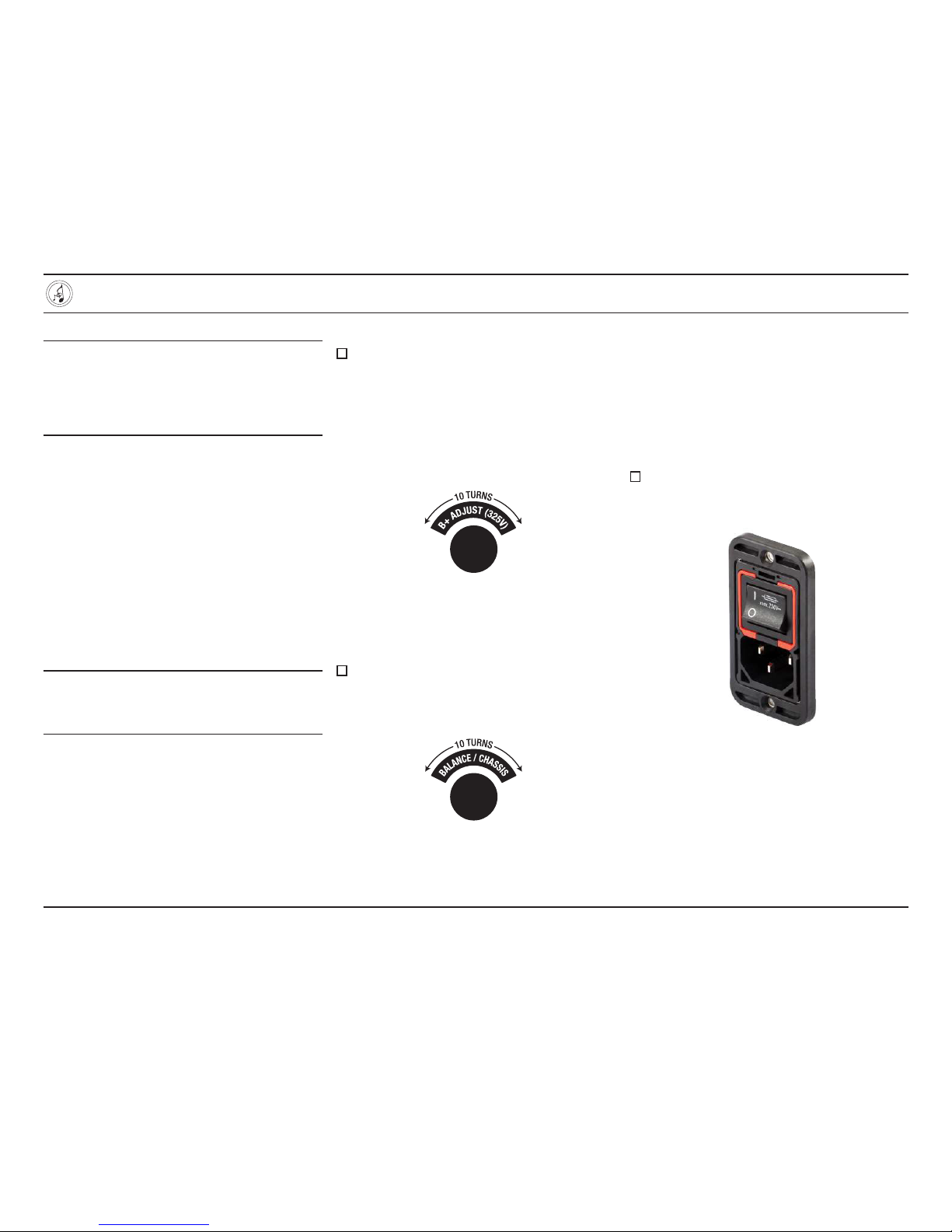

B+ ADJUST (325V) KNOB

Set the B+ ADJUST (325V) knob to its

center position. This is a 10-turn knob;

to find the center, turn the knob in one

direction continuously until it stops, then

turn it back five full rotations. (You can

count the rotation of the brass set-screw on

the top of the knob). See figure Figure 7.

Figure 7 — The B+ ADJUST control permits

adjustment of the high voltage tube regulator.

BALANCE/CHASSIS KNOB

Set the BALANCE/CHASSIS knob to its

center position. This is also a 10-turn knob;

refer to the procedure in the previous step.

Figure 8 — The BALANCE/CHASSIS control is a

secondary balancing control used to fine-tune

the balance the push-pull audio amplifier.

IEC POWER INLET SWITCH

The IEC power inlet includes a switch which

is used to completely disconnect the mains

power from the M97. See ““POWER SCHEME”

on page 29.

The ON position is shown by the symbol “I”,

and the OFF position is shown by the symbol

“O”. See Figure 9 below.

Switch the IEC power switch to the OFF or

“O” position.

