4. Inspect impeller (Ref.

No. 26). If clog is found,

remove debris and

reassemble in reverse

order. If damage to

impeller is found, such as

pitting, deep grooves, or

breakage, proceed to

next section.

IMPELLER REPLACEMENT

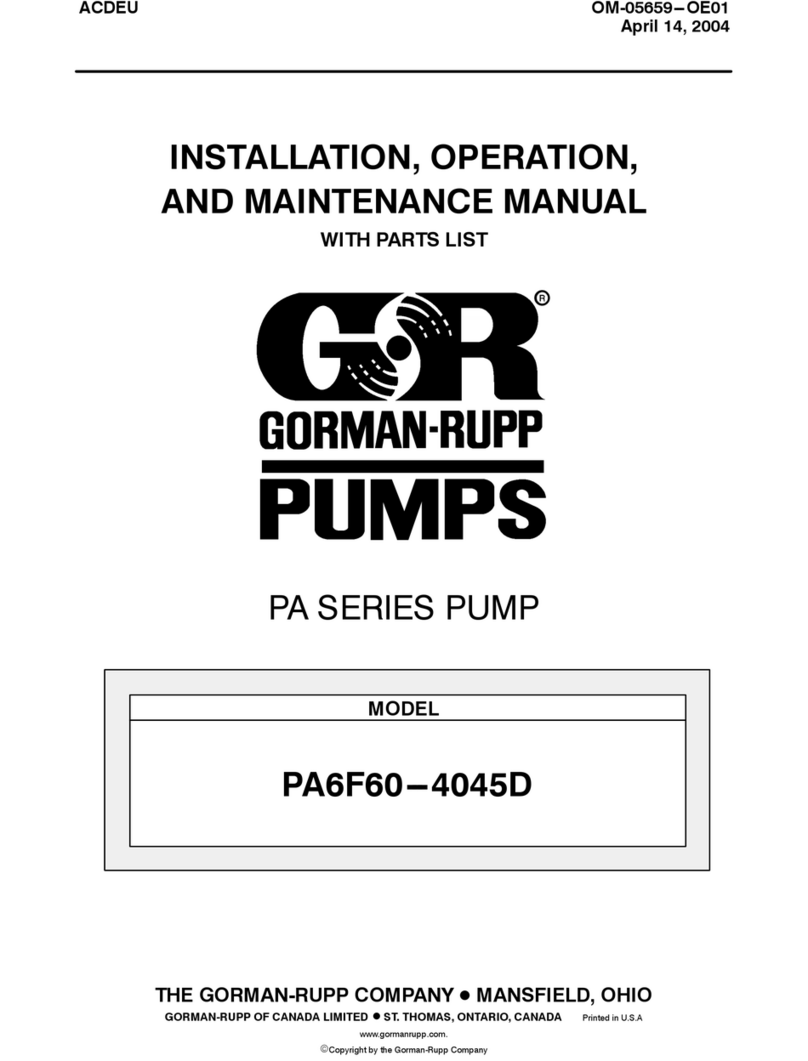

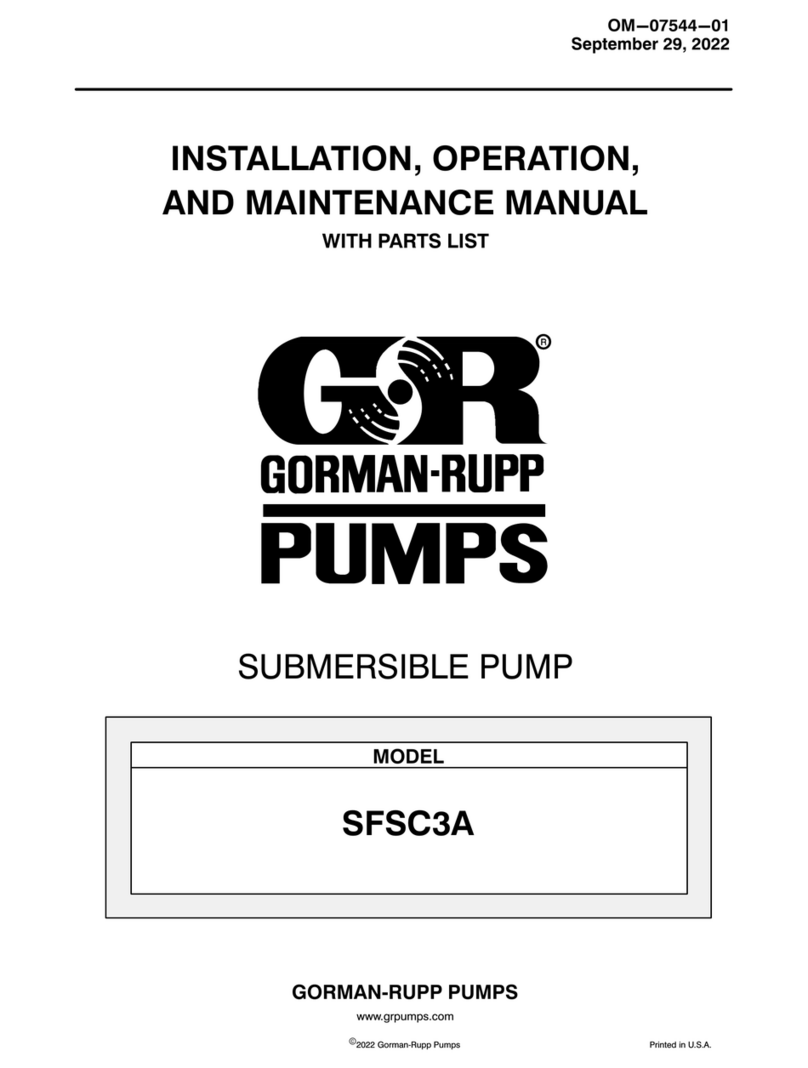

5. Remove impeller fastener

(Ref. No. 28) by unscrew-

ing in counterclockwise

direction.

