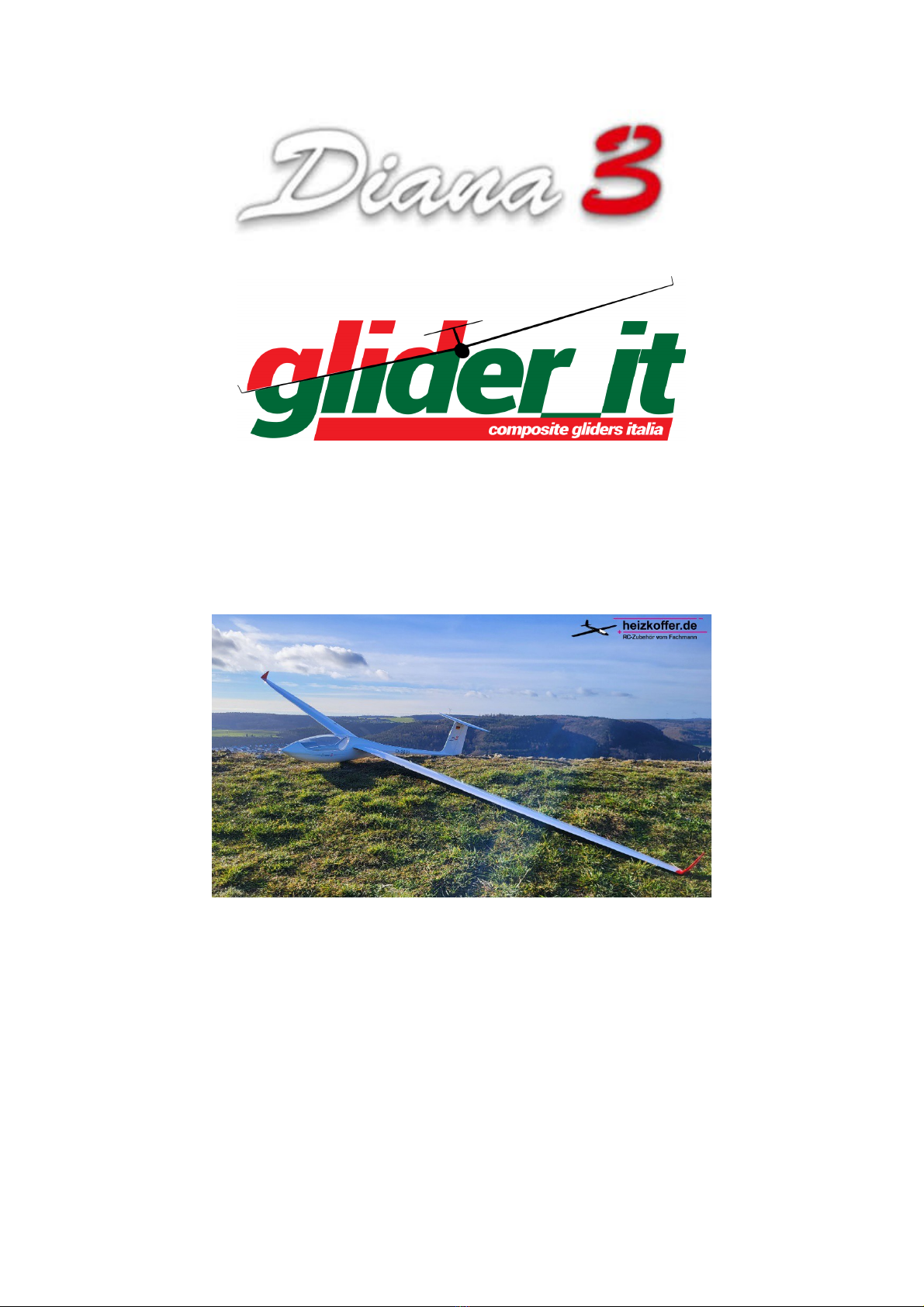

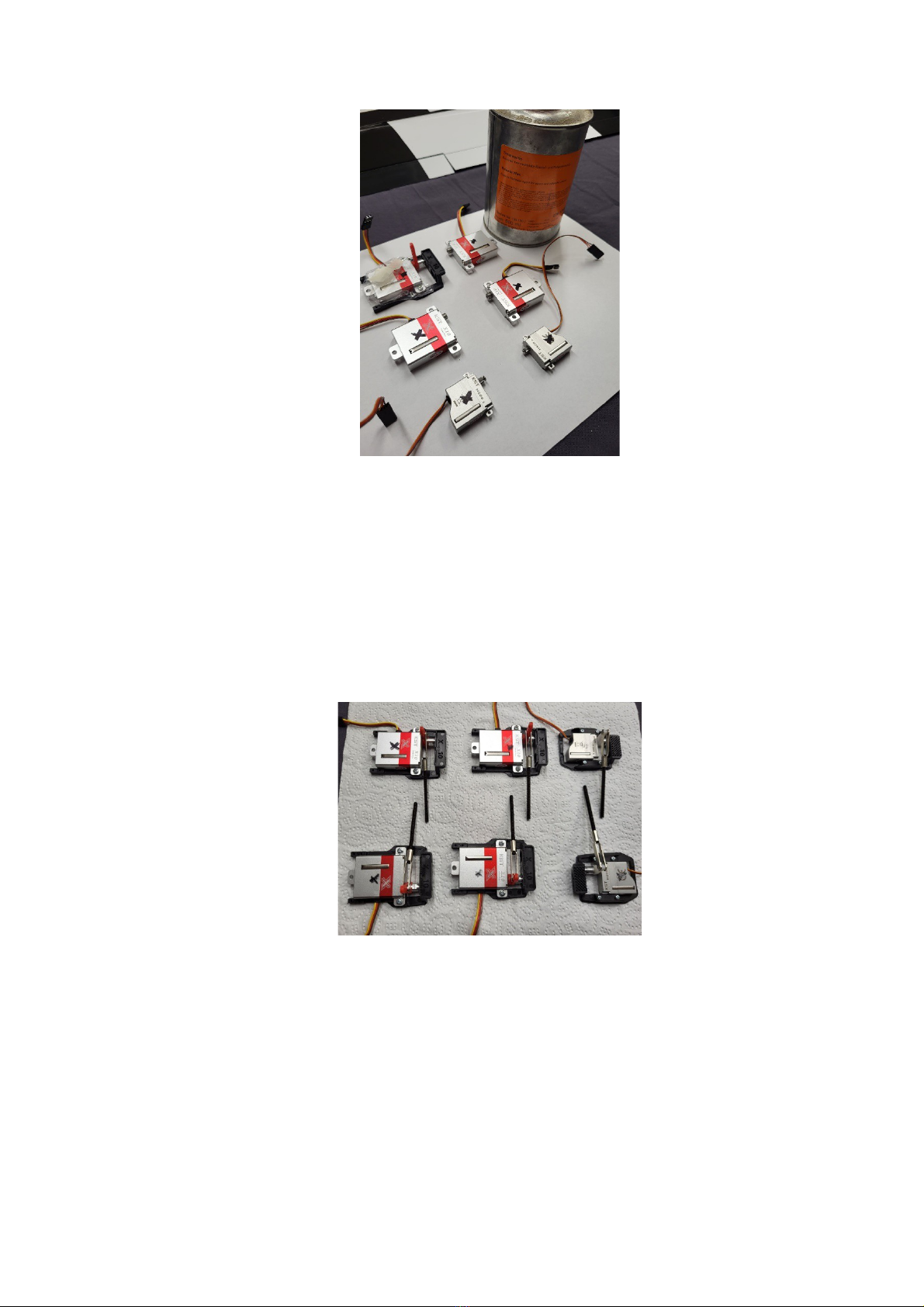

- Now all servos are screwed into their frames.