Figure 9 — The IEC power inlet, with the

switch shown in the ON position.

USER’S GUIDE 11

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

INSTALLATION

NOTE:

These instructions assume that you will have

access to the rear panel of the M97 after it

has been installed into your rack. If your

rack prohibits rear-panel access, perform the

CALIBRATION procedures before installation.

The M97 is designed to be mounted in a

standard 19” equipment rack, occupying four

units (4U) of rack space. Additional space

above and below is strongly recommended to

ensure adequate airflow around the unit.

A locking IEC power cable is included with

North American versions, but any IEC cable

with a current rating of 5A or higher will work

fine. (See ““IEC POWER CABLE” on page 29 for

stock part numbers).

AIRFLOW AND THERMAL CONSIDERATIONS

The M97 is designed to run fairly cool

considering the number of tubes and the size

of the power supply, but it is normal for the

unit to be warm to the touch. The M97 should

never be so hot as to make it impossible to

leave your hand on the side panels or the top

and bottom covers indefinitely.

Avoid installing the M97 into an equipment

rack shared by other excessively hot

equipment.

To help control the internal temperature, a

very quiet brushless-DC fan is installed on the

rear panel. The fan runs continuously when

the M97 is powered on.

NOTE:

The fan has a service life of 80,000 hours,

equivalent to 18 years of 12 hour-per-day

operation. It should be replaced near the end

of its service life.

Install the M97 into the equipment rack,

making sure to leave adequate space

around the unit for airflow.

Attach the power cable to the IEC power

inlet, and plug it into a power source.

CALIBRATION

For best performance, it is necessary to

calibrate the high voltage power supply as

well as the balance of the audio amplifier. This

calibration procedure should be followed at

the time of installation, then verified from time

to time as needed.

