Table of contents

1General information.............................................................................................................................................................................3

1.1 Introduction............................................................................................................................................................................................3

1.2 Purpose.................................................................................................................................................................................................3

1.3 Contact..................................................................................................................................................................................................3

2Personal protective equipment (recommended by Global Gravity).................................................................................................4

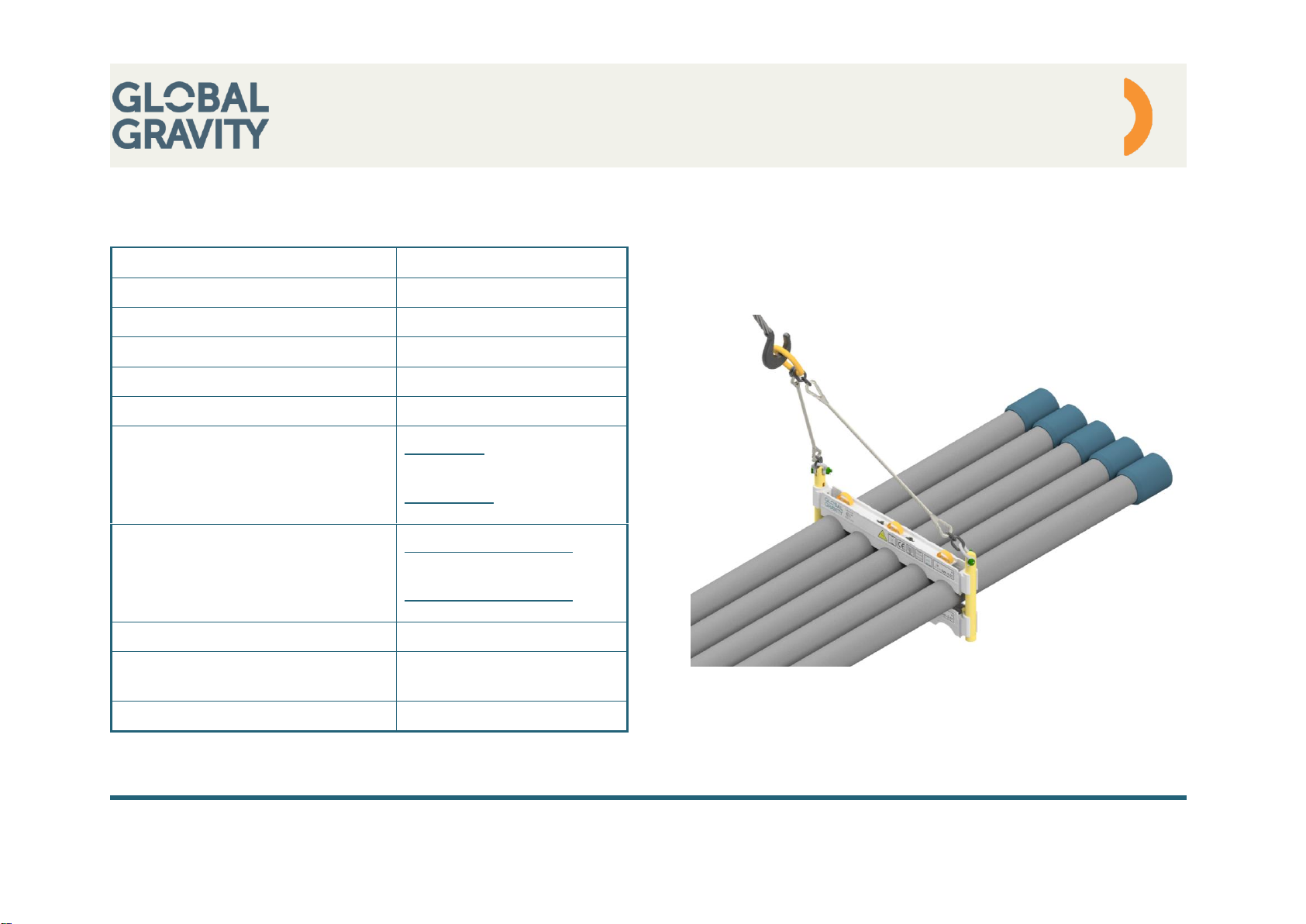

3System data .........................................................................................................................................................................................5