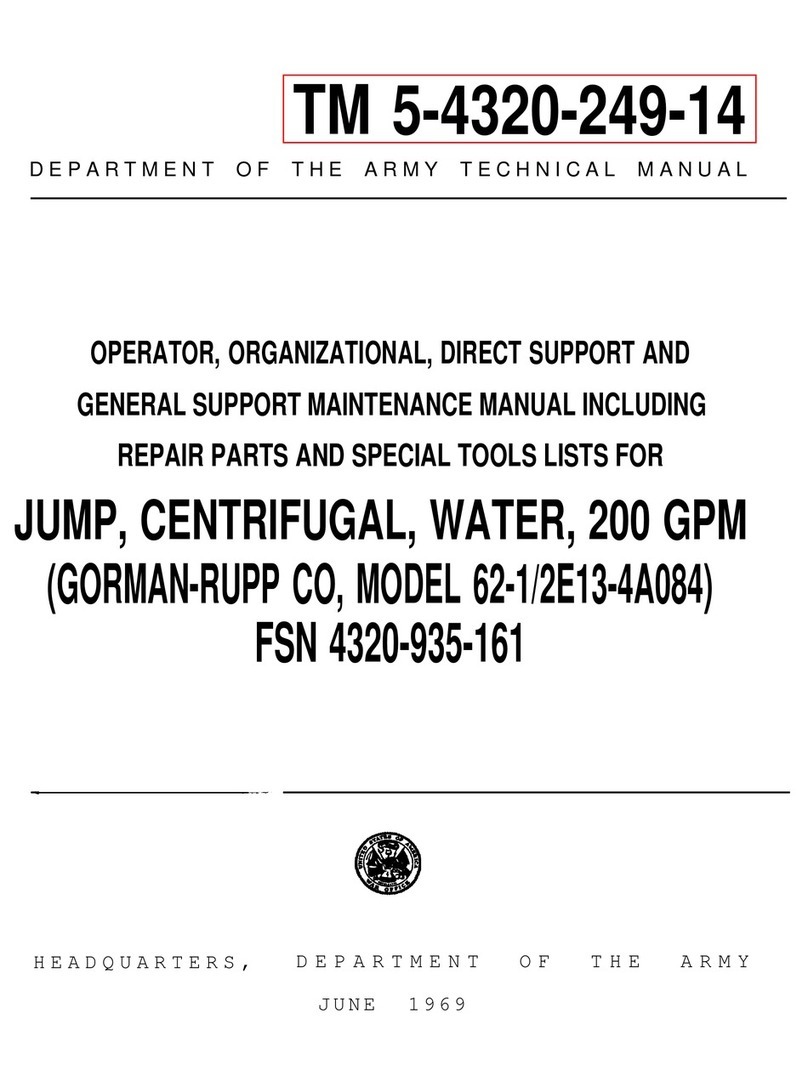

NOTE: To prevent motor

shaft from turning, wedge a

screwdriver between impeller

vane and impeller fastener

(see Figure 2).

6. Slide off impeller washer

(Ref. No. 27). Impeller is

keyed to motor shaft and

can now be pulled free.

7. Install replacement

impeller and reassemble

in reverse order.

MECHANICAL SEAL

REPLACEMENT

Motor internals are protect-

ed from contact with liquid

being pumped by a mechani-

cal shaft seal and oil cavity.

When seal wears out, poten-

tial motor life will be com-

promised. Therefore, periodic

seal replacement is recom-

mended. Time interval

between replacements will

depend on abrasiveness of

liquid being pumped, tem-

perature, total accumulated

runtime, etc.

IMPORTANT: Always replace

seal head (Ref. No. 18) and

both seal seats (Ref. Nos. 17

&19) at same time to insure

proper mating of compo-

nents.

Refer to Figure 3.

1. Disassemble pump by fol-

lowing directions in both

“Power Cord

Replacement” and

“Impeller Inspection /

Replacement” sections.

2. With unit on its side and

wire cover, pump assem-

bly, and impeller

removed, lift shaft key

(Ref. No. 13) from

shaft/rotor (Ref. No. 12)

using a pliers.

3. Clean rust and buildup

from unit.

4. From top of unit, remove

four long fasteners (Ref.

No. 10) which attach

lower end bell (Ref.

No. 16) to motor case

(Ref. No. 11).

5. Rap on ears of lower end

bell with a soft mallet to

break it free from motor

case. Then carefully guide

lower end bell along with

shaft/rotor and bearing

assembly out of motor

case.

6. Drain oil from seal cavity

by removing drain screw