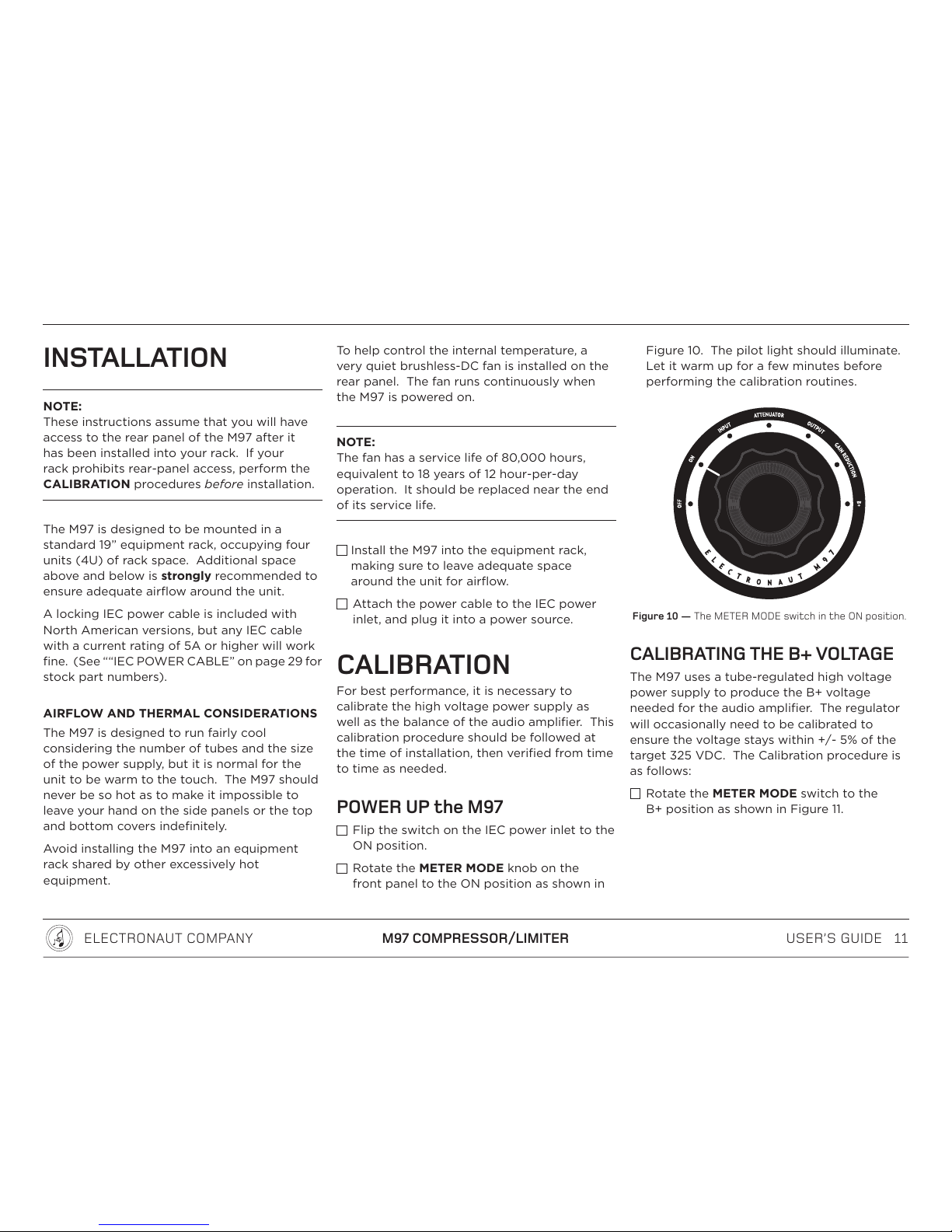

POWER UP the M97

Flip the switch on the IEC power inlet to the

ON position.

Rotate the METER MODE knob on the

front panel to the ON position as shown in

Figure 10. The pilot light should illuminate.

Let it warm up for a few minutes before

performing the calibration routines.

Figure 10 — The METER MODE switch in the ON position.

CALIBRATING THE B+ VOLTAGE

The M97 uses a tube-regulated high voltage

power supply to produce the B+ voltage

needed for the audio amplifier. The regulator

will occasionally need to be calibrated to

ensure the voltage stays within +/- 5% of the

target 325 VDC. The Calibration procedure is

as follows:

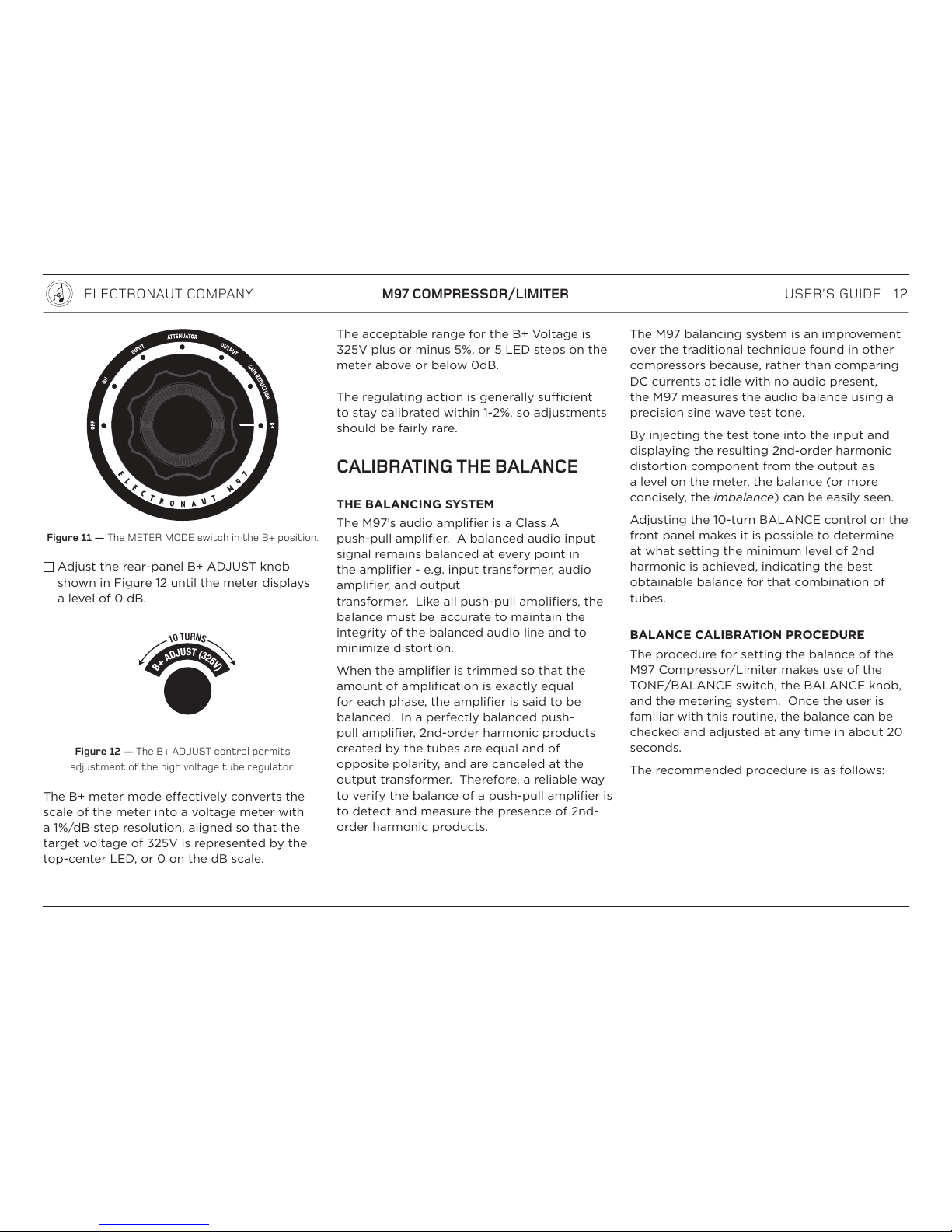

Rotate the METER MODE switch to the

B+ position as shown in Figure 11.

