7

308-464

Setup

VI. Ground the system.

WARNING

To

reduce the risk of static sparking, ground the

pump and all other equipment used or located in

the spray area. Check your local electrical code for

detailed grounding instructions for your area and

type of equipment.

Ground all of this equipment.

Also read

FIRE, EXPLOSION OR ELECTROS

-

TA

TIC SHOCK HAZARD

on page 2..

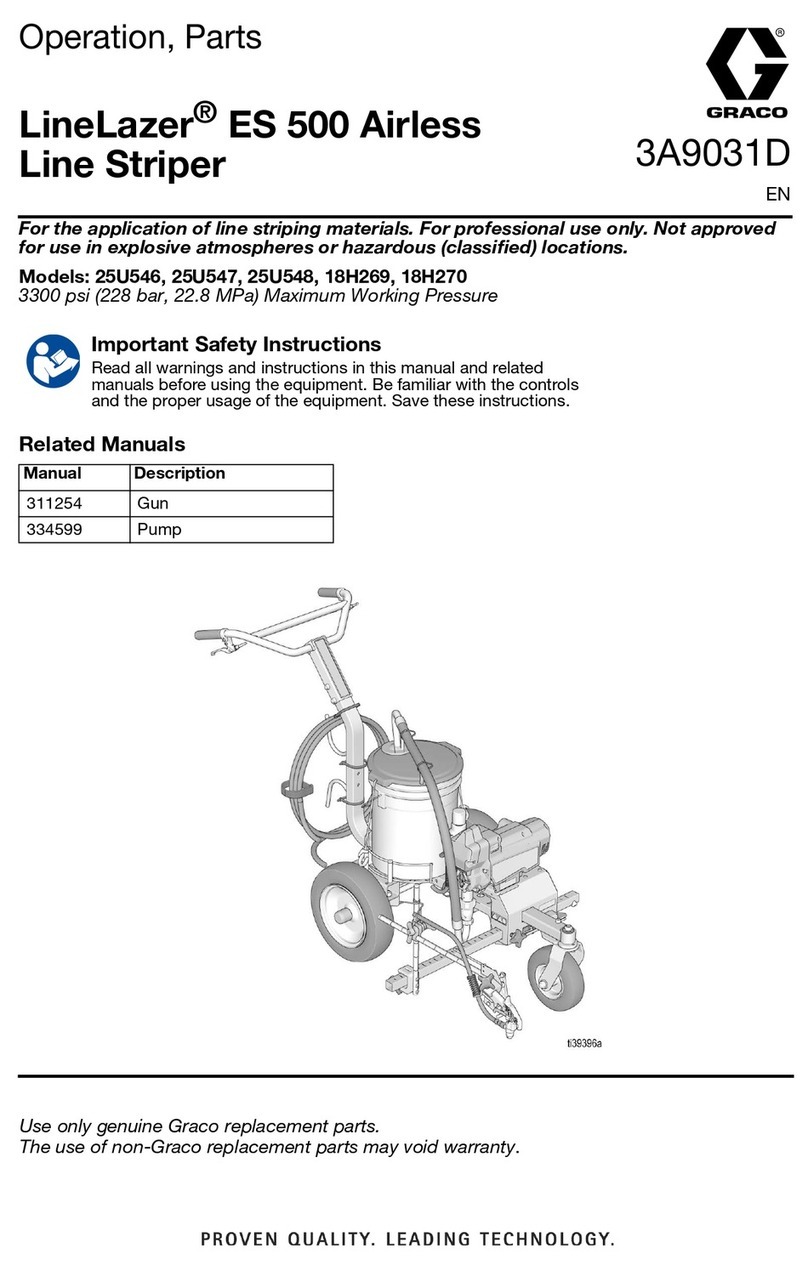

1.

Pump

: one end of the ground wire (30) is already

connected to the air motor grounding lug. Connect

the clamp end of the ground wire to a true earth

ground.

2.

Air and fluid hoses

: use only electrically conductive

hoses with a maximum of 500 feet (150 m) com

-

bined hose length to ensure grounding continuity

.

3.

Air compressor

: according to manufacturer

’

s

recommendations.

4.

