2 308219

Table of Contents

Symbols 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warnings 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure Relief Procedure 6. . . . . . . . . . . . . . . . . . .

Startup Check List 6. . . . . . . . . . . . . . . . . . . . . . . . . .

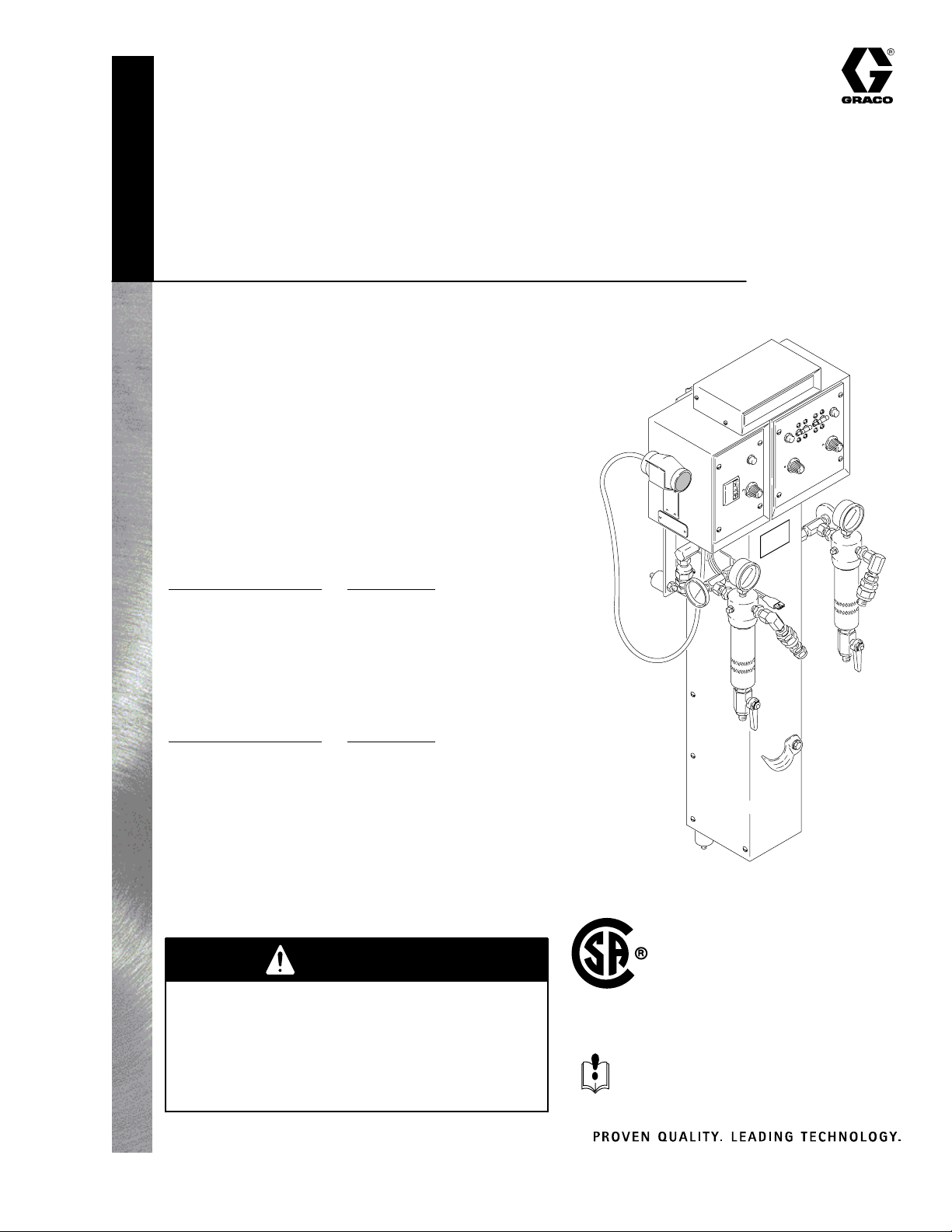

Typical Installation 7. . . . . . . . . . . . . . . . . . . . . . . . . .

Component Description 8. . . . . . . . . . . . . . . . . . . . . .

How to Size a Generator 10. . . . . . . . . . . . . . . . . . . .

Mount the Heater 10. . . . . . . . . . . . . . . . . . . . . . . . . .

Flush the Heater 11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Connect the Electrical Service 12. . . . . . . . . . . . . . .

Ground the System 13. . . . . . . . . . . . . . . . . . . . . . . .

Prime the Heater 14. . . . . . . . . . . . . . . . . . . . . . . . . .

Connect the Hoses 15. . . . . . . . . . . . . . . . . . . . . . . . .

Prime the Hoses 15. . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjust the Heater 16. . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heated Hose 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heater 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Resistance Checks 20. . . . . . . . . . . . . . . .

Setup 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heater Sensor Probe 20. . . . . . . . . . . . . . . . . . . . .

Thermostat 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional ATC (Ambient Temperature

Compensator) 22. . . . . . . . . . . . . . . . . . . . . . . . . . .

Heater Element 22. . . . . . . . . . . . . . . . . . . . . . . . .

Hose Sensor Simulator 22. . . . . . . . . . . . . . . . . . .

Hose Control Circuit Board 23. . . . . . . . . . . . . . . .

Triac 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Triac 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hi-Limit Thermostat 26. . . . . . . . . . . . . . . . . . . . . . . .

Heater Sensor Probe 27. . . . . . . . . . . . . . . . . . . . . . .

Heater Element 28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Board 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibrating the Controls 32. . . . . . . . . . . . . . . . . . . . .

Hose Sensor Simulator, Optional ATC 34. . . . . . . .

Parts 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heater Assembly 36. . . . . . . . . . . . . . . . . . . . . . . . . .

Heated Hose Control 37. . . . . . . . . . . . . . . . . . . . . . .

Heater 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Schematics 41. . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 44. . . . . . . . . . . . . . . . . . . . .

Graco Information 44. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.