6.4.1

Bacteria

Filler

Repiacement:

1.Unscrewthe

filter

fromthevacuumand

filter

connection(See

Illustration

No.

1 orNo.2)byhandturningina

counter-cloci<wise

direction.

2.

Screwa new

filter

into

thevacuumand

filter

connectionbyturningina

clockwise

directionfinger

tight.

Note:

Care

mustbetakenwhenreplacingthe

filter

topreventthread

damageduetocrossthreadingandovertightening.

6,5GlassCollection

Bottle

andCapAssembly

Steriiization:

1.Removethecapassemblyfromthebottle.

2.

Disposeofdrainagefluidsandmaterialsinthebottle.

3.

Soak

the

bottle

andcapassemblyina warmdetergentsolution.Washallthe

parts

with

a nylonbristlebrush,rinsethoroughly

with

waterandaerate.

4.

Autoclaveat250°F for15minutesfollowingtheautoclavemanufacturer'srecom-

mendedprocedure.

Caution:

Donotflashautoclavetheglasscollectionbottle.Ifdesired,sterilize

with

ethyleneoxidegas.Followmanufacturer'sdirectionforrecommendedprocedure.

6.6

Control

Circuit:

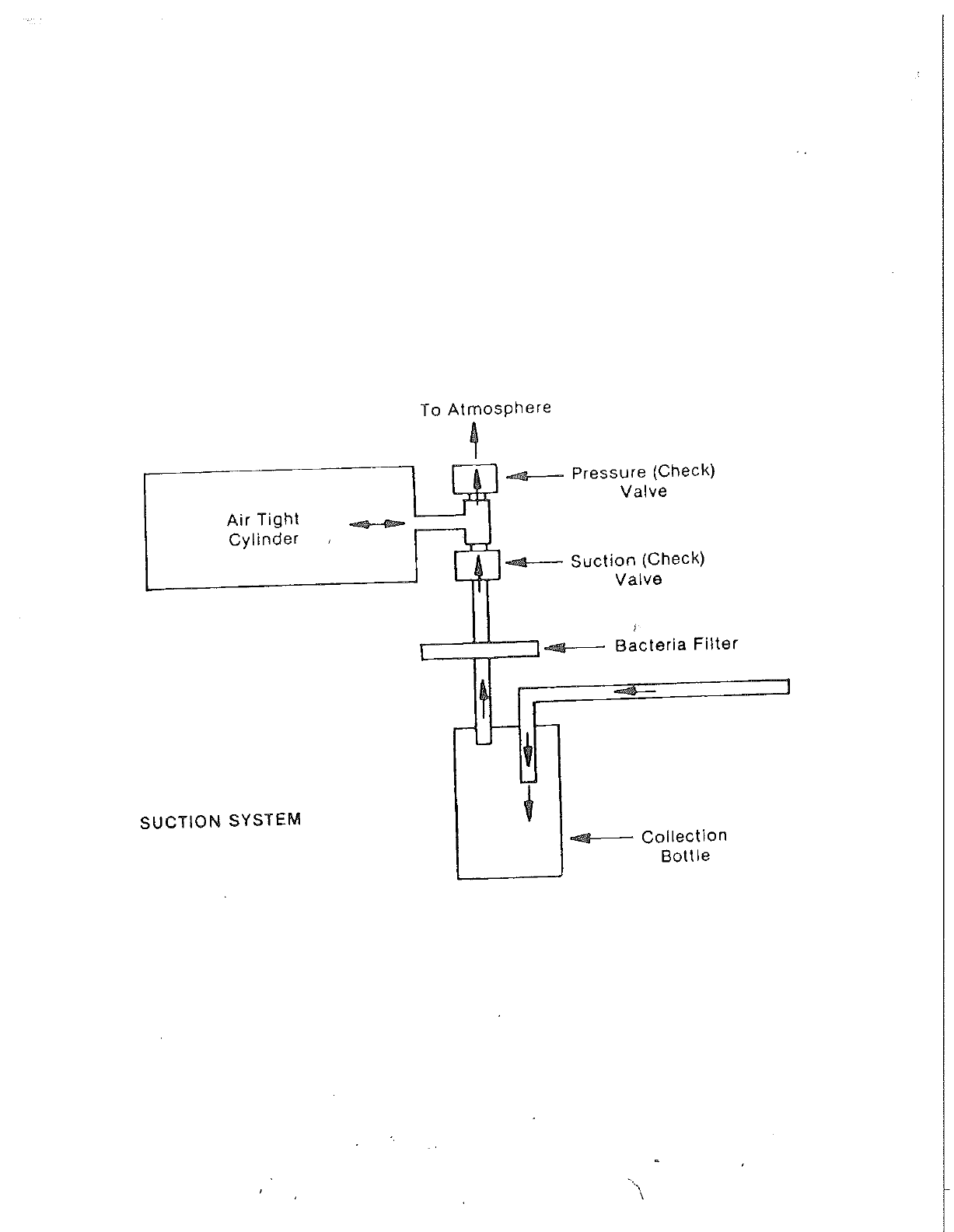

Thepumpcyclesarecontrolledbya solidstateprintedcircuitboard(See

Illustration

No.7)

Shts.

1

thru

5 forschematicandparts

list)

orTimer(See

Illustration

No,7A).

Thetimingisfactorysetandneedsnoadjustment.

Control

Circuit

Description

(PN-2311)

