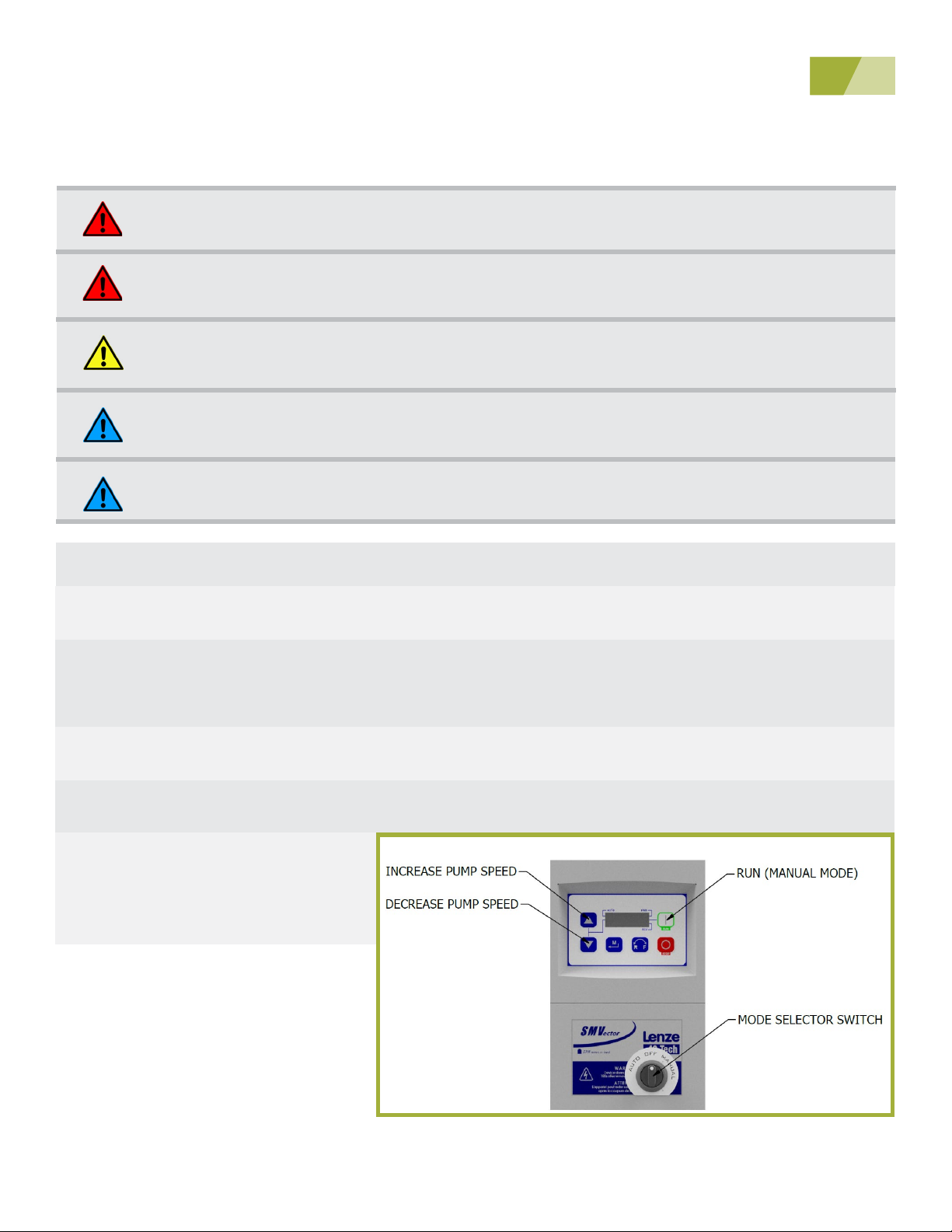

420 SECTION 1: SAFETY PRECAUTIONS

DANGER: This machine is not intended for use by persons (including children) with reduced physical,

sensory, or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the machine by a person responsible for their safety.

DANGER: Never place hands, arms, or any foreign items into the pump housing during operation. Personal injury

including lacerations and amputations, or damage to the machine can occur.

WARNING: Power must be supplied to the Pump Cart by a licensed electrician. Failure to do so may result in

serious personal injury due to electric shock or damage to the machine.

WARNING: Disconnect all power before performing maintenance to avoid risk of serious electric shock.

WARNING: Always check with your local health department regarding procedures required to ensure proper

cleaning and sanitation in order to avoid serious foodborne illness to consumers. For the US: FDA.gov/food

WARNING: Discontinue use immediately and have machine serviced if any components are damaged or

malfunctioning to avoid risk of personal injury and damage to the machine.

WARNING: Be aware of all pinch points and moving parts and take precautions to keep loose clothing, hair, or

foreign objects away from them to avoid personal injury and damage to the machine.

WARNING: Disconnect all power before moving machine. Avoid damaging the power supply cord during

movement and use cautionary steps to avoid tipping.

WARNING: Electrical and mechanical repairs are not to be carried out by the operator unless authorized to do so.

WARNING: Operator should not use unauthorized means of gaining access to parts of the machine which are not

normally accessible.

WARNING: Operator should ensure plug is visible from points of access.

WARNING: Operator should ensure the surrounding area is free of debris and slipping hazards to prevent injury.

WARNING: In the event of an accident or breakdown, all power supply should be disconnected from source and

Goodnature customer service should be contacted for support.