(Ref. No. 23) and seal

(Ref. no. 22) from seal

plate (Ref. No. 21). Then

tip components upright

overtop of a catch pan

until oil is drained.

7. Remove three fasteners

(Ref. No. 25) and pry out

seal plate with screwdriv-

er. Slinger washer (Ref.

No. 24) will come free at

this time.

8. Use a press or gear puller

to remove shaft and

bearings from lower end

bell. Shaft seal head will

now be free.

IMPORTANT: Shaft seal head

(with spring) has unique

ends, and two seal seats are

different from one another

also. Be sure to note size and

color of each before disas-

sembly so that new parts are

installed in proper orienta-

tion.

9. Remove upper seal seat

(Ref. No. 17) from lower

end bell by using a screw-

driver or dowel to press

on seal from rear. Do the

same for lower seal seat

Specifications Information and Repair Parts Manual

Models 5760-95 thru 576E

3

Figure 2 - Impeller Removal

(Ref. No. 19) in seal plate.

10. Clean seal seat cavities

before inserting new

seals.

11. Carefully wipe polished

surface of new seal seats

with a clean cloth.

12. Wet outside of rubber

portion of seal seats with

alight coating of soapy

water.

13. Press each new seal seat

squarely into cavity in

both seal plate and lower

end bell. If seal seat does

not press squarely into

cavity, it can be adjusted

into place by pushing on

it carefully with a piece

of pipe or dowel. Always

use a piece of cardboard

between pipe and seal

seat to avoid scratching

seal seat. (This is a lapped

surface and must be han-

dled very carefully.)

(continued on page 8)

Screwdriver

Impeller

vane

Ratchet

Wrench