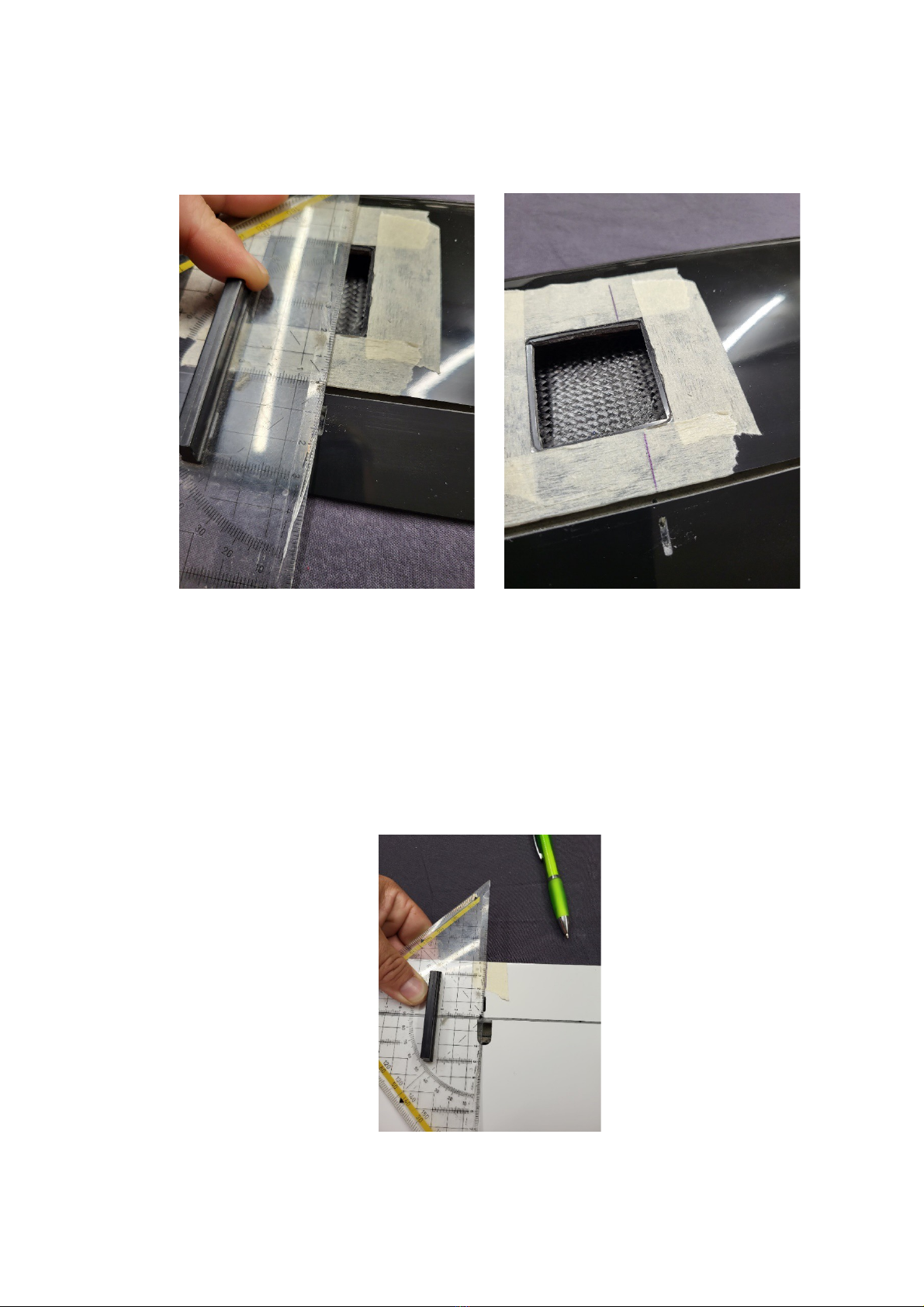

Important: With servo arm, fork head and a linkage (the length of the

linkage does not matter here)

