GRINDER STRAIGHT HANDLE GH-10-28-O OPERATION MANUAL

4

1About this manual.............................................................................................................................................. 6

2General............................................................................................................................................................... 7

2.1 General information .............................................................................................................................................................7

2.2 Designated use .....................................................................................................................................................................8

2.3 Environment requirements...................................................................................................................................................8

2.3.1 Operating requirements .......................................................................................................... 8

2.3.2 Emissions ................................................................................................................................. 8

3Safety ................................................................................................................................................................. 9

3.1 Basics ....................................................................................................................................................................................9

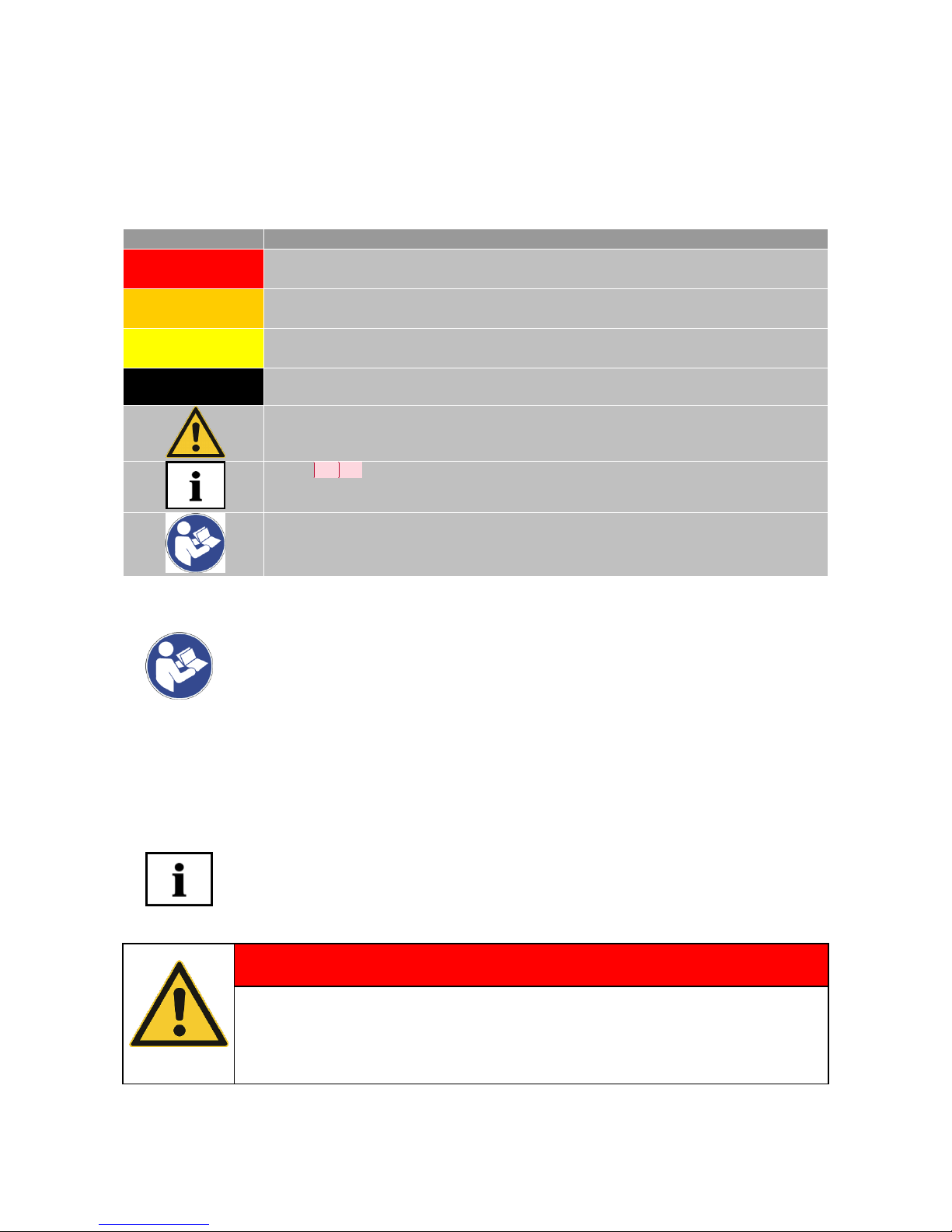

Table 1: Signal words and symbols .................................................................................................. 10

3.2 Important safety information .............................................................................................................................................10

3.3 Danger zone........................................................................................................................................................................13

3.4 Qualification of the operating and maintenance personnel ...............................................................................................13

3.5 Emergency information / safety devices ............................................................................................................................14

3.6 Safety signs .........................................................................................................................................................................14

Table 2: Safety signs......................................................................................................................... 14

4Design and function...........................................................................................................................................15

4.1 Design .................................................................................................................................................................................15

4.2 Specifications ......................................................................................................................................................................15

Table 3: Specifications...................................................................................................................... 15

4.2.1 Hydraulic fluid........................................................................................................................ 16

Table 4: Hydraulic fluids................................................................................................................... 16

Table 5: Suitable hydraulic fluids ..................................................................................................... 16

4.2.2 Supply, interfaces and connections....................................................................................... 16

4.3 Function ..............................................................................................................................................................................16

4.4 Boundaries and interfaces ..................................................................................................................................................16

5Transport, assembly and dismantling ................................................................................................................17

5.1 Mounting the grinding stone ..............................................................................................................................................17

6Commissioning and operation ...........................................................................................................................19

6.1 General information for start-up ........................................................................................................................................19

6.2 Specification of the hydraulic system .................................................................................................................................19

6.2.1 Function test .......................................................................................................................... 19