3

EN

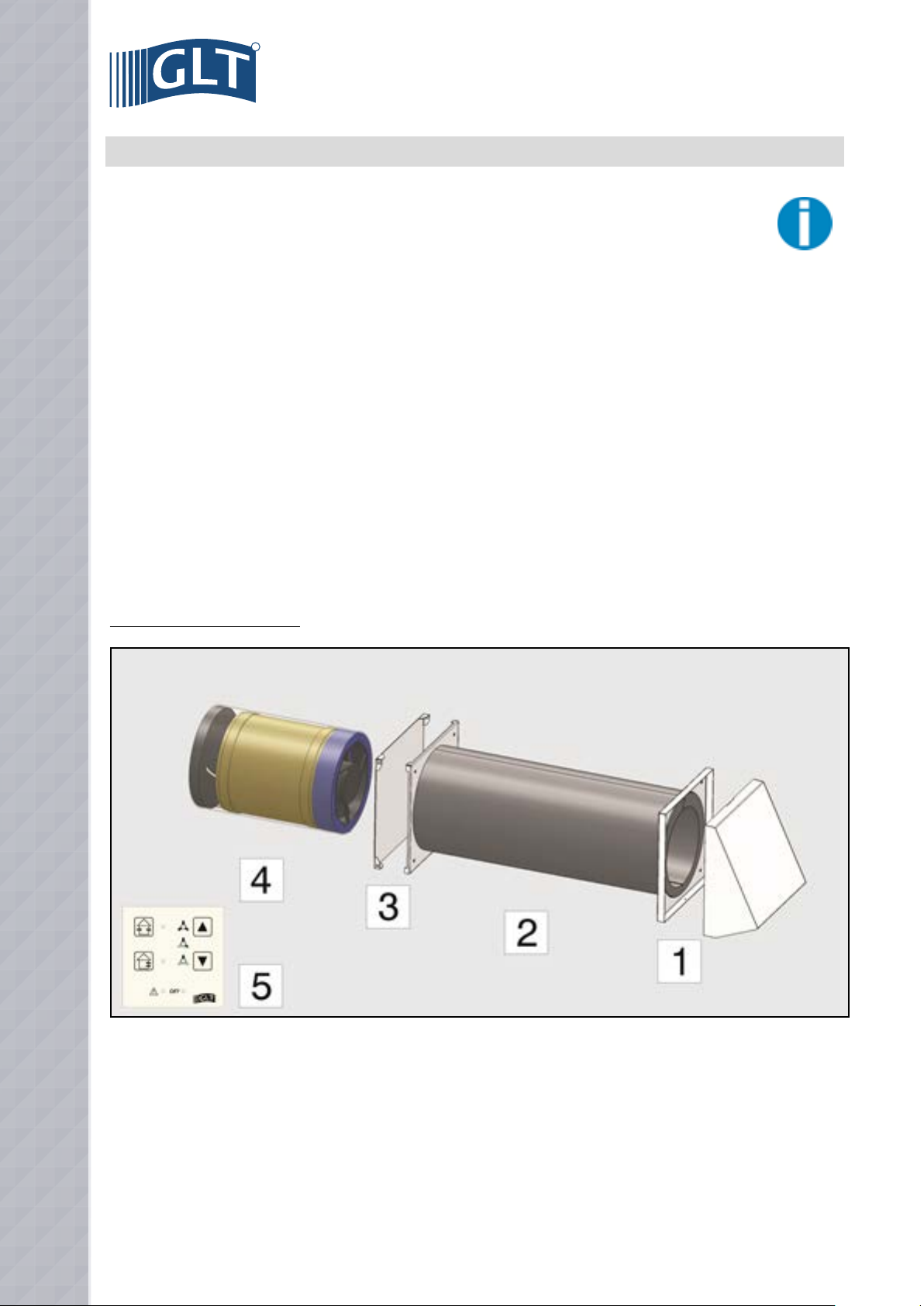

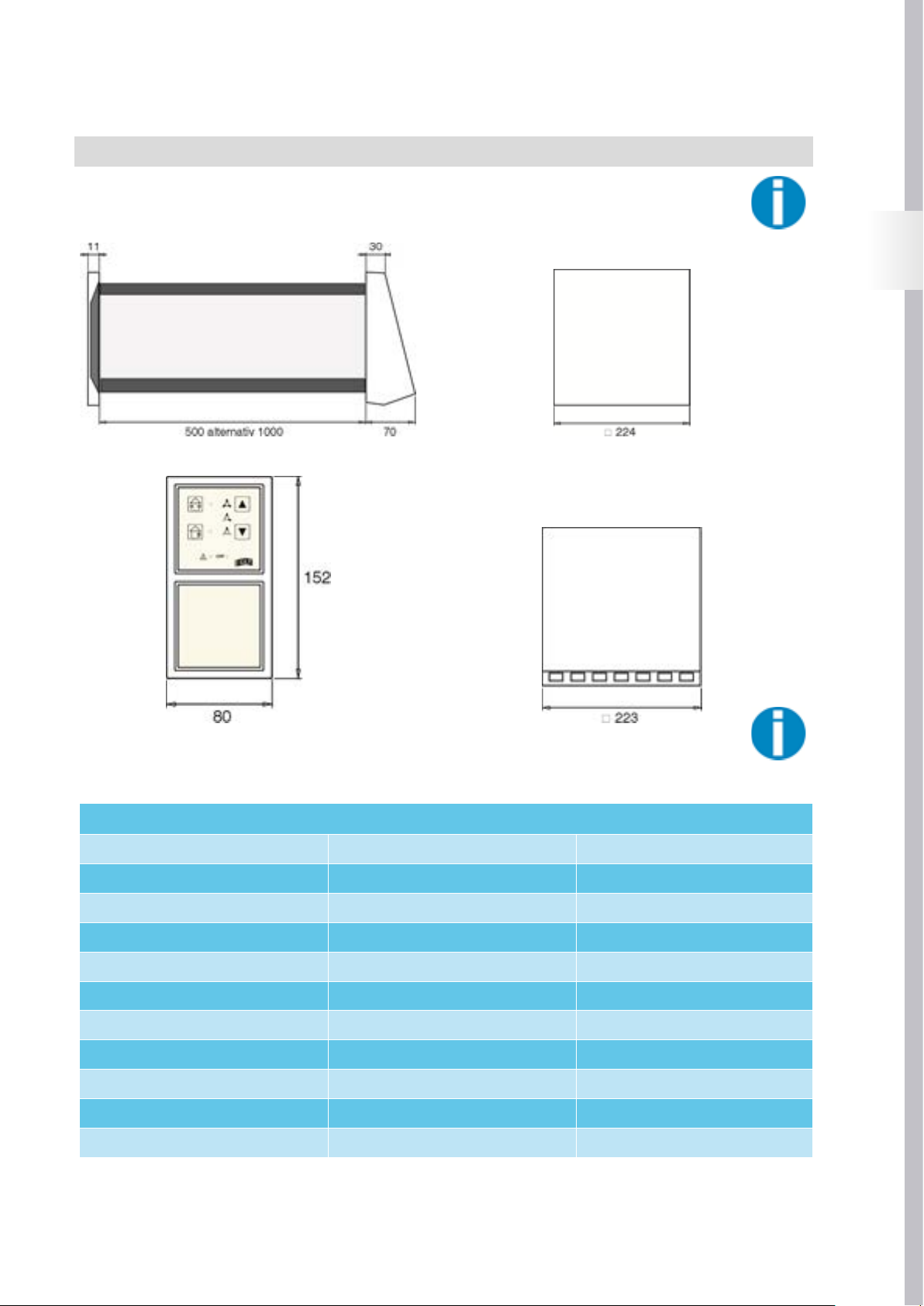

2. PRODUCTINFORMATION

2.1 Modeofoperation

The Fox up ventilation unit is a decentralized ventilation system for a controlled room ventilation with heat recovery. The use

of several units in pairs allows entire housing units / buildings to be ventilated.

