KIT: P/N 938-02000-01

KIT INSTRUCTIONS: P/N 063-09019-01

REVISION: C DATE: 8/28/08 PAGE: 2

2008©Copyright Glasair Aviation LLC, Arlington, Washington All rights reserved

Step 1: Cut Out the NACA Scoop in the Fuselage

Side

Figure 6 on the last page of these instructions is a full-size template

of the NACA scoop for the cabin air vents. Glue this template to a

piece of stiff cardboard and cut it out.

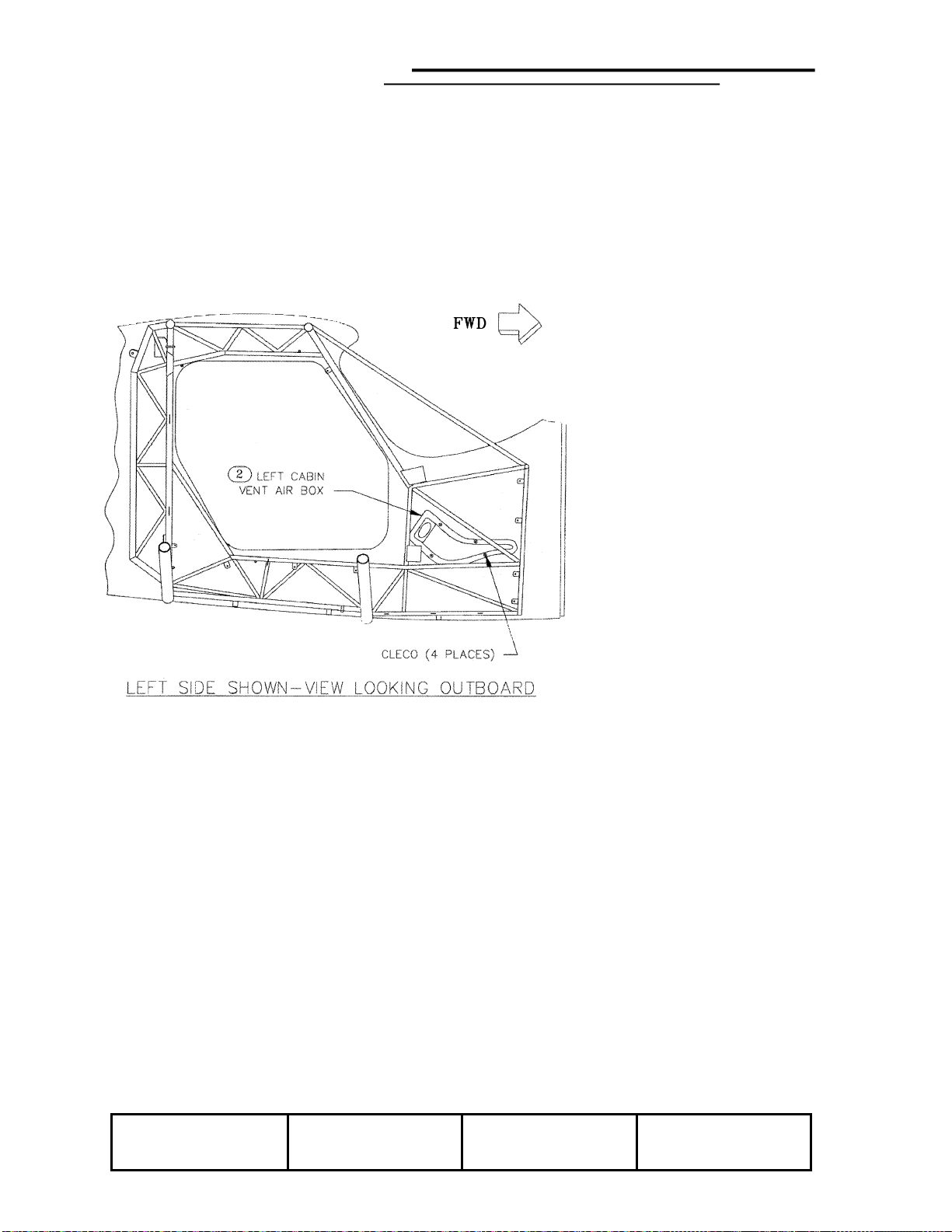

Figure 1 shows how the template should be positioned on the

outside of the fuselage shell. The narrow forward edge of the

template should be positioned 3 ½” aft of the cowling attach flange

joggle, and the centerline of the template should be parallel to and

8” below the waterline of the aircraft.

CAUTION: The NACA scoop cutout location given above is taken

from one of our GlaStar / Sportsman demonstrators. However, early

customer experience suggests that, due to variations in the position of

the cage relative to the shells, the specified cutout location may lead to

interference between cage tubes and the cabin air vent boxes.