USER’S GUIDE 12

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

Figure 11 — The METER MODE switch in the B+ position.

Adjust the rear-panel B+ ADJUST knob

shown in Figure 12 until the meter displays

a level of 0 dB.

Figure 12 — The B+ ADJUST control permits

adjustment of the high voltage tube regulator.

The B+ meter mode eectively converts the

scale of the meter into a voltage meter with

a 1%/dB step resolution, aligned so that the

target voltage of 325V is represented by the

top-center LED, or 0 on the dB scale.

The acceptable range for the B+ Voltage is

325V plus or minus 5%, or 5 LED steps on the

meter above or below 0dB.

The regulating action is generally sucient

to stay calibrated within 1-2%, so adjustments

should be fairly rare.

CALIBRATING THE BALANCE

THE BALANCING SYSTEM

The M97’s audio amplifier is a Class A

push-pull amplifier. A balanced audio input

signal remains balanced at every point in

the amplifier - e.g. input transformer, audio

amplifier, and output

transformer. Like all push-pull amplifiers, the

balance must be accurate to maintain the

integrity of the balanced audio line and to

minimize distortion.

When the amplifier is trimmed so that the

amount of amplification is exactly equal

for each phase, the amplifier is said to be

balanced. In a perfectly balanced push-

pull amplifier, 2nd-order harmonic products

created by the tubes are equal and of

opposite polarity, and are canceled at the

output transformer. Therefore, a reliable way

to verify the balance of a push-pull amplifier is

to detect and measure the presence of 2nd-

order harmonic products.

The M97 balancing system is an improvement

over the traditional technique found in other

compressors because, rather than comparing

DC currents at idle with no audio present,

the M97 measures the audio balance using a

precision sine wave test tone.

By injecting the test tone into the input and

displaying the resulting 2nd-order harmonic

distortion component from the output as

a level on the meter, the balance (or more

concisely, the imbalance) can be easily seen.

Adjusting the 10-turn BALANCE control on the

front panel makes it is possible to determine

at what setting the minimum level of 2nd

harmonic is achieved, indicating the best

obtainable balance for that combination of

tubes.

BALANCE CALIBRATION PROCEDURE

The procedure for setting the balance of the

M97 Compressor/Limiter makes use of the

TONE/BALANCE switch, the BALANCE knob,

and the metering system. Once the user is

familiar with this routine, the balance can be

checked and adjusted at any time in about 20

seconds.

The recommended procedure is as follows:

USER’S GUIDE 13

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

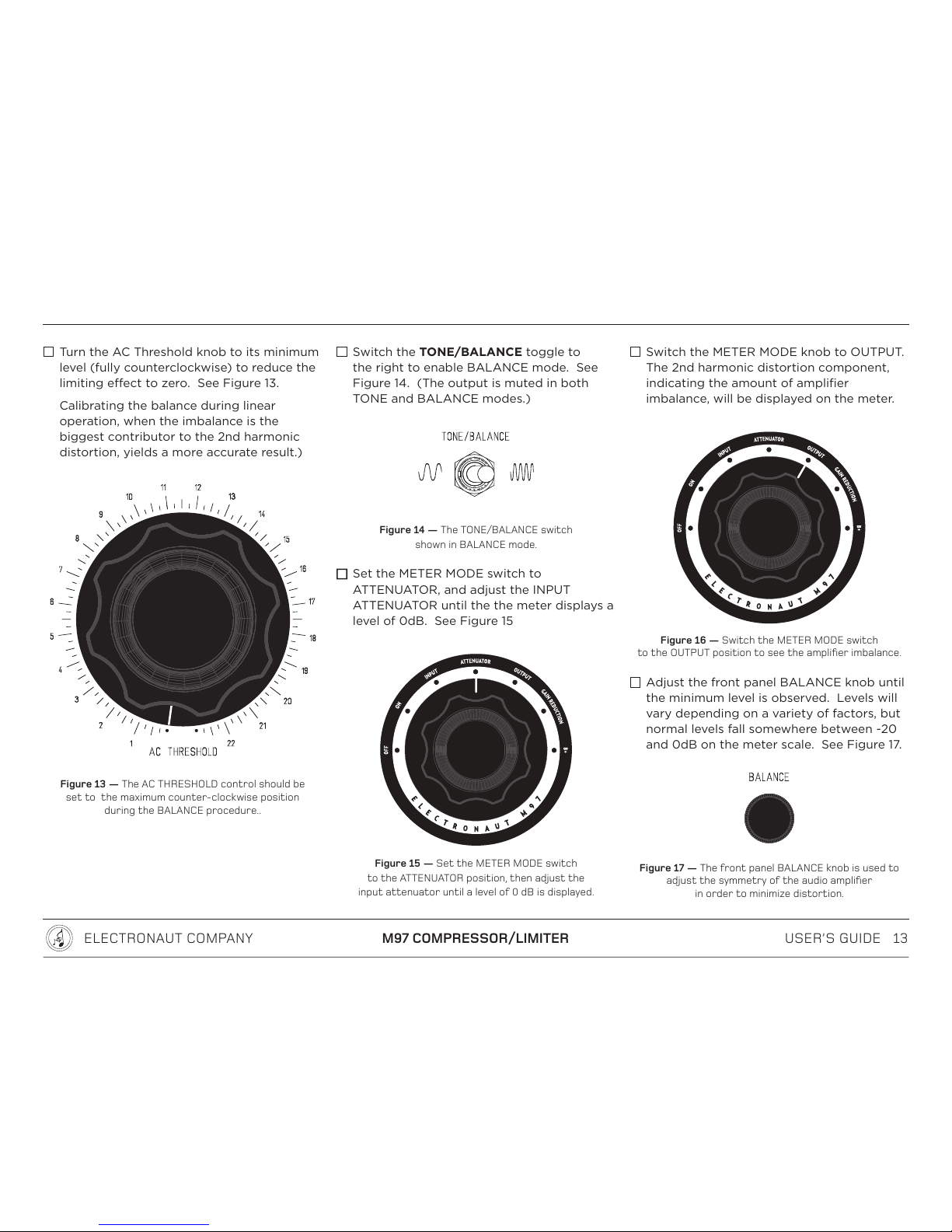

Turn the AC Threshold knob to its minimum

level (fully counterclockwise) to reduce the

limiting eect to zero. See Figure 13.

Calibrating the balance during linear

operation, when the imbalance is the

biggest contributor to the 2nd harmonic

distortion, yields a more accurate result.)

Figure 13 — The AC THRESHOLD control should be

set to the maximum counter-clockwise position

during the BALANCE procedure..

Switch the TONE/BALANCE toggle to

the right to enable BALANCE mode. See

Figure 14. (The output is muted in both

TONE and BALANCE modes.)

Figure 14 — The TONE/BALANCE switch

shown in BALANCE mode.

Set the METER MODE switch to

ATTENUATOR, and adjust the INPUT

ATTENUATOR until the the meter displays a

level of 0dB. See Figure 15

Figure 15 — Set the METER MODE switch

to the ATTENUATOR position, then adjust the

input attenuator until a level of 0 dB is displayed.

Switch the METER MODE knob to OUTPUT.

The 2nd harmonic distortion component,

indicating the amount of amplifier

imbalance, will be displayed on the meter.

Figure 16 — Switch the METER MODE switch

to the OUTPUT position to see the amplifier imbalance.

Adjust the front panel BALANCE knob until

the minimum level is observed. Levels will

vary depending on a variety of factors, but

normal levels fall somewhere between -20

and 0dB on the meter scale. See Figure 17.

Figure 17 — The front panel BALANCE knob is used to

adjust the symmetry of the audio amplifier

in order to minimize distortion.

USER’S GUIDE 14

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

Bear in mind that as the M97 approaches a

perfect balance, the 2nd harmonic is reduced

until it is eventually buried in the noise floor.

At this point the system cannot distinguish

between the 2nd harmonic and the noise, and

the level shown on the display gets “jumpy” as

it tries to track the subtle fluctuations of the

noise floor. This is about as perfect a balance

as is achievable without laboratory equipment.

With perfect tubes, the perfect balance would

be at the center of the BALANCE knob’s

rotational range, or 5 turns from either end-

stop. Real-world tubes will likely require some

other non-center setting.

NOTE:

The absolute value shown on the meter is not

important — it’s the relative value that matters!

The purpose of the calibration is to find the

minimum distortion obtainable for that set of

tubes.

The absolute level can vary by a few dB from

time to time, based on temperature and other

factors. This is normal and should not be of

concern.

It should be mentioned that a precise balance

is a theoretically correct target. For distortion

performance other than minimum, experiment

at will! One advantage of having a precise

balance control is the ease with which a

recalibration for minimum distortion can

be achieved after experimenting with other

settings.

BALANCE/CHASSIS

Most of the time, the BALANCE/CHASSIS

knob should be set to its center position, five

turns in from either end-stop. In rare cases

where mismatched tubes provide some

diculty in obtaining a good balance, the

BALANCE/CHASSIS knob can be employed

for further refinement if necessary.

See Figure 18.

Figure 18 — The BALANCE/CHASSIS control is a

secondary balancing control used to fine-tune

the balance the push-pull audio amplifier.

