Installation

10 3A8940A

Connect Supply Wiring

Ensure the equipment is connected to a temperature

controller that limits the operating temperature to 203°F

(95°C) or less.

See Technical Specifications, page 30, for electrical

requirements.

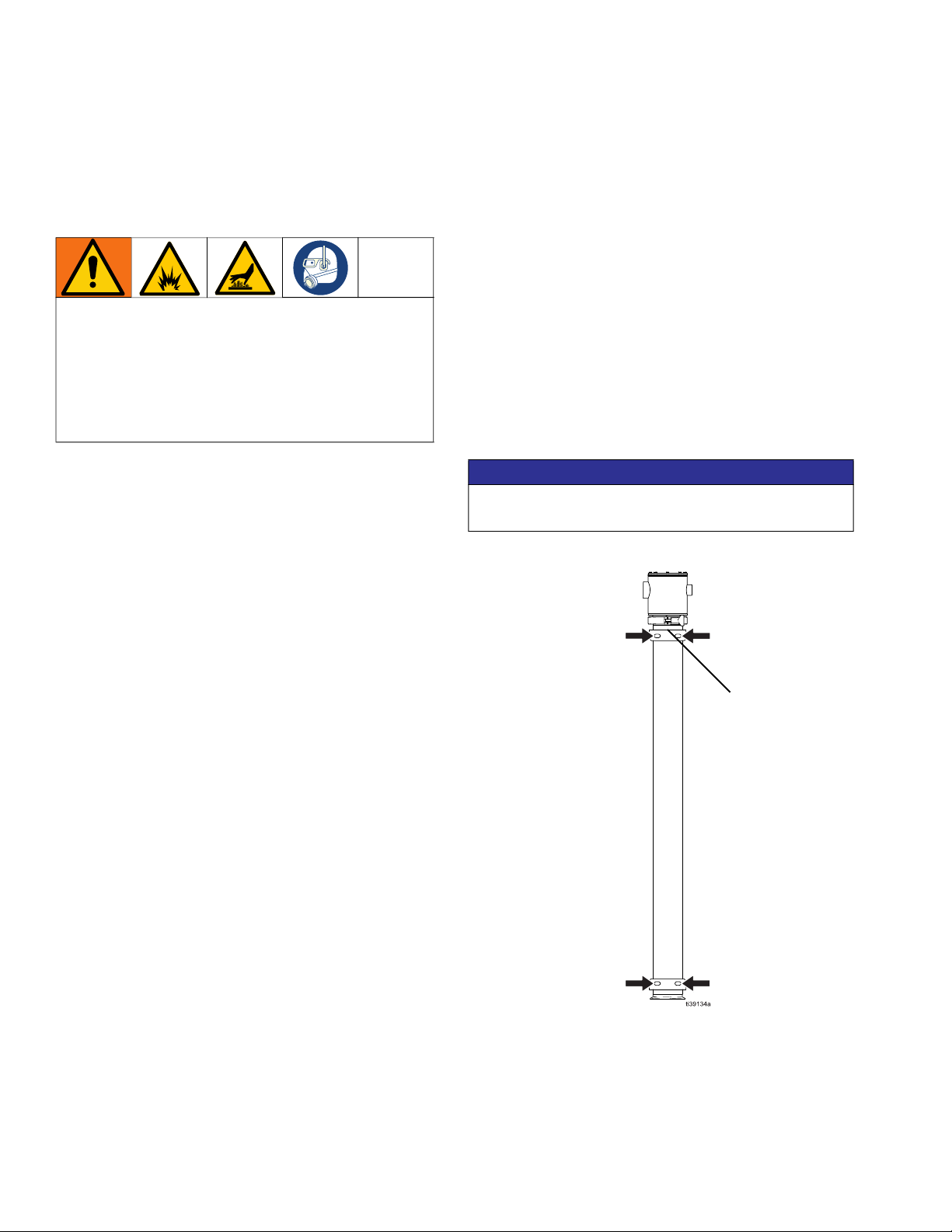

1. Ensure that the electrical disconnect (AA) to the

heater is shut off and locked.