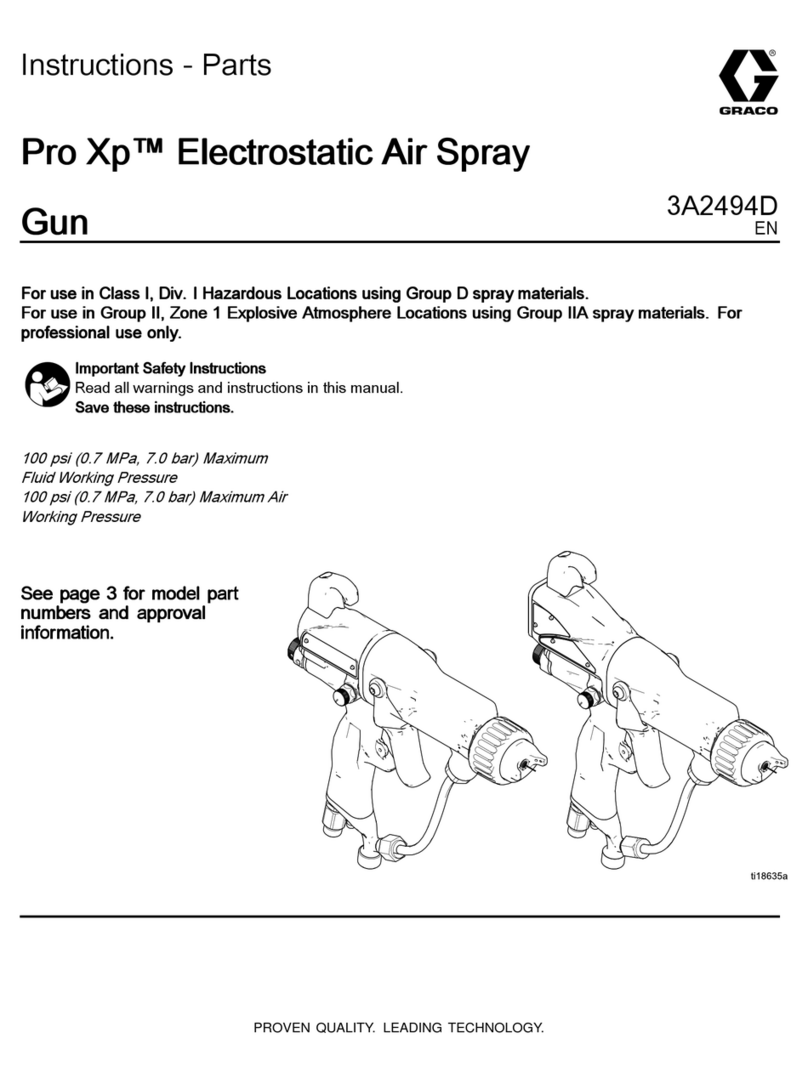

Electrostatic spray gun:

grounding is obtained

through connection to a properly grounded air

supply hose. Use only Graco electrically conduc

-

tive air supply hose (34) as supplied with this

system. Loosen the grounding lug locknut (W) and

washer (X). Insert the bare end of the air hose

ground wire into the slot in the lug and tighten the

locknut securely

. Connect the air hose ground wire

to the air motor grounding lug. See Fig. 4.

Fig. 4

2Connect

air hose ground wire to

pump grounding lug

1

W

X

30 0864

1

Pump ground wire.

Connect to a true earth ground

2

5.

Object

being sprayed:

keep the work piece

hangers clean and grounded at all times. Contact

points must be sharp points or knife edges. Use a

megohmeter or a circuit tester buzzer or light to

verify that the parts are properly grounded.

6.

All electrically conductive objects or devices in the

spray area,

including paint containers, wash cans.

7.

All persons entering the spray area:

shoes must

have conductive soles, such as leather

, or

personal grounding straps must be worn. Rubber

of plastic soles are not conductive. The operator

must not wear gloves which insulate the hand from

the spray gun. The gloves must be conductive or

modified as shown in Fig. 5. Use the gun cover

,

supplied, to help protect your hand and the gun

from overspray

.

Fig. 5

3

in. (76 mm) square

cut out and finger

of glove cut of

f

1

1

8.

The

floor of the spray area

must be electrically

conductive and grounded. Do not cover the floor

with cardboard or any non–conductive material

which would interrupt grounding continuity

.

9.

Flammable liquids

in the spray area must be kept

in approved, grounded containers. Do not store

more than the quantity needed for one shift.

10.

Fluid supply container:

according to local code.

11.

All solvent pails used when flushing

, according to

local code. Use only metal pails, which are con

-

ductive. Do not place the pail on a non-conductive

surface, such as paper or cardboard, which inter

-

rupts the grounding continuity

.