NOTE:

The engraving on the front panel of the M97

shows both the TONE and BALANCE symbols

as sine waves, but the BALANCE wave is at

twice the frequency. This symbolizes the

function of the BALANCE mode, which is to

detect and display the 2nd harmonic of the

test tone at the output of the audio amplifier.

AT THIS POINT THE M97

SHOULD BE PROPERLY CALIBRATED

AND READY FOR SERVICE

USER’S GUIDE 15

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

REFERENCE

To get the most out of the M97, it is

recommended that the remainder of this

manual be thoroughly read and understood.

INPUT ATTENUATOR

The input attenuator is a high-quality

24-position ELMA switch configured as

a balanced bridged-T network with an

impedance of 600 ohms. The attenuator

is placed between the input XLR and the

input transformer, and provides 1 dB steps

throughout its range, with an “o” mute

function at the most counterclockwise

position.

Once the AC and DC Thresholds and the

Attack and Release controls have been set up,

the degree of limiting can be controlled by

adjusting the input attenuator. See Figure 19.

Figure 19 — The INPUT ATTENUATOR is a 3-pole

23-position balanced bridged-T stepped attenuator.

USER’S GUIDE 16

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

when ZSOURCE = 100 ohms

Figure 20 — The high frequency response can be extended by setting the INPUT ATTENUATOR to zero

and driving the input with a lower impedance source signal, as shown here when driven by a 100 ohm signal.

USER’S GUIDE 17

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

THE INPUT ATTENUATOR and the

HIGH FREQUENCY RESPONSE

The Fairchild 660/670 had a limited high

frequency response, down by several dB at 20

kHz. The primary cause was a low-pass filter

formed by the interaction between the “Miller”

capacitance of the variable-mu tube amplifier

and the impedance of the signal.

What’s “Miller” capacitance?

Vacuum tubes exhibit a tiny amount of

capacitance between the internal electrodes

which is amplified by the gain of the tube,

resulting in an eectively larger capacitance.

This “Miller” capacitance interacts with the

circuit’s impedances, forming a low pass filter

that limits the high frequency response.

A circuit with only one vacuum tube typically

has a small enough Miller capacitance that the

filter has a corner frequency well beyond 20

kHz, having a negligible eect on the sound.

Doubling the number of tubes in the circuit

doubles the Miller capacitance, moving the

corner frequency lower by one octave, and

rolling omore highs.

The Fairchild 660/670 has EIGHT triodes,

adding up to a sizeable capacitance, which

correspondingly moves the corner frequency

to a point within the audible bandwidth.

This was a classic design trade-o, as the

advantage of building a monster compressor

with eight triodes greatly outweighed the

disadvantage of losing a few dB at 20 kHz,

and this gentle high frequency response

characteristic became a part of the Fairchild

sound.

When Electronaut set out to design a modern

“descendent” of the Fairchild 660/670, a

decision had to be made as to whether to

identify this high frequency roll-oas a

problem that should be fixed, or as a feature

that should be preserved. Ultimately, the

point became moot; the M97 can be set to

provide either a Fairchild-like roll-oor a more

modern extended frequency response.

When the INPUT ATTENUATOR is set to any

position other than 0dB, the Miller capacitance

is driven by the attenuator impedance (600

ohms), and the high frequency response is

very similar to the Fairchild 660/670.

When the INPUT ATTENUATOR is set to 0dB,

it is eectively bypassed. This means the

Miller capacitance is driven by the impedance

of the source signal instead of the impedance

of the input attenuator.

Since modern recording systems drive audio

lines at fairly low impedances (often 100

ohms or less), more energy is available to

drive the Miller capacitance when the INPUT

ATTENUATOR is set to 0dB, and this pushes

the pole of the low-pass filter back out to the

ultrasonic range.

Please refer to the frequency response plot

shown in Figure 20.

NOTE:

When setting the INPUT ATTENUATOR to 0dB

for extended high frequency bandwidth, it is

necessary to use a fader or other means to

control the level driving the M97 input, since

the amount of compression is dependent on

input level.

The graph shows several distinct

characteristics:

• With 6dB of attenuation and no

compression, the response is down

approximately 2.5 dB at 20 kHz.

• With the attenuator at 0 dB and no

compression, the response is relatively flat

out to 50 kHz.

The high frequency response is also influenced

to a lesser degree by the limiting action,

which tends to boost the top end slightly,

compensating for the natural roll-o.

• With 6dB of attenuation and 6 dB of

compression, the response is down only

1 dB at 20 kHz.

• With the attenuator at 0 dB and 6 dB of

compression, a boost of nearly 2 dB at 20

kHz can be obtained.

USER’S GUIDE 18

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

THE CONTROLLING AMPLIFIER

DC THRESHOLD

The DC THRESHOLD knob determines at

what level the limiting action begins with the

application of a sine wave or the RMS value

of a complex waveform. Turning the knob

clockwise raises the level at which limiting

action begins. See Figure 21.