FIG. 6: Electrical Disconnect

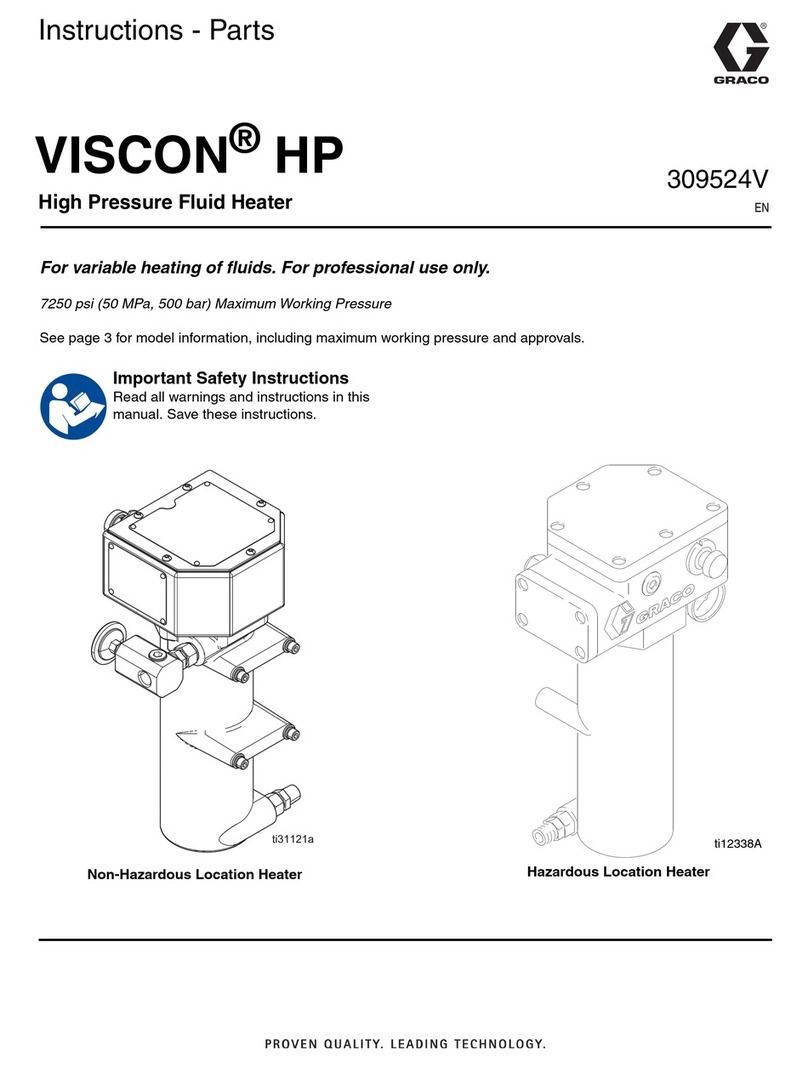

2. Remove the fasteners (9), washers (8), cap (7), and

o-ring (6) to access the electrical wiring

compartment.

3. Insert electrical wires through the electrical wiring

port (C).

4. Connect wires to terminals. See Electrical

Schematics, starting on page 23.

NOTE: Conductors and terminals used for supply

connection must be suitable for 221°F (105°C) or

greater.

NOTE: Heater terminals are 1/4-20 thread. Torque

to 75 in-lb (8.5 N•m).

5. Install the o-ring (6), cap (7), washers (8), and

fasteners (9). Torque fasteners (9) to 20in-lb

(2.2 N•m). See Torque Sequence, page 22.

FIG. 7

Connect Thermocouple

A Type J thermocouple is permanently installed in the

system. Connect the thermocouple wire (F) to your

temperature controller (required, not supplied).

Install a second temperature sensor (required, not

supplied) as close to the fluid outlet port as possible to

measure fluid outlet temperature.

Connect Over-Current Protective Devices

Prior to powering on, install external over-current

protective devices (required, not supplied) to the

equipment. See Technical Specifications, page 30, for

electrical requirements.

All electrical wiring must be done by a qualified

electrician and comply with all local codes and

regulations.

NOTICE

To prevent voltage fluctuations that may result in

equipment damage, use the proper temperature

controller, voltage, wiring, fusing, sensors, and sizing

of electrical connections for your equipment.

NOTICE

To prevent equipment damage, do not torque

terminal nuts more than 75 in-lb (8.5 N•m).

AA

NOTICE

Do not exceed the maximum operating temperature

of 203°F (95°C). Operating the equipment outside of

these conditions can result in premature heater

failure, heater short, or potentially hazardous heater

burnout.

1

Torque terminal nuts to 75 in-lb (8.5 N•m).

1

2

Torque to 20 in-lb (2.2 N•m).

C

9

8

7

6F