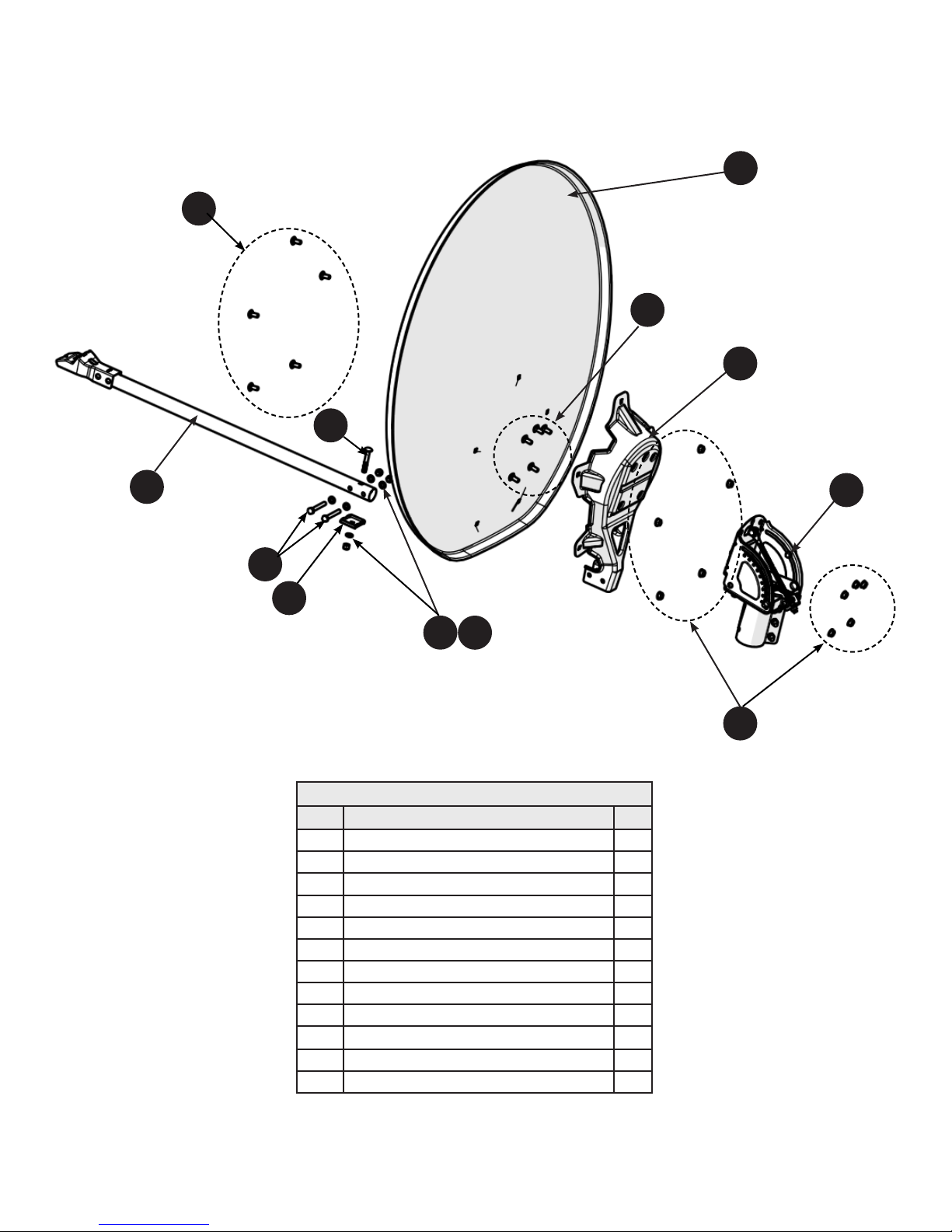

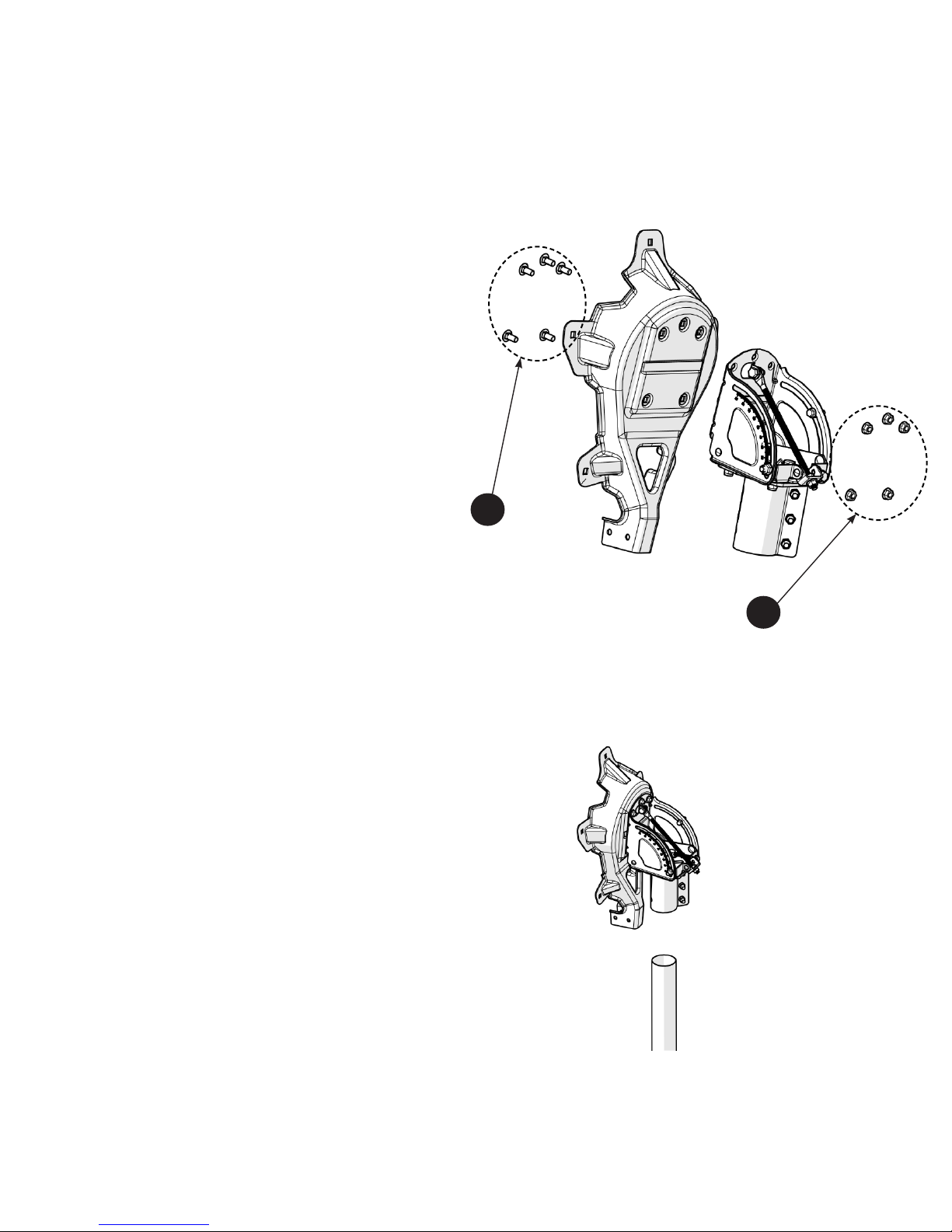

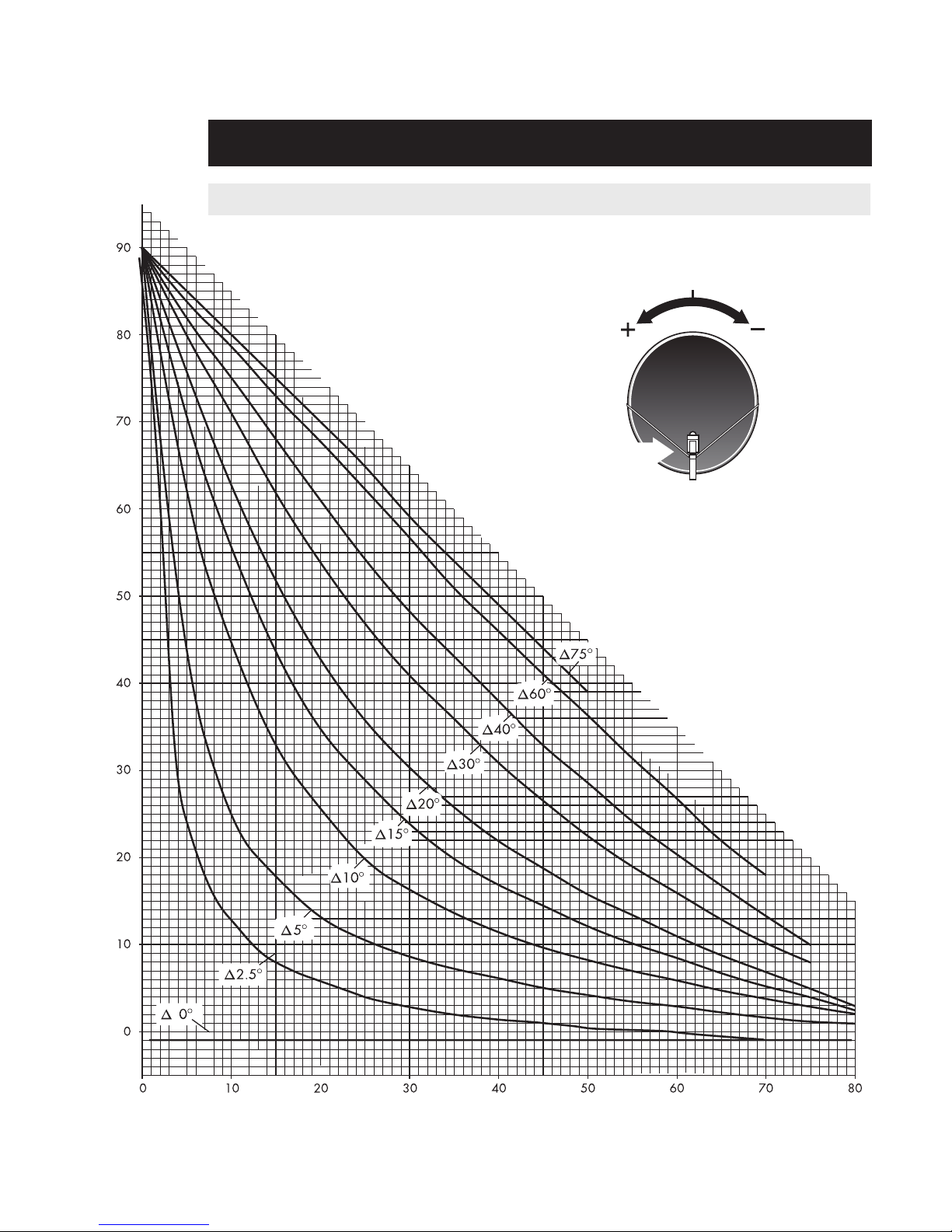

Elevaon Fine Adjustment

1. Make nal adjustments to the elevaon by making slight

adjustments to the 5/16” ange nuts on the threaded

elevaon rod.

2. Adjust the nuts along the length to increase or decrease

the seng to achieve the desired elevaon.

3. Aer the correct elevaon has been established, ghten

the two(2) 5/16” ange nuts located in the arched slots

on the side of the Mount Assembly to 20 Nm (15 – lb)

and ghten the two(2) 5/16” ange nuts on the threaded

elevaon rod using a 1/2" wrench.

Elevaon Coarse Adjustment

1. Slightly loosen the two(2) 5/16” ange nuts located in the

arched slots in the sides of the Mount assembly and the two(2)

5/16” ange nuts on the threaded adjustment rod at the back of

the assembly.

2. Adjust the posion of the 5/16” ange nuts on the threaded

adjustment rod along the length of the rod to adjust the elevaon

angle, moving the nuts up & down to nd the correct posion.

