3

Table of contents

Introduction ················································································· 1

Table of contents ··········································································· 3

1.Safety Precautions ······································································ 4

1-1 Basic safety precautions ························································· 4

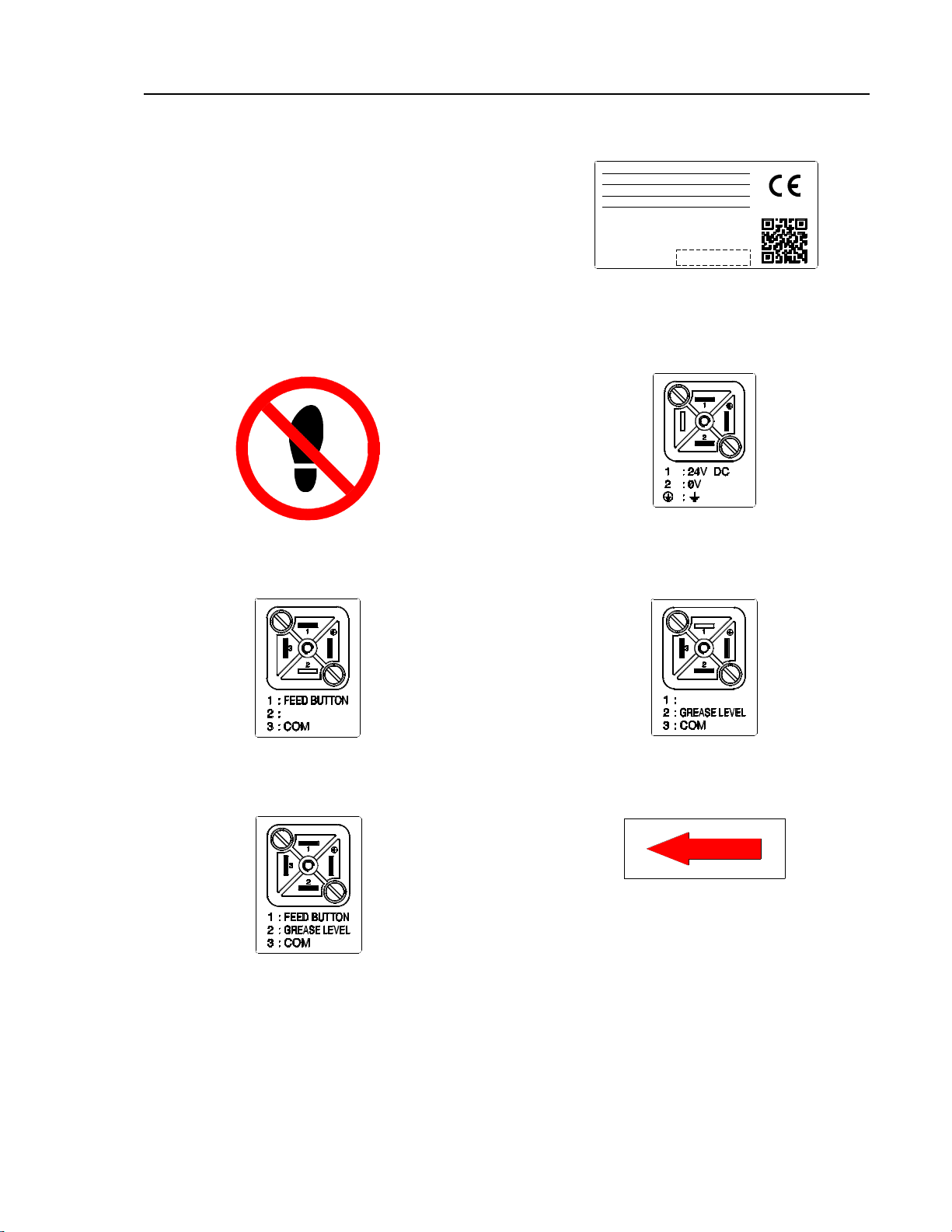

1-2 Labels················································································· 5

1-2-1 Type of labels ··································································· 5

