2

Electrostatic Sprayer

PRODUCT HIGHLIGHTS:

Fine Atomization

The diameter of the nozzle of the electrostatic

sprayer is relatively thin, and the mist sprayed is

4 times thinner than an conventional sprayer.

User can cover the same square footage while

using a fraction of the solution.

Electrostatic Disinfection

The electrostatic sprayer uses specialized

solution that is combined with air and atomized

by an electrode inside the sprayer. The spray

contains positively charged particles that adhere

to all surfaces and objects. The particles in the

spray are positively charged, so they are able to

cling and coat any surface they’re aimed at.

High Efficiency

The electrostatic spray clings to objects and

doesn’t easily run. The spray will form a film on

a surface and coat all sides of an object; there is

no need to go over the same area twice. This

not only saves on the amount of solution being

used, but also improves the spray efficiency and

rate.

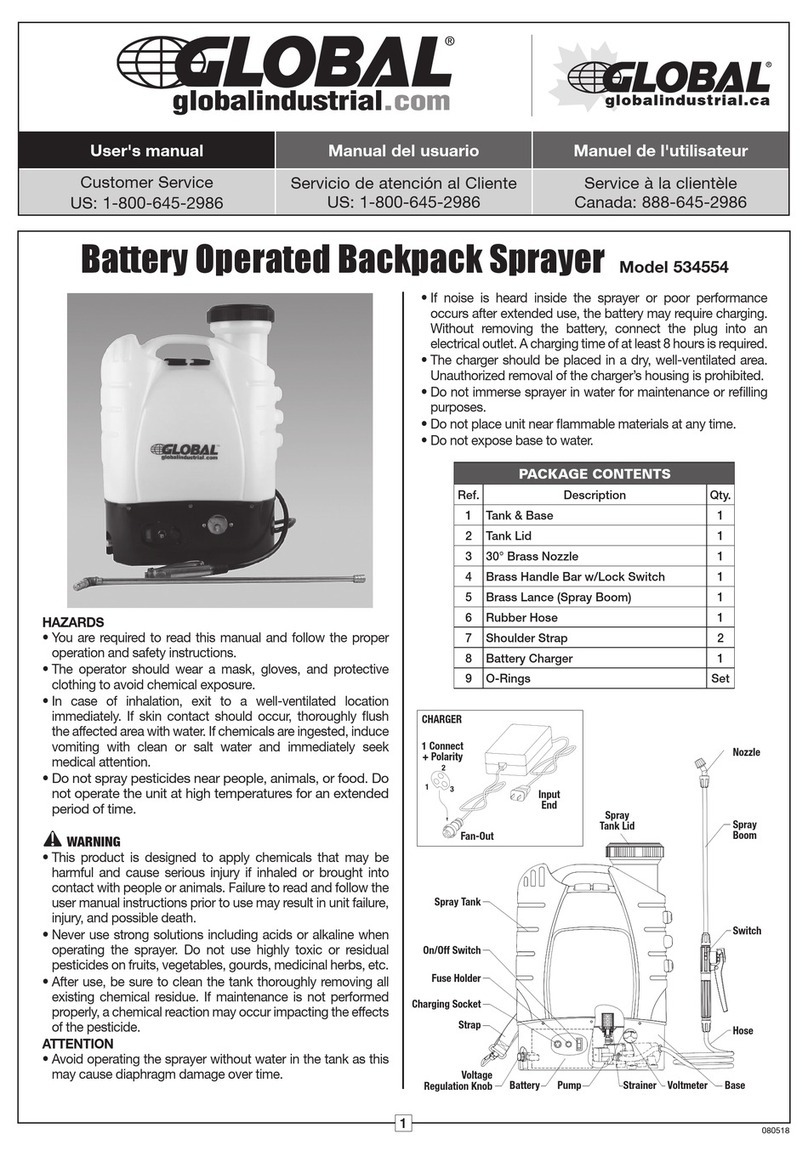

OPERATION:

Installation

1) Insert o-ring and gasket into the groove of the

handle switch port of the sprayer.

2) Connect the wand to the sprayer handle.

3) Select the appropriate nozzle and attach it to

the end of the wand.

Note: Always tighten and inspect nozzles.

Test Sprayer

1) Turn and open the solution tank cap on the

top of the sprayer.

2) Add desired amount of solution into the solu-

tion tank and then close the cap.

WARNING

SAFETY WARNINGS:

Read all the instructions before installation and

operation of this appliance.

To reduce the risk of electrostatic shock,

continuously touch the copper strip on the

handle when the electrostatic switch is

turned on. Use caution when exchanging

hands; ensure one hand is touching the

copper strip at all times.

• To reduce the risk of injury, close supervision

is necessary when used near children.

• DO NOT contact moving parts.

• Only use attachments recommended or sold

by Global Industrial.

• To reduce the risk of electrical shock, do not

immerse electrode in water or other liquid.

• DO NOT touch or insert anything in the nozzle

of the sprayer while device is powered on. After

shutting down, the nozzle should be in contact

with the crop or the ground to eliminate residual

static electricity.

• Use only the battery and charger supplied by

Global Industrial.

• DO NOT let the nozzle touch objects while

spraying.

• DO NOT use static electricity in an environ-

ment with high humidity such as fog or rain.

• NEVER use static electricity during a lightning

storm.

IMPORTANT:

The electrostatic switch is located on the left

side of the base. This switch must be activated

before the power switch on the handle is turned

on. When the electrostatic switch is turned on,

user must touch the copper strip on the handle

at the same time.

Note: The electrostatic sprayer is safe, and will

not cause any harm to the human body.

Note: If the electrostatic needs to be tested, it

is safe to use a common electric pen to check if

the water in the tank is charged.