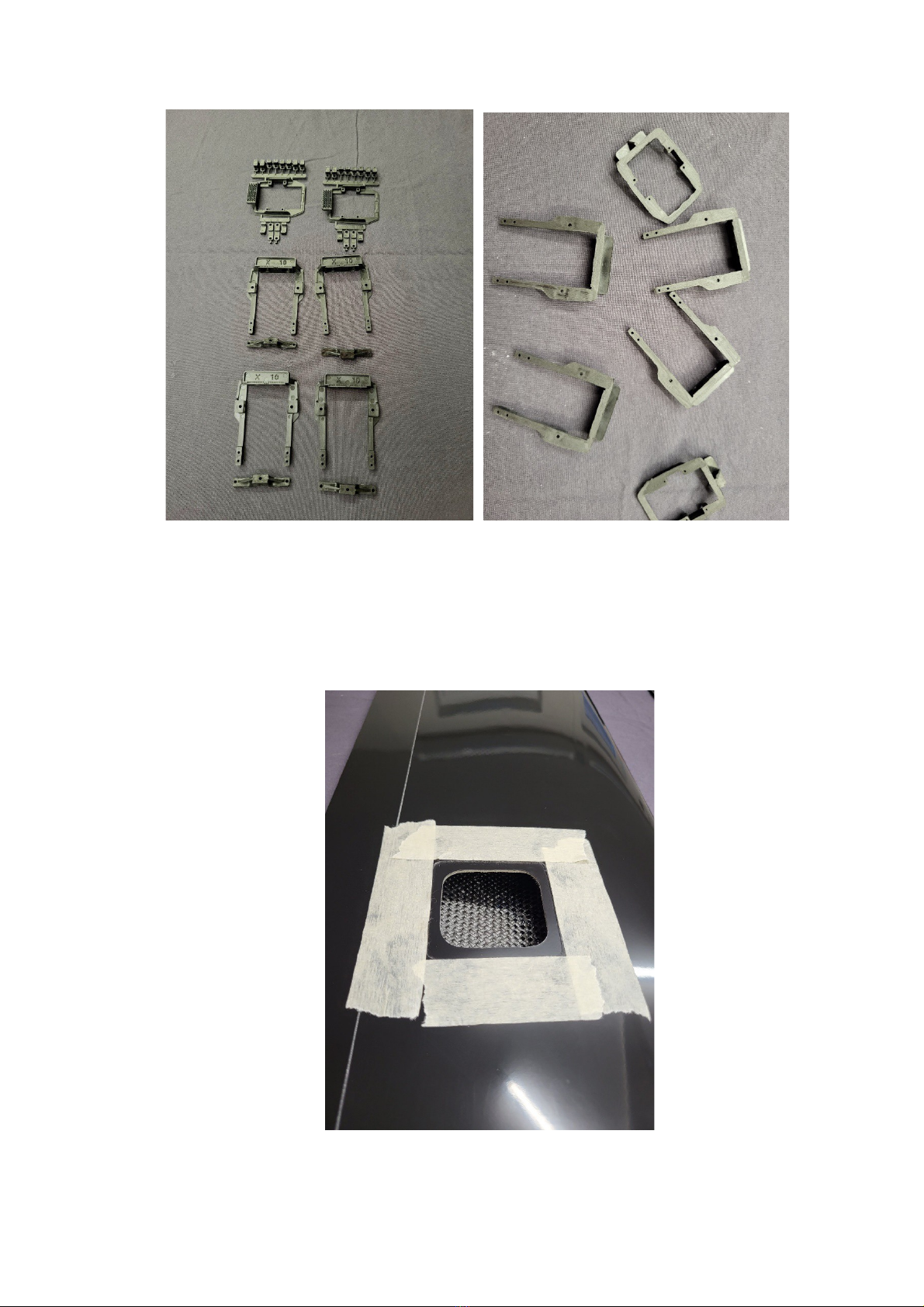

The rear crossbar on the X10 can be omitted. The servo is fixed at 3

points (2 screws + the counter bearing) and