Figure 21 — The DC THRESHOLD control raises the

threshold as it is rotated clockwise.

AC THRESHOLD

The AC Threshold is the input attenuator to

the controlling amplifier, which receives its

signal from the output of the audio amplifier.

Used in conjunction with the DC THRESHOLD,

it is set to determine the ratio of compression

during limiting. Turning the knob clockwise

increases the amount of limiter action. See

Figure 22.

Figure 22 — The AC THRESHOLD control increases the

limiter action as it is rotated clockwise.

The AC and DC Threshold are explained

in more detail in the section titled

““UNDERSTANDING the eects of

the AC and DC Threshold controls” on page 20

ATTACK

The attack control determines the speed with

which the limiter attacks a level above the

threshold point, and also determines the ratio

of action the limiter will have on short duration

spikes and transients. Increasing the control

clockwise slows the attack. See Figure 23.

Figure 23 — The ATTACK control slows down the limiter’s

response time as it is rotated clockwise.

USER’S GUIDE 19

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

RELEASE

The release control determines the time-rate

of limiter holding action. Increasing the control

clockwise lengthens the holding time. See

Figure 24

Figure 24 — The RELEASE control slows down the

limiter’s recovery time as it is rotated clockwise.

ATTACK and RELEASE INTERDEPENDENCE

The attack and release controls are

interdependent. The attack control provides

a resistance before the time base capacitor

network with the associated release control,

and the input transformer’s center tap feed

network.

In the extreme counterclockwise positions of

the attack and release controls, the limiter is

intended primarily for peak limiting; where it is

desirable to only trim transients and not limit

the basic program material’s dynamic range.

If program level compression is desired in a

ratio greater than 6:1, the attack and release

controls should be set to 7. As the bass

content of the program material increases it

may be necessary to either:

• increase the release control clockwise to

prevent waveform distortion as the limiter

follows the waveform of the program

signal, or

• engage the high-pass switch

There are no cut-and-dry rules to these

settings; they will need to be determined

through experimentation.

THE USABILITY OF THE FASTEST

ATTACK TIMES

The high-powered controlling amplifier in the

M97 can produce large control voltages very

quickly, allowing a good amount of limiting

and very fast attack times approaching

50 microseconds. Very fast attack times

are useful for limiting brief, short-duration

transients. Typically the DC Threshold control

is used at the higher end of its range to ensure

that only the transient peaks are aected.

Due to the nature of the timing circuits and

the controlling amplifier topology, very fast

attack times cannot be sustained indefinitely.

A good analogy to the fast attack limitaiton

is the classic camera flash found in old-school

analog cameras. The flash was capable of

producing an enormous amount of light, but

could only maintain it long enough for the

shutter to expose the frame. Once the energy

was depleted, a period of time was required to

recharge the flash.

Superficially, the fastest ATTACK times are

similar in that they can produce very large

control voltages very quckly, but for a limited

length of time. For this reason they are ideally

suited for fast-transient peak limiting.

Distortion will be obvious if the ATTACK time

is set to its fastest setting (fully counter-

clockwise) and the M97 is set for heavy

limiting.

If distortion, thumping, or other compression

artififacts are audible, slow down the ATTACK

time until the distortion disappears.

SUGGESTED SET-UP FOR TRANSIENT

LIMITING:

Turn on the TONE and increase both DC and

AC THRESHOLD controls clockwise gradually

until an increase of 10 dB to the input

provides an increase of 2dB at the output. It

is necessary to increase the DC THRESHOLD

control to bring the compression curve

closer to flat as the AC Threshold control is

increased.

The design settings for the DC and AC

THRESHOLD controls at an input level of +4

dBu are 14 and 14 respectively.

Once this setup has been configured, the

INPUT ATTENUATOR can be used to control

the amount of limiting action. If heavier

program limiting is desired: increase the

attack and release controls until waveform

tracking and distortion are eliminated.

