v09/2020

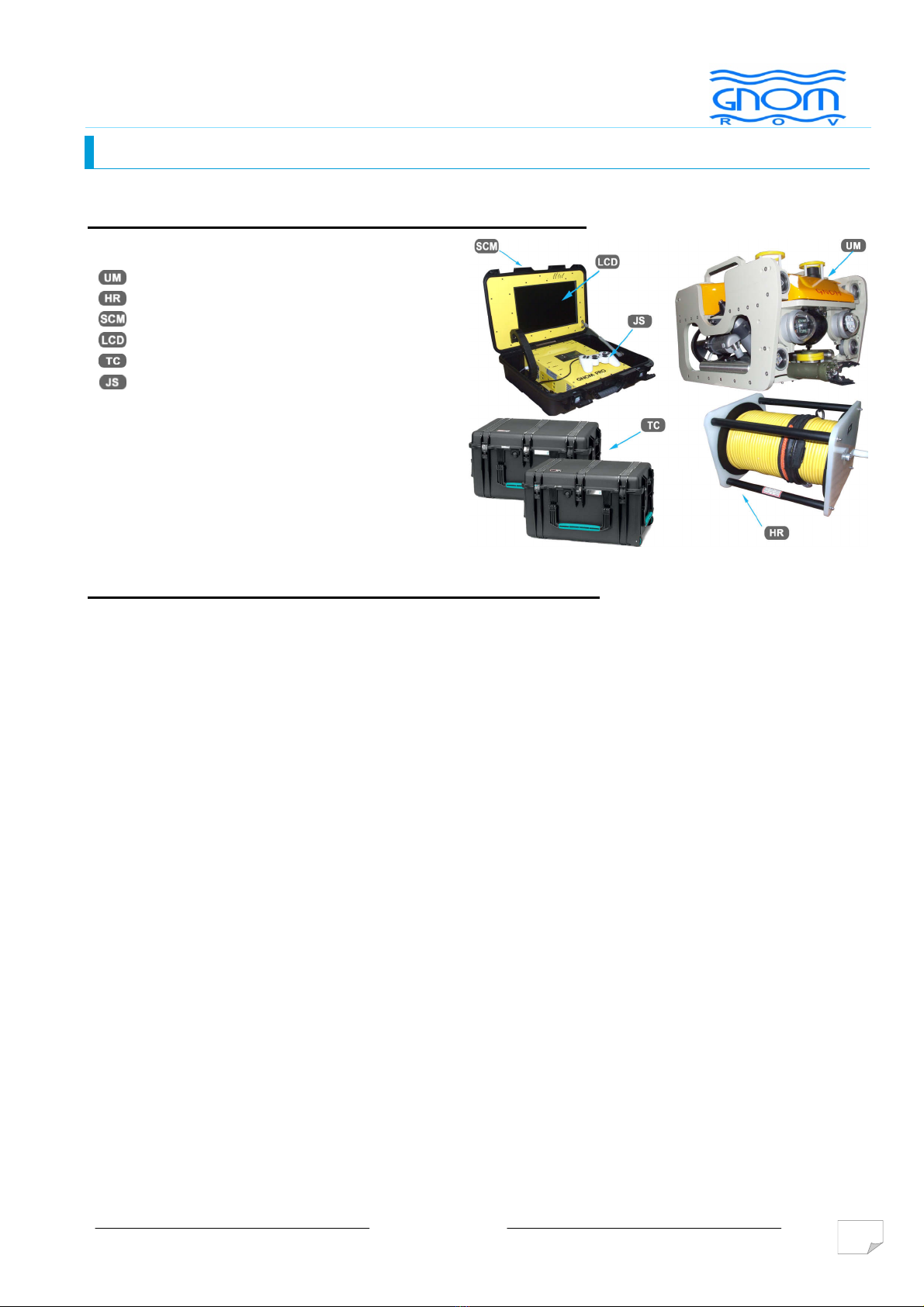

1. DESCRIPTION

The vehicle is connected with the surface unit via thin cable transmitting power voltage, operation

instructions, data, and video signal from the vehicle.

The cable with diameter 6mm is strengthened by Kevlar threads (breaking effort is 200kg) and by

additional polyethylene shield. The maximum cable length is up to 400m. To counerbalance the weight

of the vehicle and give it a neutral buoyancy, the foam polystyrene float is installed in the front part of

the vehicle. Similar floats can be put on the cable to change the neutral buoyancy to a little positive.

Maximal operating depth of the vehicle is 150m.