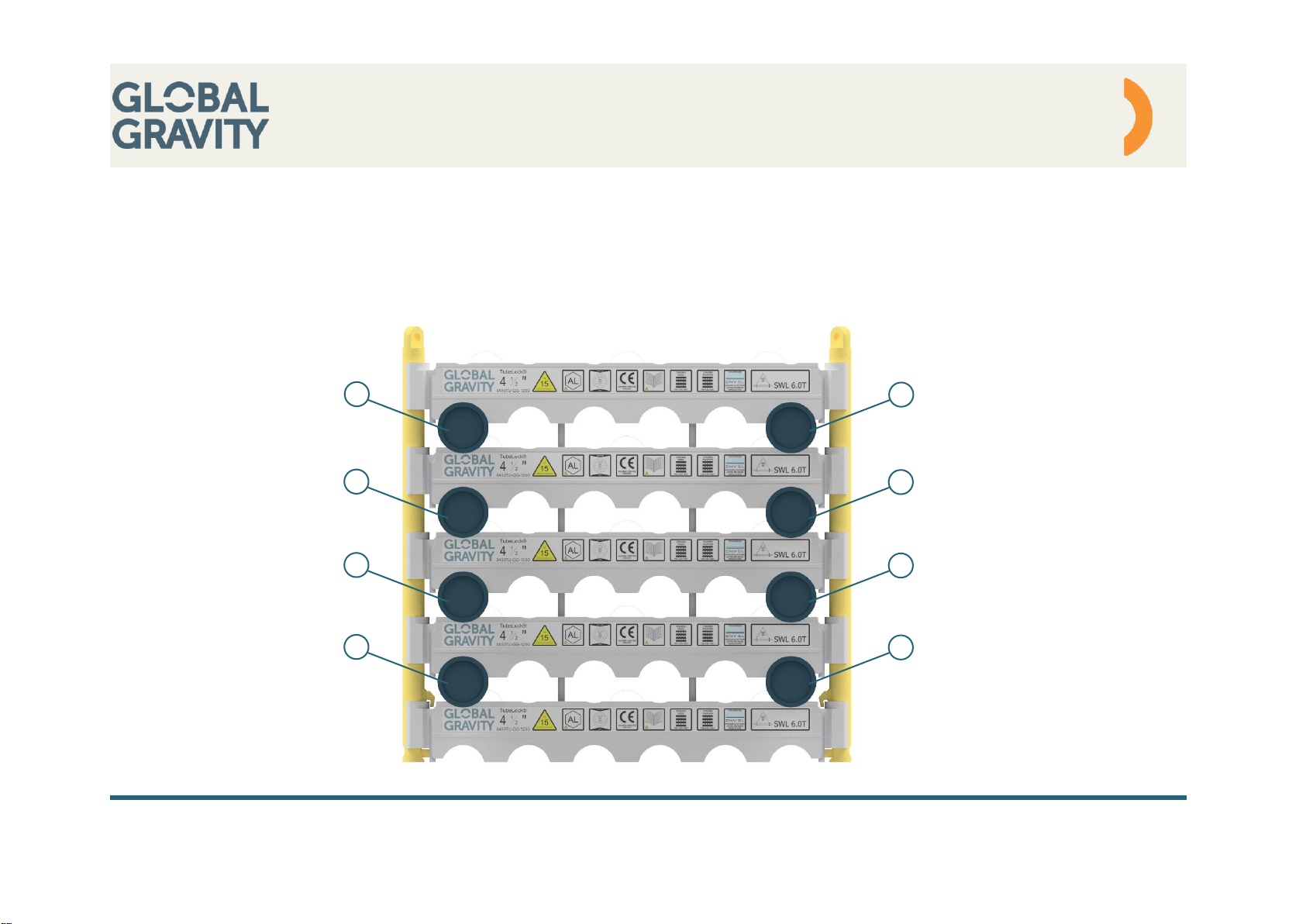

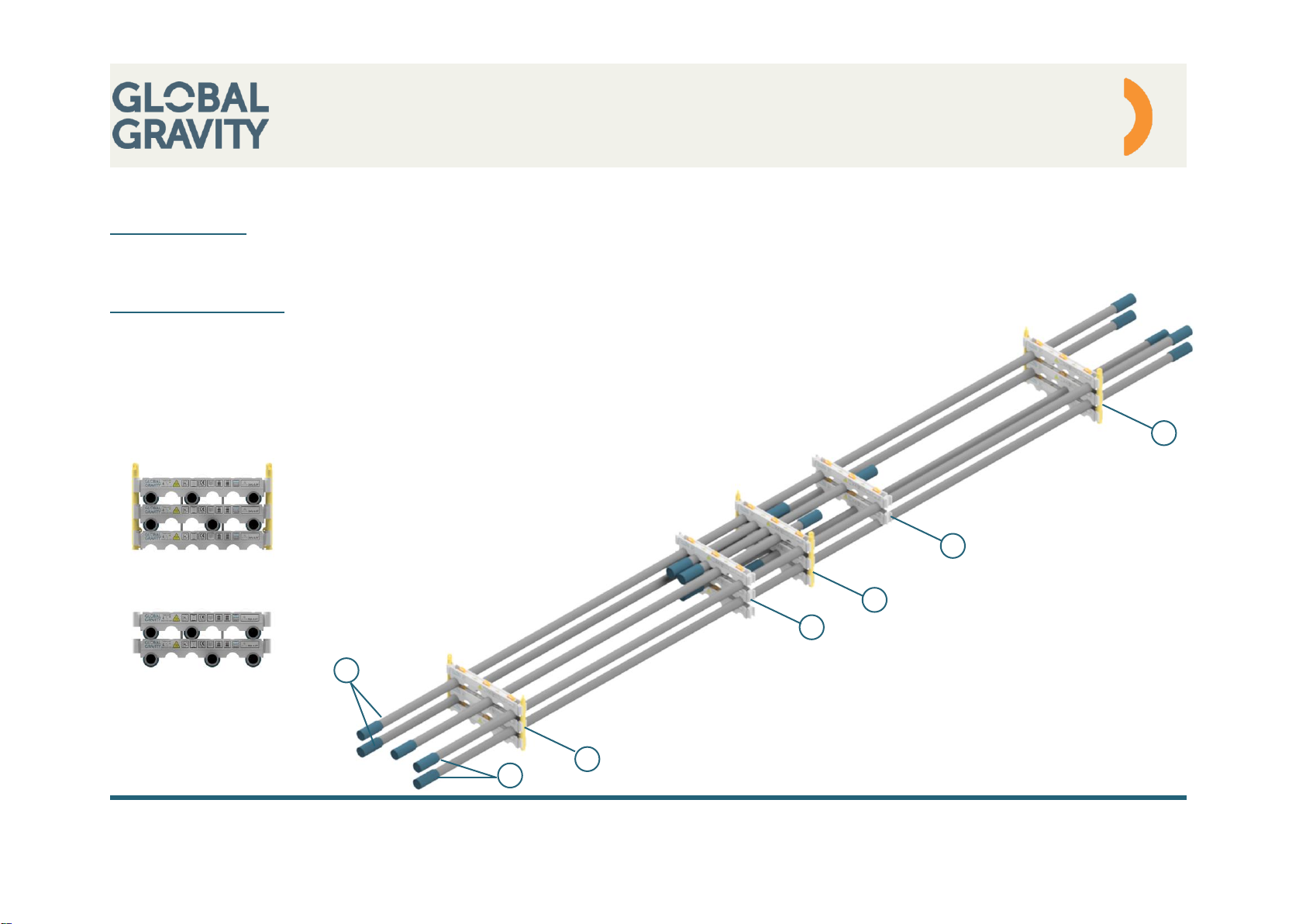

4Layout...................................................................................................................................................................................................6

4.1 Package assembly.................................................................................................................................................................................6

4.2 Packing configuration –Empty spaces ..................................................................................................................................................7

4.3 Packing configuration –Different pipe length.........................................................................................................................................8

4.4 Exploded view .......................................................................................................................................................................................9

4.5 Component overview...........................................................................................................................................................................10

5Packing instruction ...........................................................................................................................................................................11

6Slings / Stacking................................................................................................................................................................................16

7Placing on the drilling rig..................................................................................................................................................................18

8Service................................................................................................................................................................................................21

9Handling.............................................................................................................................................................................................22