GIEBEL FilTec GmbH | info@giebel-adsorber.de | Accessories & Spare parts: shop.giebel-adsorber.de 8/8

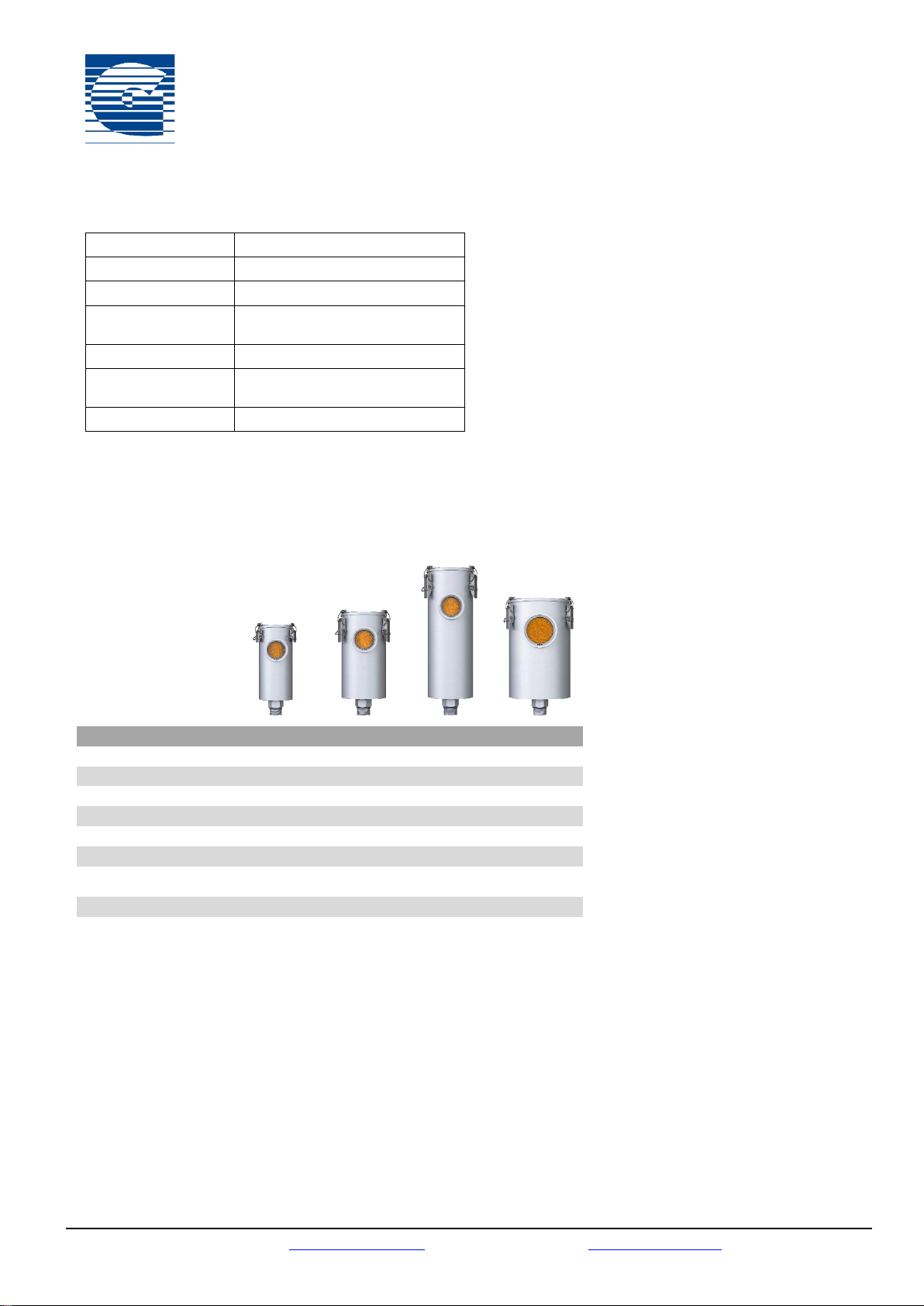

2. Visual inspection of the silica gel

Check The loading condition of the silica gel must be determined by visual inspection of the

adsorber. The colour orange indicates that the silica gel can still adsorb water and air is

dehumidified. When the silica gel is completely saturated, the colour changes to green or

colourless.

If there are oil particles on the silica gel, these close the pores and the adsorption capacity

is reduced. This causes the silica gel to discolour more slowly and unevenly.

Cycle Half-yearly

Measures If the silica gel is loaded or damaged by oil, a new spare parts kit or a new adsorber with

fresh silica gel should be used.

3. Check filter unit for impurities

Check Take off the lid and remove the activated carbon disc. Then empty the desiccant. The filter

unit can then be removed. This should be checked for contamination and should be free of

dirt for smooth operation.

Cycle Half-yearly

Measures The filter element is part of the spare parts kit and should be replaced if it is contaminated.

4. Visual inspection of the adsorber

Check The adsorber must be checked visually for damage. Damage can occur due to various

environmental or operating conditions.

Zyklus Yearly

Measures If the adsorber is damaged, it must be completely replaced to ensure full functionality.

5. Replacing the wearing parts

Check The wearing parts, in particular the seals, the silica gel as well as the adsorber housing,

must be checked with regard to their condition.

Cycle Every two years

Measures Regardless of the result of the test, it is recommended to replace the wearing parts by

using a spare parts kit or a new adsorber to ensure smooth operation.