2. CAUTION

1. Hazard or unsafe practice, which, if not avoided, may result in PERSONAL INJURY

and PROPERTY DAMAGE.

2. READ THE OPERATION MANUAL COMPLETELY BEFORE USING AND

THOROUGHLY UNDERSTAND AND FOLLOW ALL SAFETY INSTRUCTIONS.

3. This lifter is designed for use with stable uniform load on a solid lever floor. DO NOT use the

lifter for any other purpose than its intended use.

4. Only TRAINED personnel shall operate lifter. OPERATORS shall read this manual

completely and thoroughly understand the controls and operation of this equipment

BEFORE operating the lifter.

5. ALWAYS observe lifter and ALWAYS stay at the controls while the lifter is in motion. RELEASE

controls and STOP lifter immediately if load on lifter appears to become unstable. NEVER

leave the loaded lifter unattended unless the table is in the fully lowered position and the

lifter is locked.

6. DO NOT slide the load on or off the table. The lift may move allowing the load to fall. SEVERE

PERSONAL INJURY and PROPERTY DAMAGE could result.

7. DO NOT use lifter with unstable, unbalanced or loosely stacked load. Unbalanced loads

may become unstable and fall. This can cause SEVERE PERSONAL INJURY and

PROPERTY DAMAGE

8. Qualified personnel must perform ALL lifter service only.

9. ALWAYS keep feet, hands and fingers away from casters, load wheels and all moving

components.

10. ALWAYS perform maintenance and inspections with lifter unloaded.

11. Prolonged continuous working might cause damage of power pack.

12. Stop operation if temperature of hydraulic oil is too high.

The lifter is NOT waterproof and is intended to be used in a dry environment.

3. DAILY INSPECTION

Daily inspection is effective to find the malfunction or faulty on the lifter. Check the lifter on the

following points before the operation.

CAUTION

DO NOT use lifter if any malfunctions are found.

(1) Check for scratches, deformations, or cracks on the lifter.

(2) Ensure wheels move smoothly.

(3) Check if there is oil leakage.

(4) Check for vertical creep of the table.

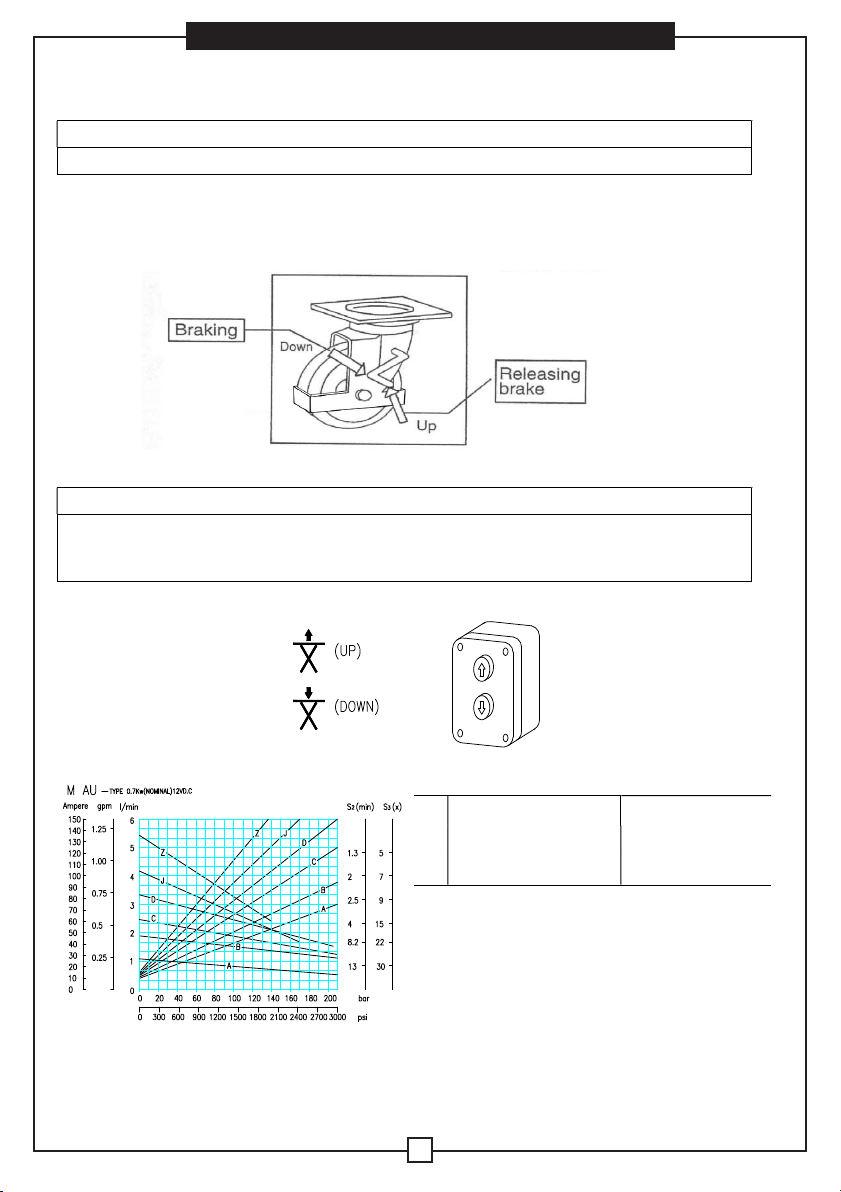

(5) Check the brakes.

(6) Check if all the bolts and nuts are tightened firmly.

Battery Powered Scissor Li

3