GIPPSLAND AERONAUTICS SECTION 1

Model GA8 GENERAL

GA-FM-04 Owners and Pilots Information Manual Page 1-5

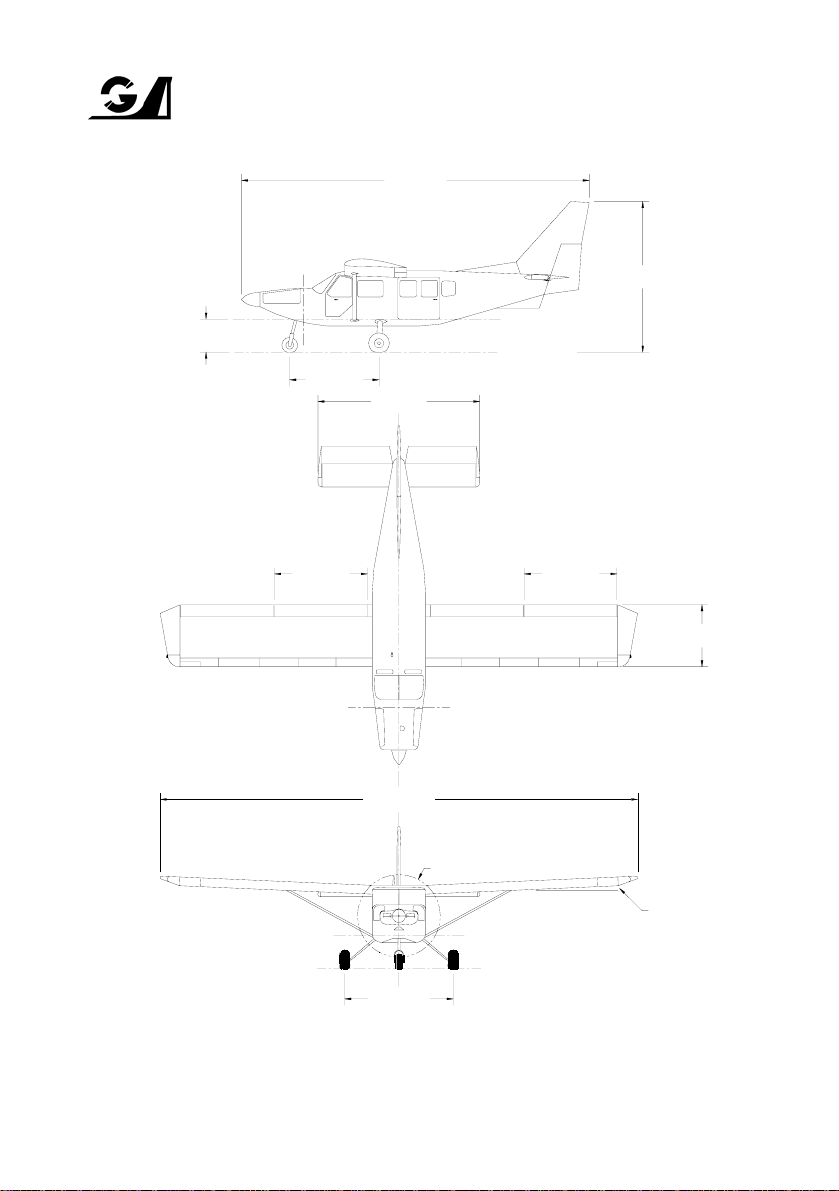

1.2 GENERAL DESCRIPTION

1.2.1 Aircraft

The GA8 aircraft is a strut braced, high wing, fixed tricycle undercarriage, single engine,

eight seat cabin aircraft that has been designed primarily for passenger and utility

operations.

The fuselage is an all alloy stressed skin construction and is fully corrosion protected. The

floor of the passenger cabin is provided with a quick release system to allow rapid

conversion from freight to passenger or combi configurations. The engine cowlings are

manufactured from composite materials and feature large, easily removable access panels.

The cockpit is designed to accommodate the pilot in command on the left side and all

controls, instruments, selectors and switches are located so as to be within easy reach of

the occupant of that seat. A second, optional set of flight controls and instruments may be

fitted to the right side front seat position. The centrally located control pedestal, radio stack

and overhead switch panel are accessible from either of the two cockpit seats. The cockpit

is accessed by forward hinging doors that are located on each side. The main cabin is

provided with a large sliding door on the left side at the rear of the fuselage.

The wings are of all metal stressed skin construction with full corrosion protection, and are

braced on each side by a single streamlined bracing strut. A single integral fuel tank is

located in each wing between the fuselage and the strut. The ailerons and wing flaps are of

metal construction and operate in a conventional sense.

The empennage is also an all metal stressed skin construction and is fully corrosion

protected. A variable incidence stabiliser is incorporated to provide a wide trim range with

maximum aerodynamic efficiency. The vertical surfaces feature a half span rudder that is

located on the lower portion of the fin.

1.2.2 Engine

The engine is a, six cylinder, horizontally opposed, air cooled, normally aspirated and fuel

injected Lycoming IO-540-K1A5 rated by Lycoming to 300 BHP at full throttle and 2700

RPM. Operations at 2700 RPM are limited to a maximum period of two minutes. Except for

take-off, normal full throttle operations are conducted using 2500 RPM.