AHKDSERIES

ELECTRIC RESISTANCE HEAT KITS

INSTALLATION INSTRUCTIONS

I

NTRODUCTION

Product Description

The AHKD series of electric heat kits is an accessory designed for

installationwiththeDaikinDAR0904orDAR1204AirhandlerONLY.

INSTALLATIONSWITHOTHERAIRHANDLERSISNOTPERMITTED.

For installation guidelines of the DAR0904 or DAR1204, refer to

the instructions which accompany the air handler, IOD-4010 (In-

stallation & Operating Instructions).

The AHKD provides supplemental electric heat for the DAR0904/

1204. The assembly is to be installed directly to the outlet of the

DAR0904/1204 and is not to be used as an independent duct

heater.

TheAHKD20 andAHKD30 heatkits havetwo stages. A twostage

room thermostat determines the staging by room temperature.

The heat kit’s control panel is “self contained” and is equipped

with all of the safety circuit/limits required per UL1995. The heat

kit employs a terminal block for installation of the high voltage

wires used by both the heat kit and the airhandler (single point

wiring).

C

HECKING

P

RODUCT

R

ECEIVED

Upon receiving the unit, inspect it for damage from shipment.

Claims for damage, either shipping or concealed, should be filed

immediatelywiththe shipping company.Donotinstall this acces-

sory if it is determined that the integrity or safety has been com-

promised by freight damage.

Check the unit model number, specifications, and electrical char-

acteristics to determine if they are correct. In the event an incor-

rect unit is shipped, it must be returned to the supplier and must

NOTbe installed. Themanufacturer assumes noresponsibility for

installation of incorrectly shipped units.

R

EPLACEMENT

P

ARTS

ORDERING PARTS

When reporting shortages or damages, or ordering repair parts,

give the complete unit model and serial numbers as stamped on

the product.

Replacementpartsforthisproductareavailablethroughyourcon-

tractor or local distributor. For the location of your nearest dis-

tributor, consult the white business pages, the yellow page sec-

tion of the local telephone book or contact:

CONSUMER AFFAIRS

DAIKIN NORTH AMERICA LLC

7401 SECURITY WAY

HOUSTON, TEXAS 77040

855-770-5678

I

MPORTANT

S

AFETY

I

NSTRUCTIONS

RECOGNIZE SAFETY SYMBOLS, WORDS, AND LABELS

Thefollowingsymbolsandlabelsareusedthroughoutthismanual

to indicate immediate or potential hazards. It is the owner’s re-

sponsibility to read and comply with all safety information and

instructions accompanying these symbols. Failure to heed safety

information increases the risk of property damage, product dam-

age, personal injury or death.

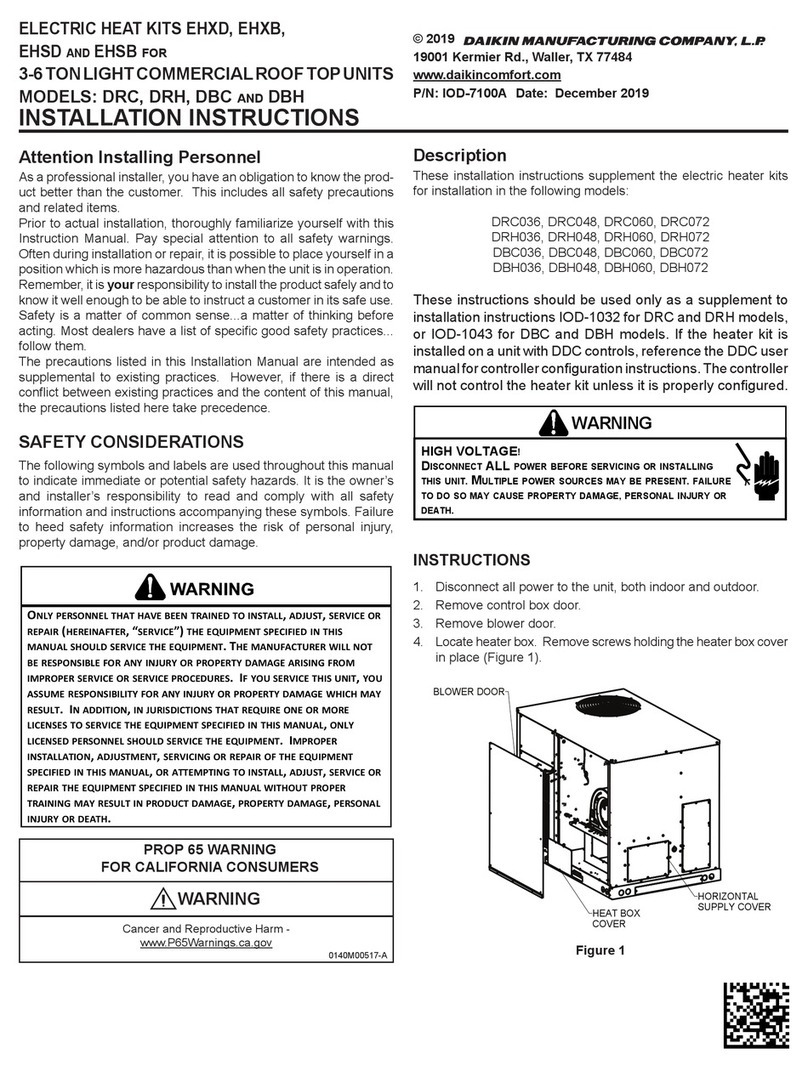

HIGH VOLTAGE!

D

ISCONNECT

ALL

POWER

BEFORE

SERVICING

.

M

ULTIPLE

POWER

SOURCES

MAY

BE

PRESENT

. F

AILURE

TO

DO

SO

MAY

CAUSE

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

.

WARNING

© 2013

5151 San Felipe, Suite 500, Houston, TX 77056

www.daikincomfort.com

P/N: IOD-7031 Date: December 2013