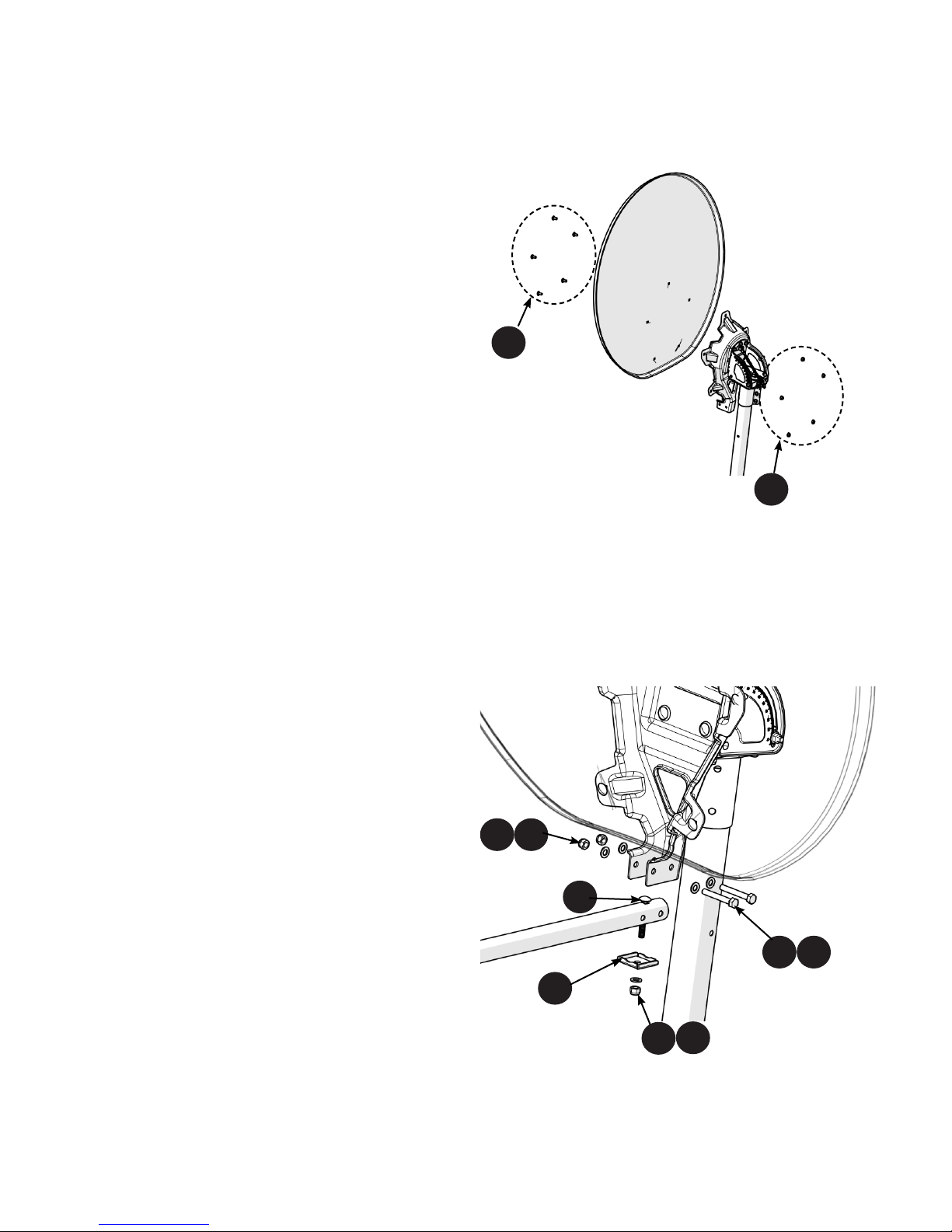

Azimuth Coarse Adjustment

1. Using a compass, set the Antenna in the correct pre-determined

direcon.

2. Secure this posion by fully ghtening the three(3) 5/16”

locking nuts to the canister using a 1/2" wrench.

2.1 ANTENNA ALIGNMENT PROCEDURE

Azimuth Fine Adjustment

1. Slightly loosen the three(3) 5/16” locking nuts mounted to

the underside of the mount assembly.

2. Adjust the azimuth by turning the adjustment screw

clockwise or counter-clockwise unl the desired angle is

achieved.

3. Aer vericaon with a compass and meter, re-lock the

5/16” nuts to 20 Nm (15 – lb) using a 1/2” wrench.

5

5/16” Flange

Nuts

5/16” Locking

Nuts

5/16” Locking Nuts

5/16” Flange Nuts

Azimuth

Adjustment

Screw