USER’S GUIDE 20

ELECTRONAUT COMPANY M97 COMPRESSOR/LIMITER

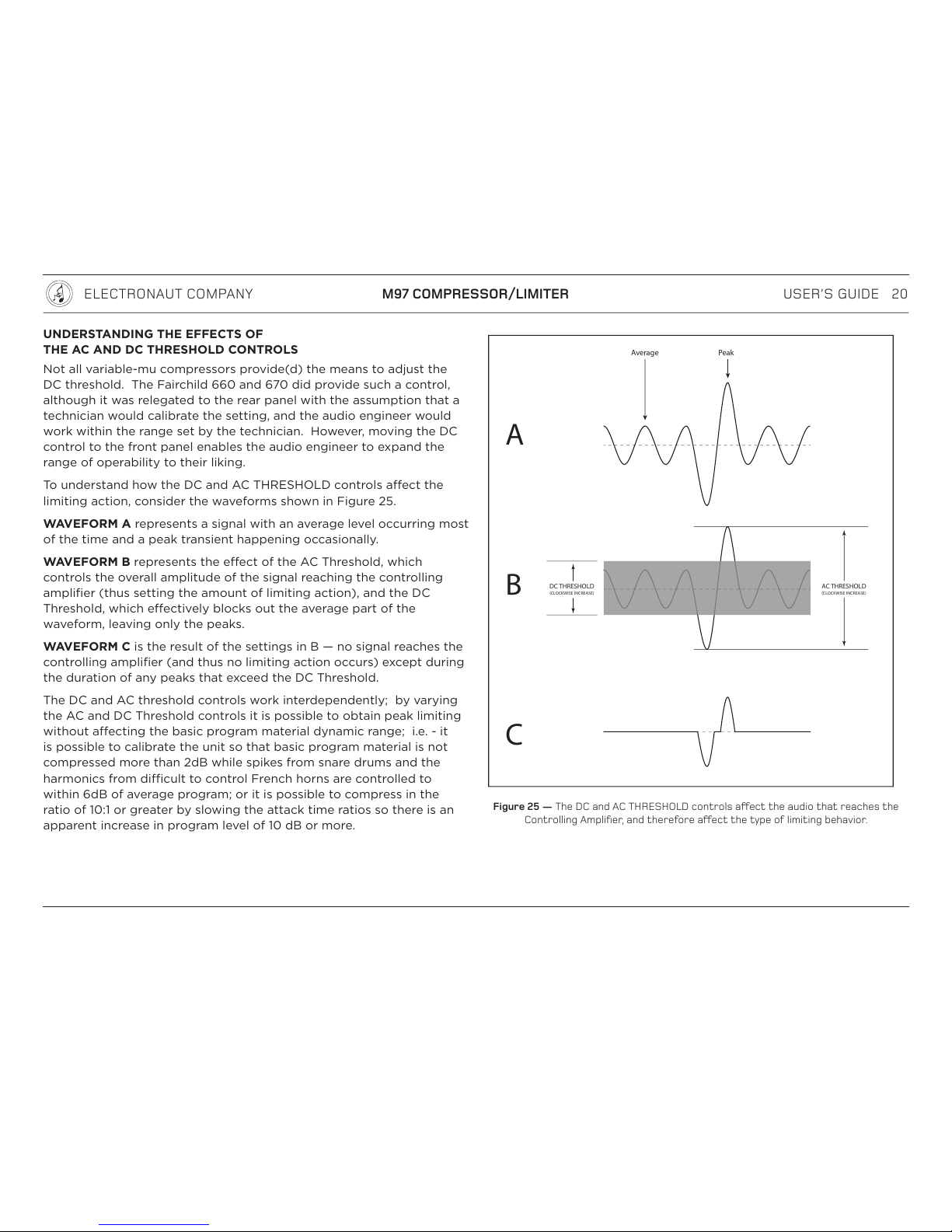

UNDERSTANDING THE EFFECTS OF

THE AC AND DC THRESHOLD CONTROLS

Not all variable-mu compressors provide(d) the means to adjust the

DC threshold. The Fairchild 660 and 670 did provide such a control,

although it was relegated to the rear panel with the assumption that a

technician would calibrate the setting, and the audio engineer would

work within the range set by the technician. However, moving the DC

control to the front panel enables the audio engineer to expand the

range of operability to their liking.

To understand how the DC and AC THRESHOLD controls aect the

limiting action, consider the waveforms shown in Figure 25.

WAVEFORM A represents a signal with an average level occurring most

of the time and a peak transient happening occasionally.

WAVEFORM B represents the eect of the AC Threshold, which

controls the overall amplitude of the signal reaching the controlling

amplifier (thus setting the amount of limiting action), and the DC

Threshold, which eectively blocks out the average part of the

waveform, leaving only the peaks.

WAVEFORM C is the result of the settings in B — no signal reaches the

controlling amplifier (and thus no limiting action occurs) except during

the duration of any peaks that exceed the DC Threshold.

The DC and AC threshold controls work interdependently; by varying

the AC and DC Threshold controls it is possible to obtain peak limiting

without aecting the basic program material dynamic range; i.e. - it

is possible to calibrate the unit so that basic program material is not

compressed more than 2dB while spikes from snare drums and the

harmonics from dicult to control French horns are controlled to

within 6dB of average program; or it is possible to compress in the

ratio of 10:1 or greater by slowing the attack time ratios so there is an

apparent increase in program level of 10 dB or more.

DC THRESHOLD

(CLOCKWISE INCREASE)

AC THRESHOLD

(CLOCKWISE INCREASE)

A

B

C

Average Peak

Figure 25 — The DC and AC THRESHOLD controls aect the audio that reaches the

Controlling Amplifier, and therefore aect the type of limiting behavior.

Table of contents