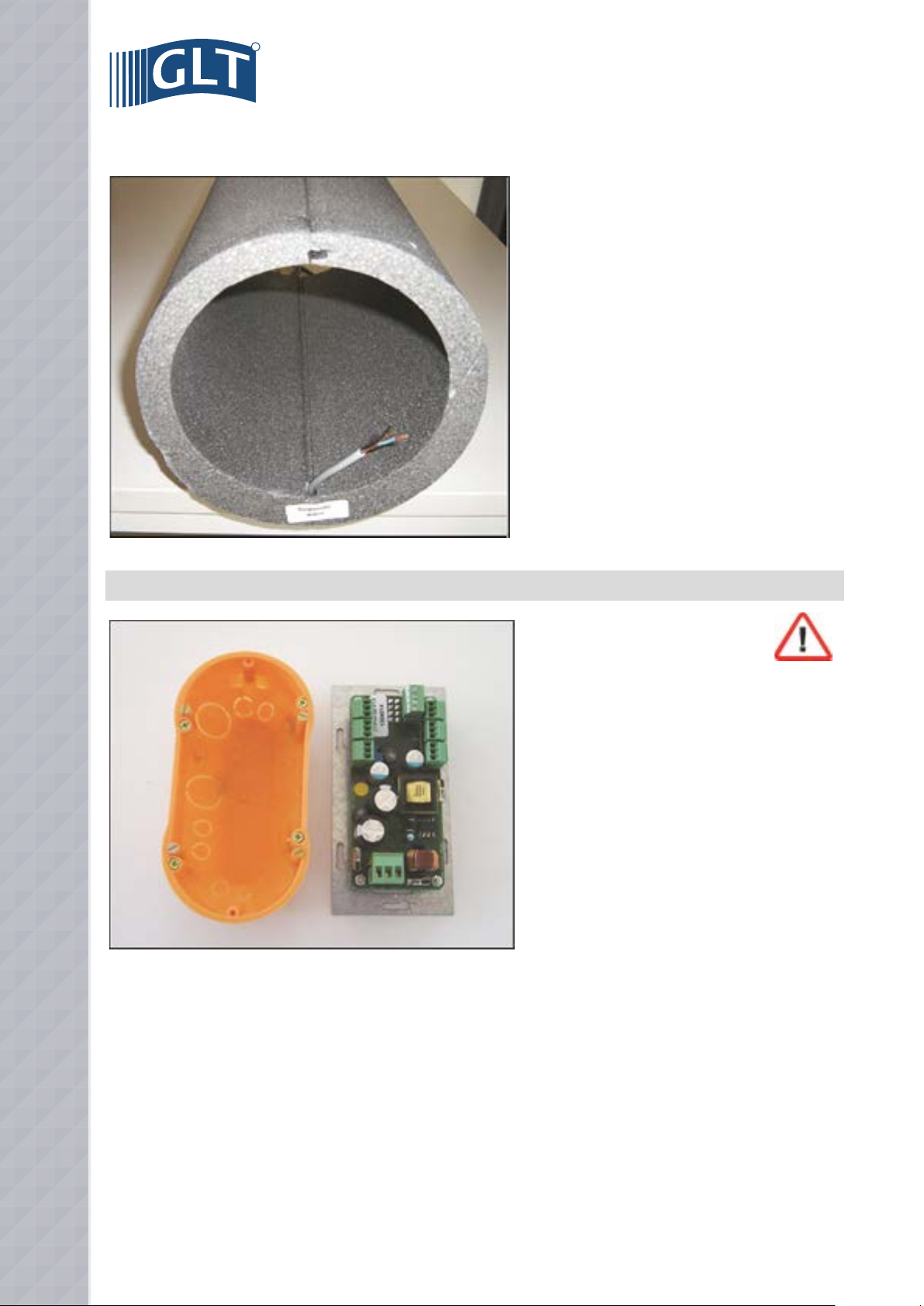

If operated with heat recovery, the ventilation unit works in 2 prefixed time intervals. In the first interval (extraction phase),

the “used” air in the room is sucked into the ventilation unit by the fan and carried to the outside. During this process, the air flows through

the ceramic heat accumulator inside the ventilation unit, which extracts the heat from the air and stores it.

In the second interval (delivery phase), “fresh” outside air is sucked in via the ventilation unit’s exterior opening. It passes through the unit,

and is heated by the heat accumulator before entering the room. In this way, up to 90% of the heat contained in the extracted air can be

transferred to the fresh air fed into the room. The principle of recharging and discharging a heat accumulator is referred as regenerative

heat transfer.

When a single unit is used, an overpressure (delivery phase) or under pressure (extraction phase) is created in the room being ventilated,

this depends on the operating phase. To guarantee a balance between the volumes of air delivered and extracted, it is recommended that

Fox up units be used in pairs. The control of the ventilation units allows up to three pairs of units to be operated simultaneously.