this is sufficient

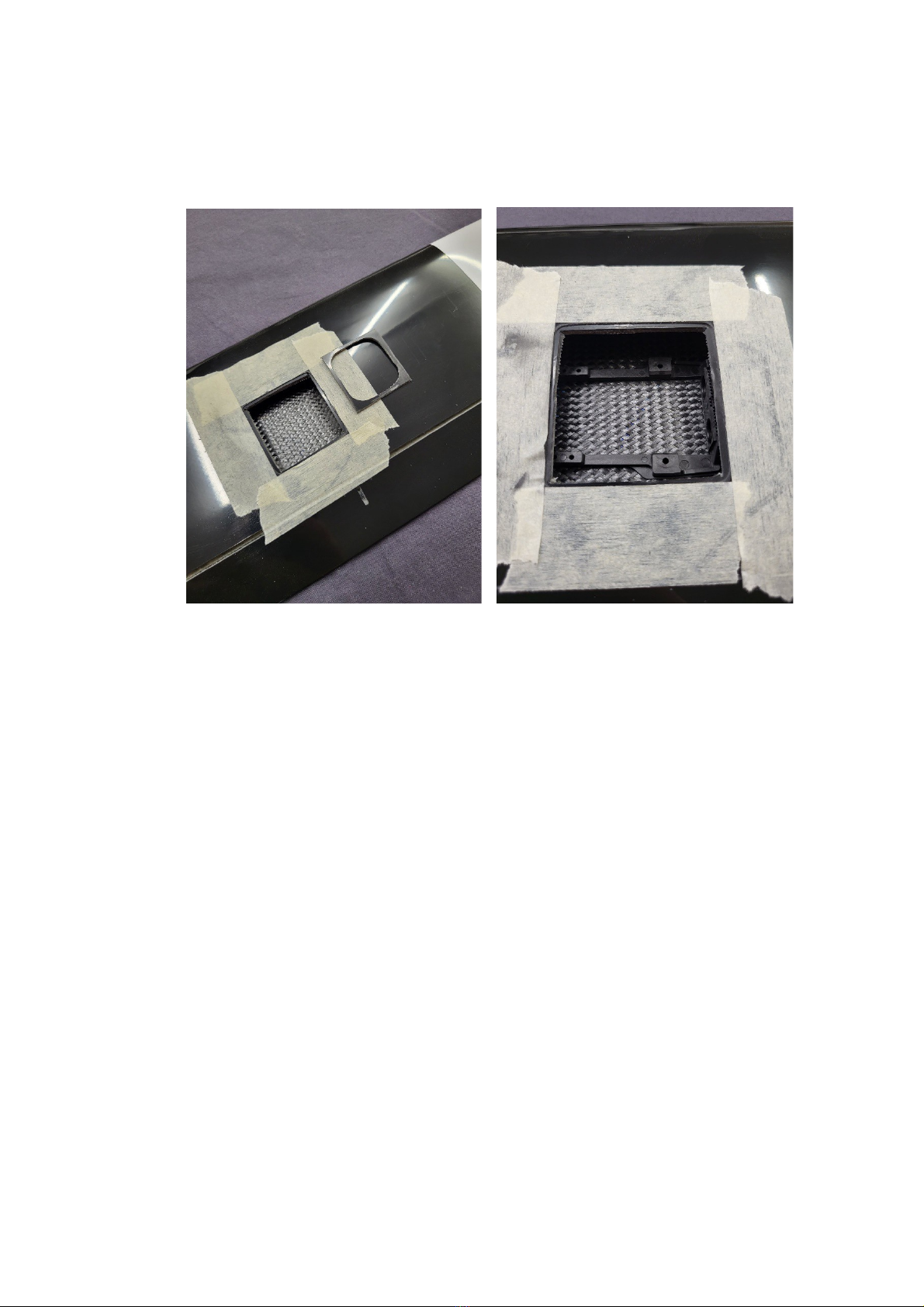

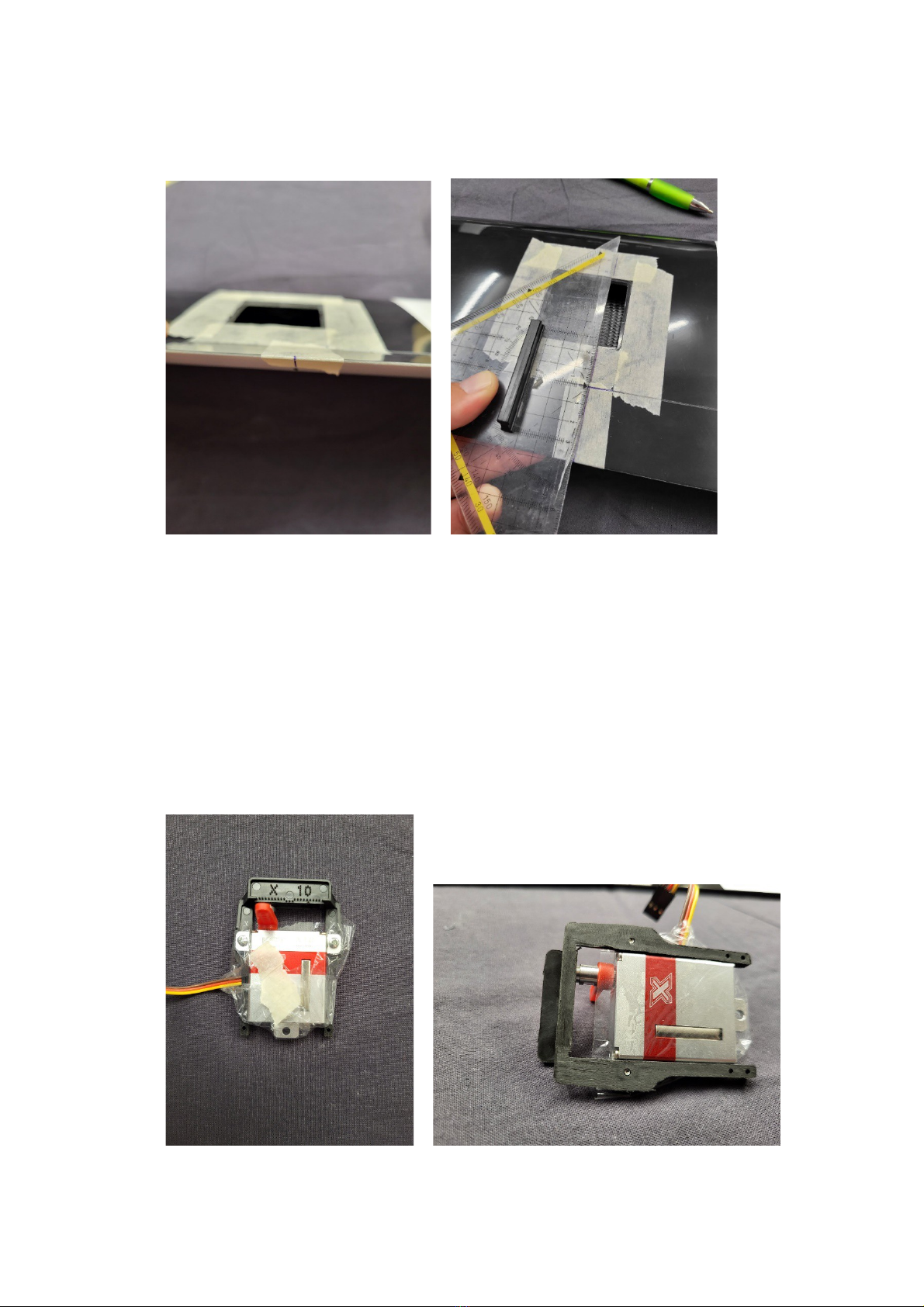

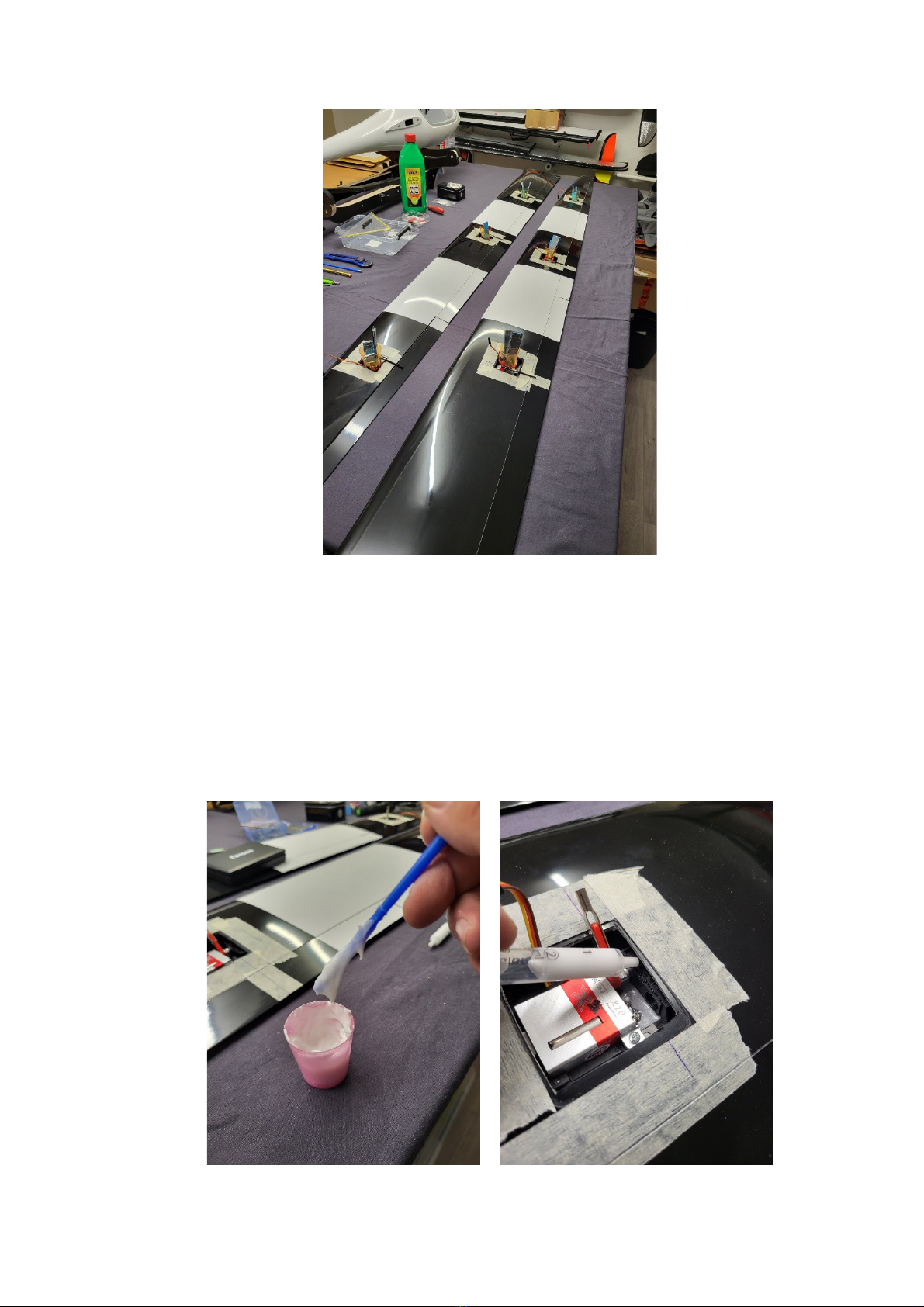

- Now the 6 servo frames can be glued in. For this they either use Uhu

Endfest or you mix a mumble of 24h resin with cotton flakes and some

thixotropic agent.

If your glue is ready, wet the places in the servo bay and the servo

frames with the glue with a brush. Place the servo frames in the desired