9

1.2 Positioning

The appliance was designed to be installed in enclosed spaces. It cannot

be used outdoors and must be exposed to atmospheric agents.

The place designated for the installation of the

appliance must have a rigid, level and horizontal

surface, which must be able to safely support

the weight of the appliance (approx. 150 kg) and

the load at maximum capacity.

The appliance must be transported on wooden

pallets using suitable means and must handled

using all necessary precautions to prevent over-

turning.

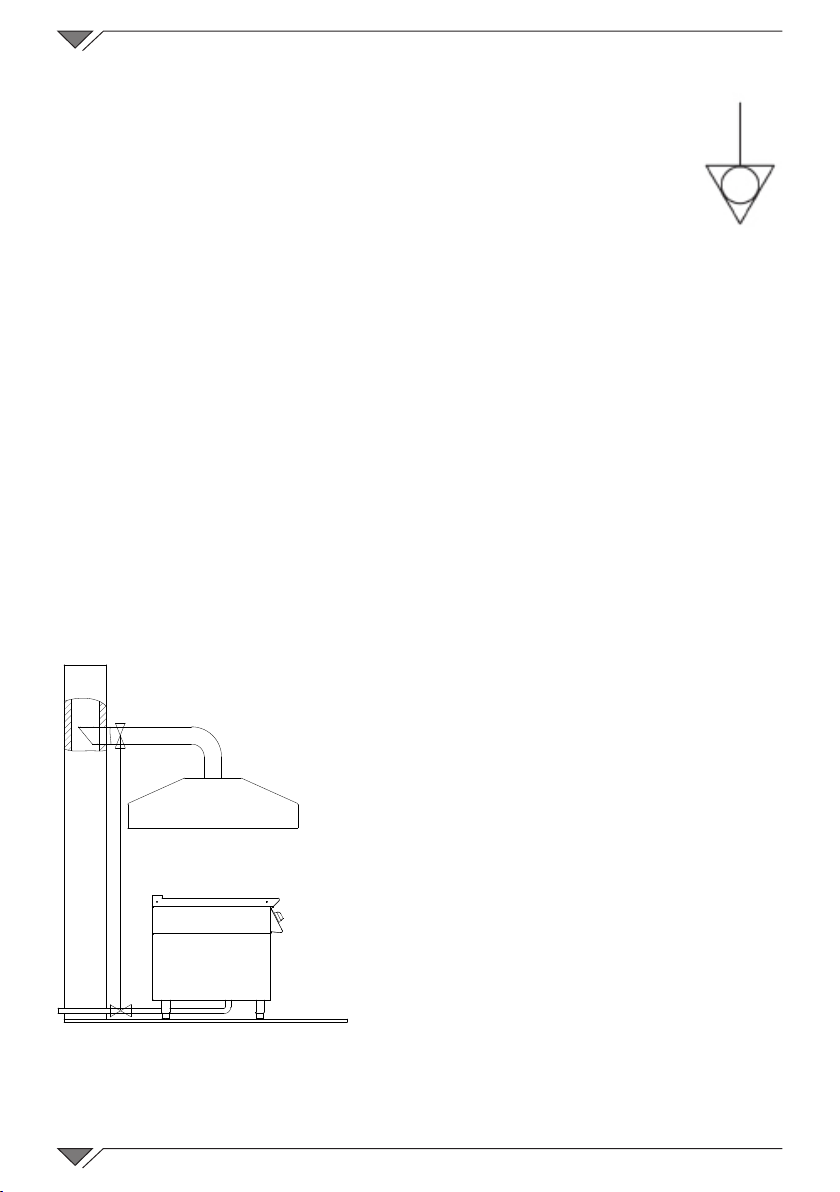

The appliance must be installed at a minimum

distance of 100 mm from the side wall and 50

mm from the rear wall (Fig 1).

All of the materials used for packaging are

compatible with the environment, they can be stored without danger or

be disposed of according to local regulations.

Remove the appliance from the

packaging and inspect it for damage,

then position it in the place of use.

Ensure the appliance rests on a level

oor and adjust the height via the

levelling feet as shown in Fig 2.

Signicant unevenness or inclinations

can compromise the operation of the

oven.

The oor of the premises where the appliance is installed must be re-

proof.

If the appliance is placed against a wall, this must be able to withstand

temperatures of 80°C and if it is ammable, heat insulation must be

installed.

Remove the entire protective lm from the external panels of the

appliance, detaching it slowly to remove all traces of adhesive.

Make sure that all openings and holes designed for heat intake/discharge

are not obstructed.

Do not block the intake or heat dissipation openings and vents and

place the appliance beneath an extractor hood whose system must be

legally compliant.

100

50

Fig. 1