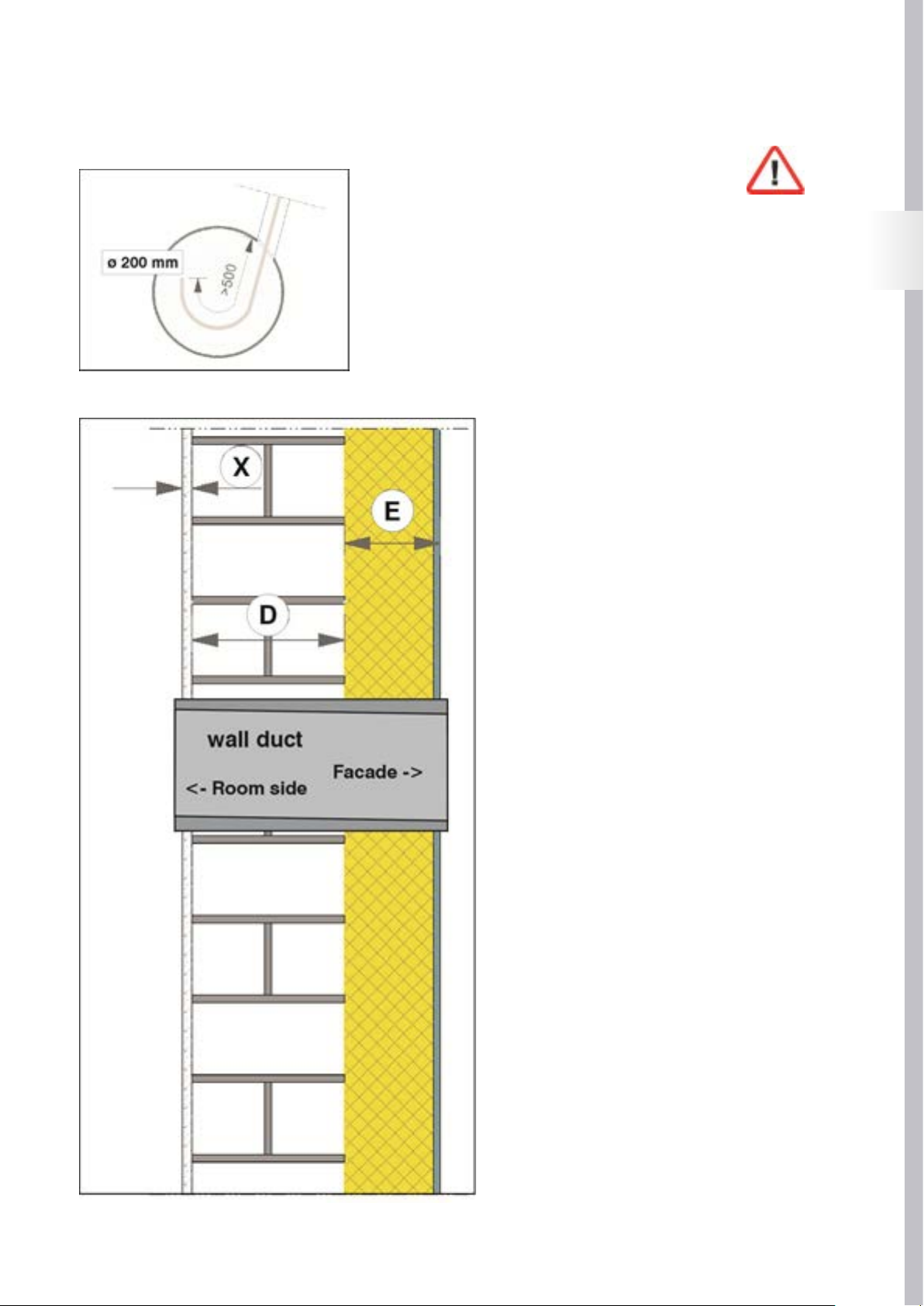

2.2 Planningnotes

Before installing Fox up ventilation units, a ventilation plan should be made. This specifies the number of ventilation units,

their locations, the ventilation principle (transverse ventilation, single-room ventilation). Also it specifies the position and

number of the associated electronic control systems. Fox up ventilation units allow the following variations in ventilation:

• Single-roomventilationwith one ventilation unit, alternating between delivery and extraction modes with heat recovery at intervals,

alternatively delivery* or extraction* mode (* depending on the electrical connection, see page 9).

• Transverseventilationwith ventilation units operating in pairs, alternating between delivery and extraction modes with heat recove-

ry. While one unit of a pair runs in delivery mode, the designated second unit operates in extraction mode. The air direction of both units

swapping in the next interval, alternatively delivery* or extraction* mode (* depending on the electrical connection, see page 9)

.

Where possible, Fox up ventilation units should be used in pairs see Mode of operation. The pairs of units can be used in one or multiple

rooms. It can also be arranged across more than one floor within a unit. The air must be free to flow between the rooms which needs to be

ventilated by means of sufficient dimensioned overflow openings (e.g. door air grilles or shortened door leaves).

To prevent that odors are being transferred to other rooms (delivery phase of ventilation unit), two units operating in a push-pull arrange-

ment should always be installed when airing/ventilating kitchens, bathrooms or toilets with windows.

Fox up units should not be used in internal, windowless exhaust-air rooms such as kitchens, bathrooms and toilets. It is not permissible to

connect the units to a shaft or pipe. In this case, the use of an exhaust fan in accordance with the national norm is recommended, e.g. the

BRAVO fan type.

The units are also unable to be installed in cellar rooms with light shafts, since it is possibility that the outgoing air is recirculated. When

the units are installed on a façade there needs to be a minimum distance of 1.2 m between individual units in order to avoid recirculation.

We recommend not using the unit in a location on the building that is exposed to the wind with a average wind speed of more then 5 m/s.

To prevent the ventilation units from causing inconvenience draughts, they should not be positioned directly next to people who are a

longer time in one place (seating, beds). Make sure that the flow of air into the room is not obstructed by furniture or curtains