Illustration

No.7

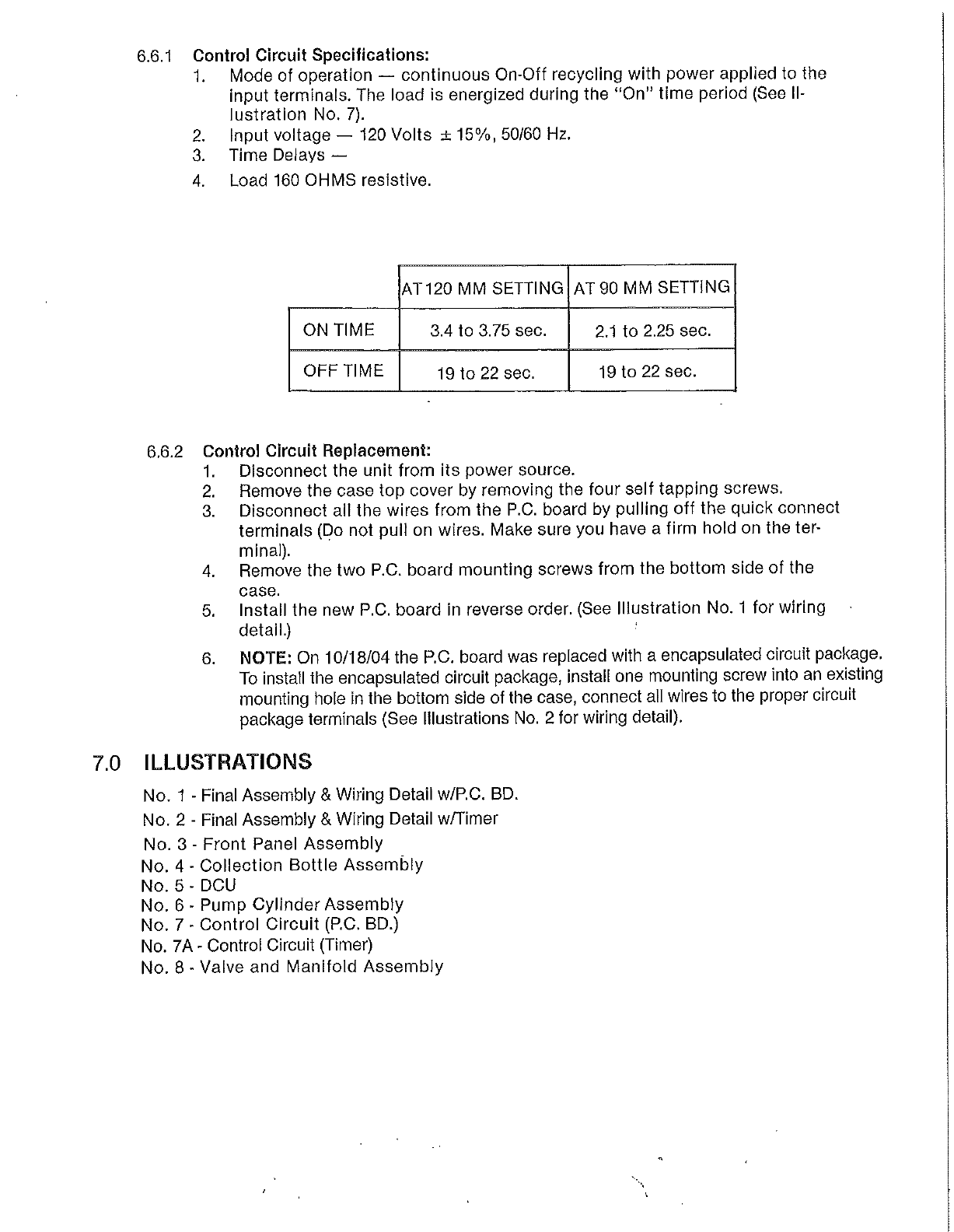

TheSF120A-774isanOn/Offrecyclingtimerwhichprovidesa fixed"Off"timeof19to22

seconds

anda selectable"On"timeofeither3.4to3.75secondsor2.1to2.25

seconds.

The2.1to2.25second"On"timecanbeselectedbyshortingterminals4 and5 together.

Whenpowerisapplied,the"On"timeoccurs

first.

A

9Vpowersupplyissuppliedby

Dl,

Rl,

C6,C7,

08,

and

Zl.

07

and

08

areusedforhigh

frequencynoisefiltering.C6isthe

filter

capacitorfortheVz wavevoltagesupplied

throughD1,and

Rl.

Zl

istheregulatingzenerdiode.

Thecircuittimingisaccomplishedbyusinga MC14541programmabletimer,IC1.ThisIC

has

a

built

inoscillatorchipwhosetimingcomponentsareconnectedbetweenpins1,2,

and3.Thepin3 connectionusedisdeterminedby

102,

a

MC4016

bilateralswitch.The

sec-

tionsofthisswitch

that

areturnedon,determinethetimingcomponentswhichare

used.

Duringthe"Off"timeinterval,P3,R7,

Rll,

and

02

comprisethetimingcomponents.

These

areselectedbya highsignalonpin6 of

102.

Thelonger"On"timetimingcomponentsareP2,R6,

R12,

andC3.Theseareselectedbya

highsignalonpin12of

102,