Therefore, treat this location as provisional until you have verified

clearance, as described below.

Tape the template in position on the exterior of the fuselage shell.

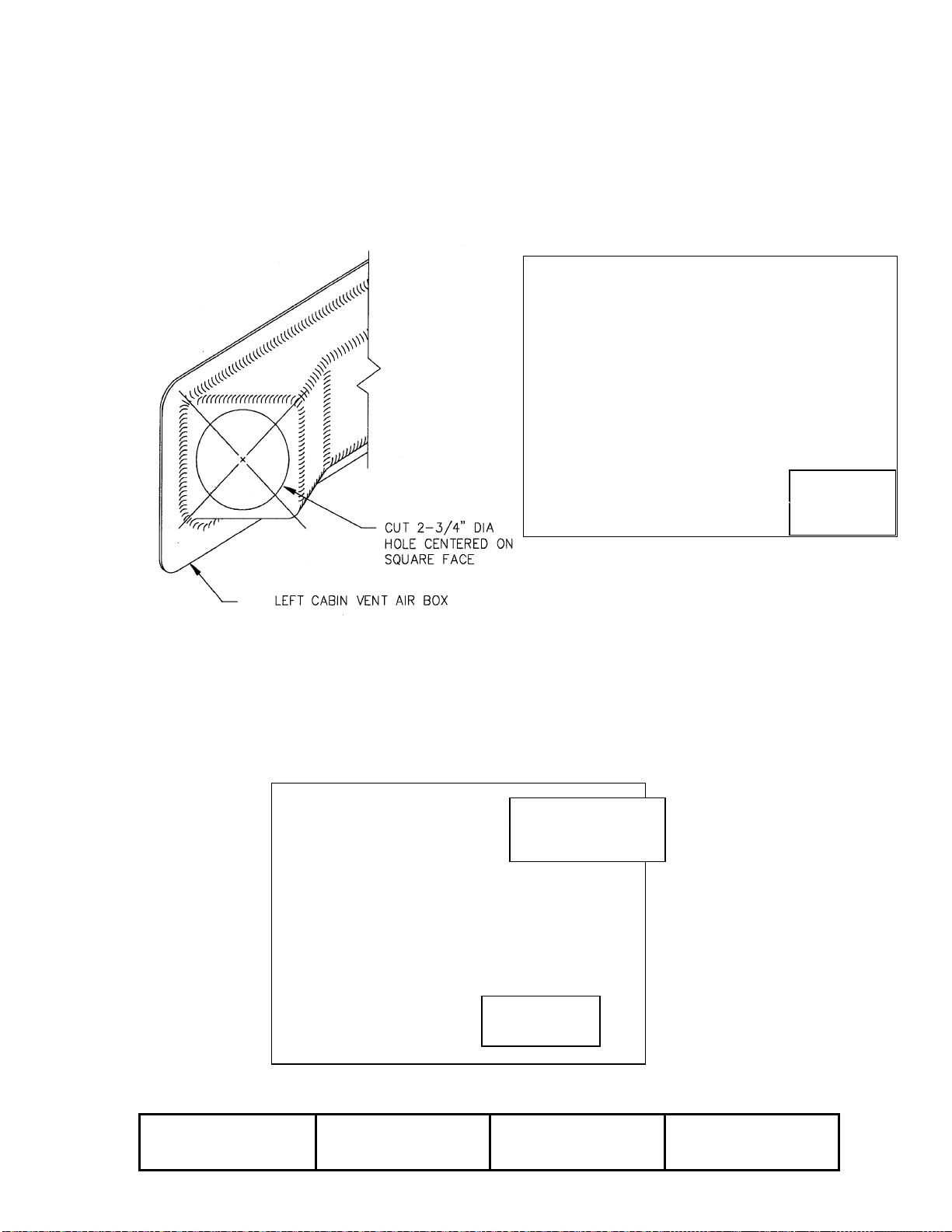

Then position the appropriate air box on the inside of the shell

opposite the template so that the NACA scoop-shaped portion of

the box is aligned with the template (see Figure 3). The box should

clear all cage tubes when pressed against the fuselage shell.

Check both sides and adjust the position of the cutout as necessary

before cutting into the shell. It is acceptable to move the location

as much as several inches from that specified above; however,

take reasonable care to keep the centerline of the cutout parallel

with the aircraft waterline. When you are satisfied that both boxes

will clear, trace around the perimeter of the template with a marking

pen. Then cut all the way through the fuselage shell, removing the

material inside the marked line. Cut slightly inside he line initially

and then finish up the cutout with a file and sandpaper.

CAUTION: Take care not to damage the cage structure behind the

fuselage shell as you make the NACA scoop cutout.

Completed: Left [ ] Right [ ]