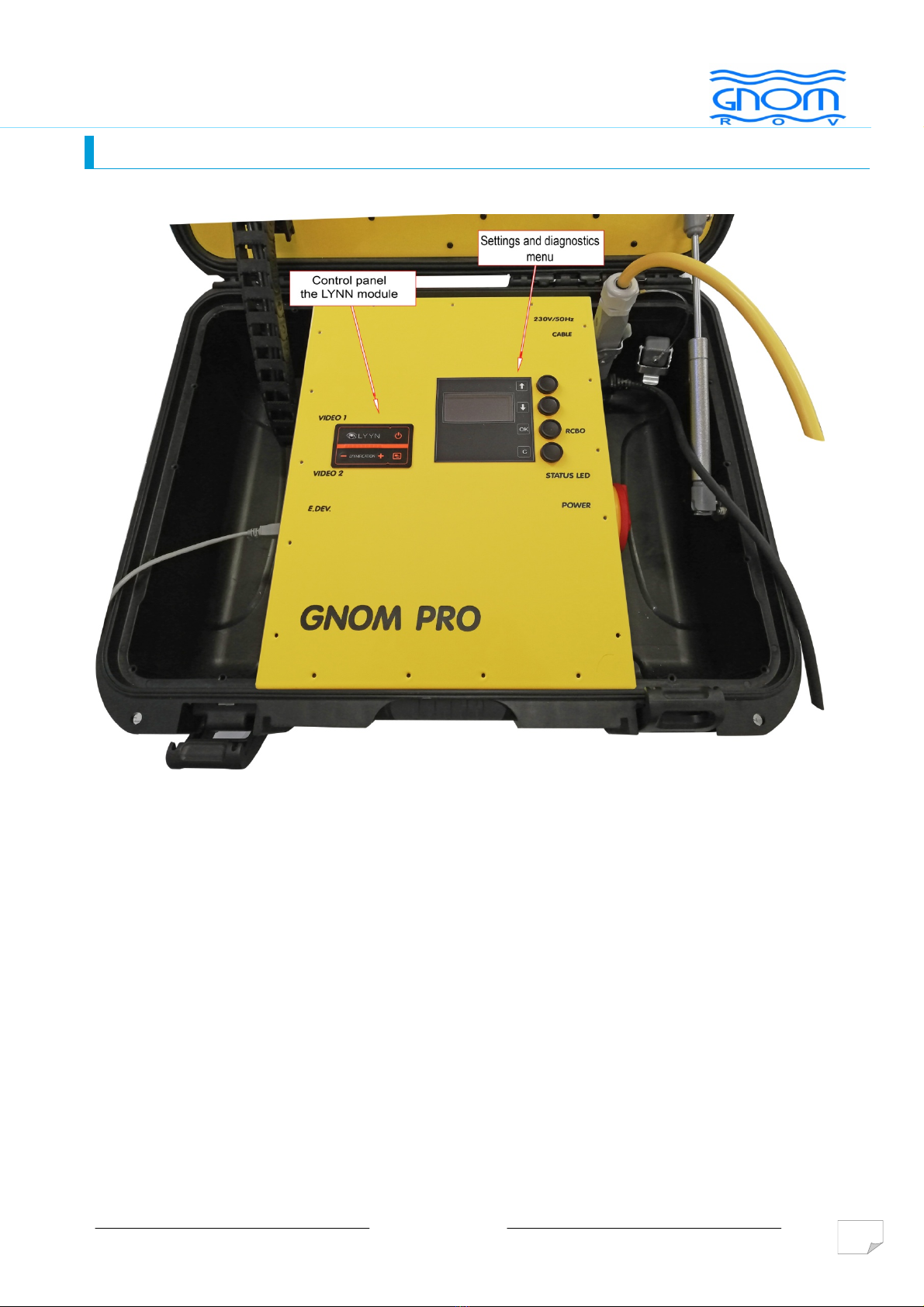

Using the control pads and joystick, the operator can move GNOM forward and backward, turn to the

right and left, up and down; adjust the thruster speed and the brightness of the lights. All data is

displayed on the monitor in the "TV-text" mode. By pressing one of the buttons on the joystick, the

operator can enter the menu to tune up some of the functions – calibrate the depth sensor and the

compass, as well as some other functions.

1.2

TECHNICAL SPECIFICATION

Speed:

horizontal motion, up to 1,5 m/s

vertical motion, up to 0.5 m/s

lateral motion, up to 0.5 m/s

(above numbers depend on a length of the cable)

Max operating depth 150 m

Power voltage 100-230VAC 2000 Watts

Operating temperature range from -5 to +45°C

Operating environment humidity up to 100%

Weight of the vehicle 25 kg

Full weight of the system 100 kg

Dimensions of vehicle (WxLxH) 440х650х360 mm

Tether:

diameter 11 mm

length up to 400 m