Whena shorter"On"timeisdesired,P2,andR6areparallel

byP1andR5byapplyinga highsignalonpin13of

102.

Since

"On"timeisrelativelyshort,

resistorR14,a zeroOHMresistor,isconnectedbetweenpin5 ofIC2andcommonduring

test.Thispreventsthetimerfromgoing

into

the"Off"time

until

both"On"timeshave

been

calibrated.Thisresistoristhenremoved.

The

output

ofthetimer

Is

connectedthrougha

full

wavebridge,BR1,andSCR.

01.

The

gatedivetotheSCRiscontrolledby

R2.

Q2,R4,andpin8 of

ICI.

Whenpin8 islow,tran-

sistorQ2isoff.andgatecurrentto

Ql

issuppliedto

01

viaR2.ThetimeristhenInthe

"On"

state.Whenpin8 of

101

ishigh,transistor

Q2

Is

"On",shortingthegatecurrentof

Ql

tocommon.Thisprovidesthe"Off"

time.

IC1isprogrammedbytheconnectionofpin12and13eithera highorlowstate.Forthis

circuittheICisprogrammedtodividetheoscillatorfrequencyby1024.

Since

theQ

output

of1C1willchangestateinonehalfof

that

numberofcounts,thenumberof512isusedto

calculatetheoscillatorfrequency.Therefore,theoscillatorfrequencymeasuredatpin1 of

ICI

shouldbe24.98Hzforthe"Off"time,143.22Hzforthelong"On"

time,

and227.56Hz

for

theshort"On"time.