M A I N T E N A N C E P R I N C I P L ES

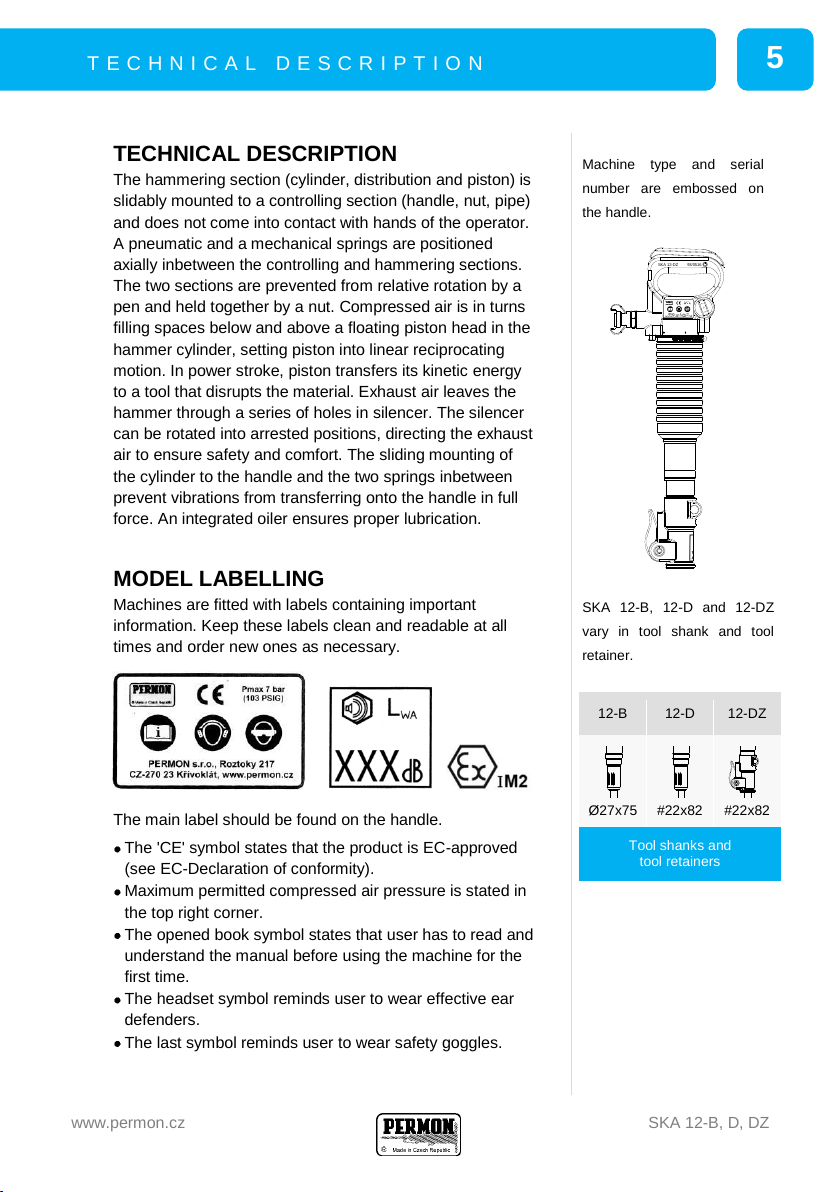

Guaranteed noise level in accordance with Directive

2000/14/EC is indicated by a label under silencer, and a

mark on the silencer marks the group and category the

machinery falls under in accordance with Directive 94/9/EC

–ATEX.

MAINTENANCE PRINCIPLES

Only personnel properly acquainted with the structure and

function of the hammer can service the tool.

All repairs are to be performed by the manufacturer or

authorized trained personnel.

Dry, clear air of the appropriate overpressure

(see Technical data) must be available in

sufficient volumes.

Supply hose must match the prescribed dimensions.

To avoid excessive frictional pressure loss, do not use

hoses of over 15 meters in length (in case of a Js16

hose). If necessary, hose of a larger diameter can be

used over greater distances.

Protect the hammer from dirt and other harmful

particles getting in. Always keep the input and output

openings clean.

Blow the hose clear to get rid of potentially harmful

particles before attaching it to the hammer.

Properly tighten all joints and re-tighten after 3-5 hours

of first operation.

Check-up on the state of the hammer regularly.

Hexagonal chuck in SKA 12-D and 12-DZ makes use

of chisel type tools possible. The open screw retainer

can be used for wider chisels and facilitates faster tool

replacement. If the hammer operates without sufficient

thrust, the screw retainer can crack under heavy

impacts of the tool!

LUBRICATING

Lubricate the hammer properly to secure maximum service

life of sealing rings of the handle. Damaged rings let air

escape the handle body, limiting vibration dampening or

rendering it virtually ineffective. Sufficient lubrication is

secured with an oiler integrated in the handle. The oiler

needs to be re-filled before every work shift.

Alternatively, pour about 100 cm3of oil into the air supply

hose (at the entry point) by the compressor unit and 5 cm3

into the air inlet at the beginning of each work shift and

repeat every 2-3 hours of operating.

Thrust

With regards to vibrations

and manipulation of the

hammer, the optimal thrust is

between 150 –200 N.

The thrust must prevent the

hammer from working idly,

which increases wear and

chance of breakdown.

Tool insertion

Unscrew retainer with ring.

Always check the state of

rubber ring. Insert tool into

cylinder and screw retainer

back on.

The SKA 12-DZ version with

latch retainer comes without

a ring. Insert tool by tilting

the latch and then close the

retainer.

Never start a hammer

without a tool inserted!