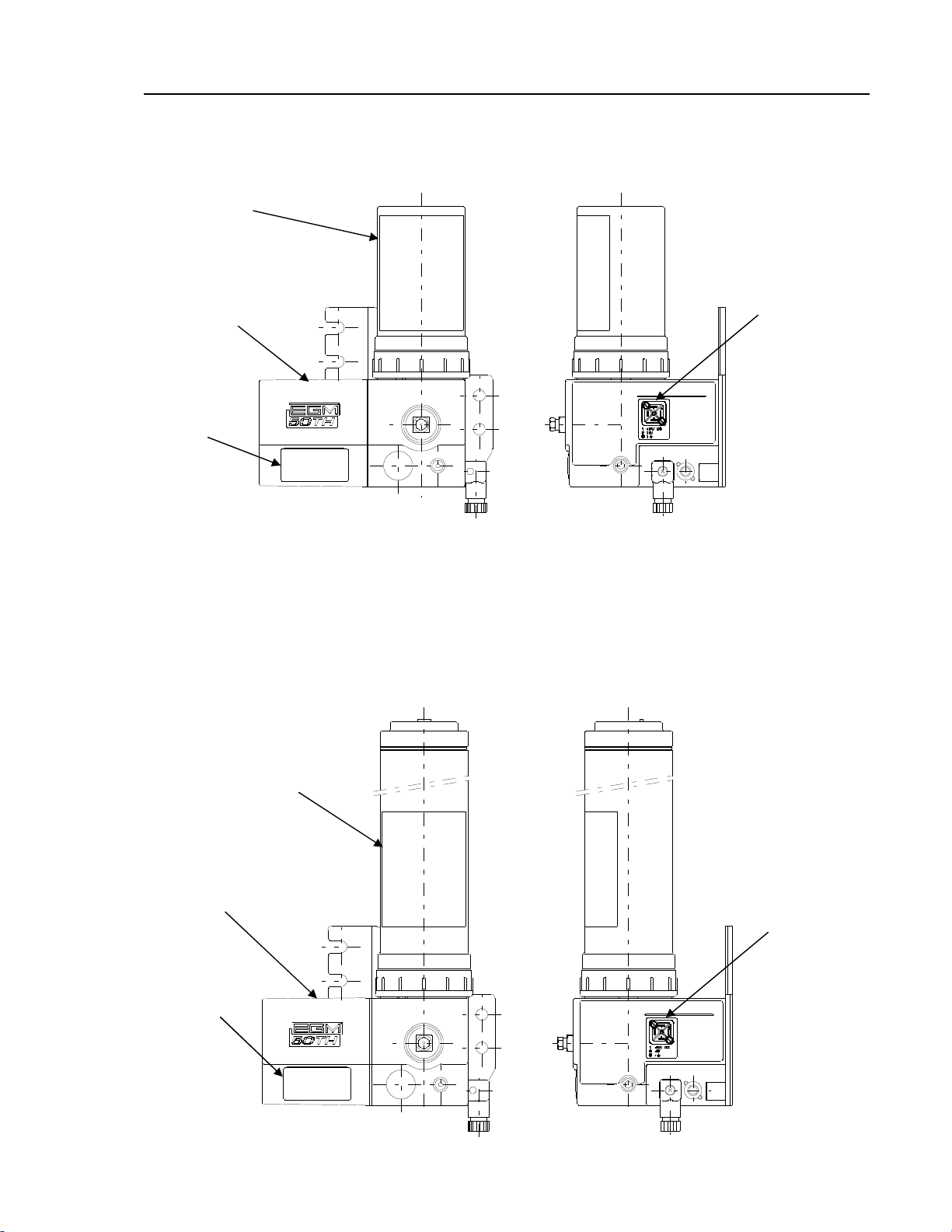

1-2-2 Location of labels ······························································ 5

2.Specification and Outline ····························································· 7

2-1 Specification ······································································ 10

2-2 Name of each component ······················································ 11

2-3 Repair parts ······································································ 14

3.Installation ············································································· 15

3-1 Environmental requirement ················································· 15

3-2 Mounting unit ···································································· 15

3-3 Wiring ·············································································· 17

3-3-1 DIN connector wiring diagram ·········································· 18

3-3-2 DIN connector connection procedure ·································· 19

3-4 Tubing ·············································································· 21

4.Setting of Timer on Machine ······················································· 22

5.Refilling Grease ······································································· 23

5-1 Grease ·············································································· 23

5-2 Replacement of grease cartridge (for the cartridge type only) ······ 23

5-3 Grease replenishment method (for the tank type only) ··············· 25

6.Maintenance ············································································ 26

6-1 Bleeding ············································································ 26

6-2 Replacement of repair parts ·················································· 27

6-2-1 Replacement of pumping unit ··········································· 27

6-2-2 Replacement of relief unit ················································ 28

6-2-3 Replacement of filter ······················································· 29

6-3 Troubleshooting ································································· 32

Appendix. Grease contamination: Causes and measures ····················· 35