1

Using two or more people, place the

mill on a sturdy table, desk or

countertop capable of supporting

150 lbs. Make sure the mill has at

least a four-inch clearance on all

sides.

WARNING: To prevent injury, two

or more people should lift and

place the mill in its location.

2Set up the computer components:

monitor, keyboard and mouse close

to the mill.

3As a safety precaution, always

connect the power cords for the mill,

computer and monitor to easily

accessible three-pronged grounded

power outlets.

WARNING: Make sure the power

cord connections are accessible

at all times so disconnections can

be made during an emergency.

4Connect the computer to the mill

with the USB cable.

5Make the coolant using the

directions in the Preparing Coolant

section on page 14. (Coolant warning

and hazard information are in the

Routine Maintenance and Operations

section of these instructions.)

6Pour the prepared coolant into the

trough to the MAX ll line (1500 mL)

on the right side of the trough.

7Slide the trough into the mill until it

clicks into the locked position with

the trough door completely closed.

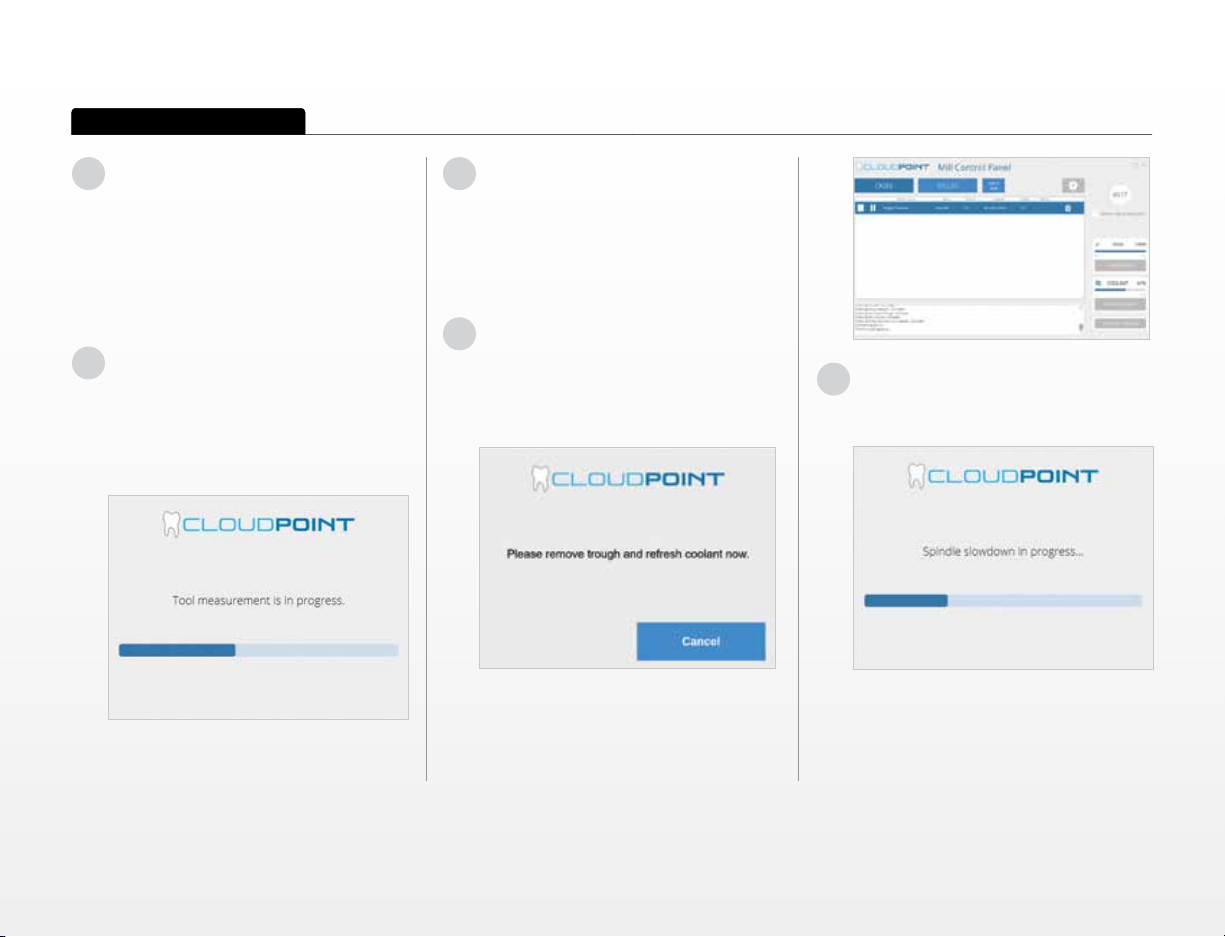

8Turn on the computer and the mill.

The CloudPoint®Mill Control Panel

will open onto the computer screen.

9Click “CHANGE TOOL.”

Page 6 of 22

Initial Setup

Inital Setup