Graco RentalPro 230PC HDR User manual

Other Graco Paint Sprayer manuals

Graco

Graco RTX-650 Programming manual

Graco

Graco GM 3500 Operation manual

Graco

Graco ULTIMATE Mx 1095 A Series User manual

Graco

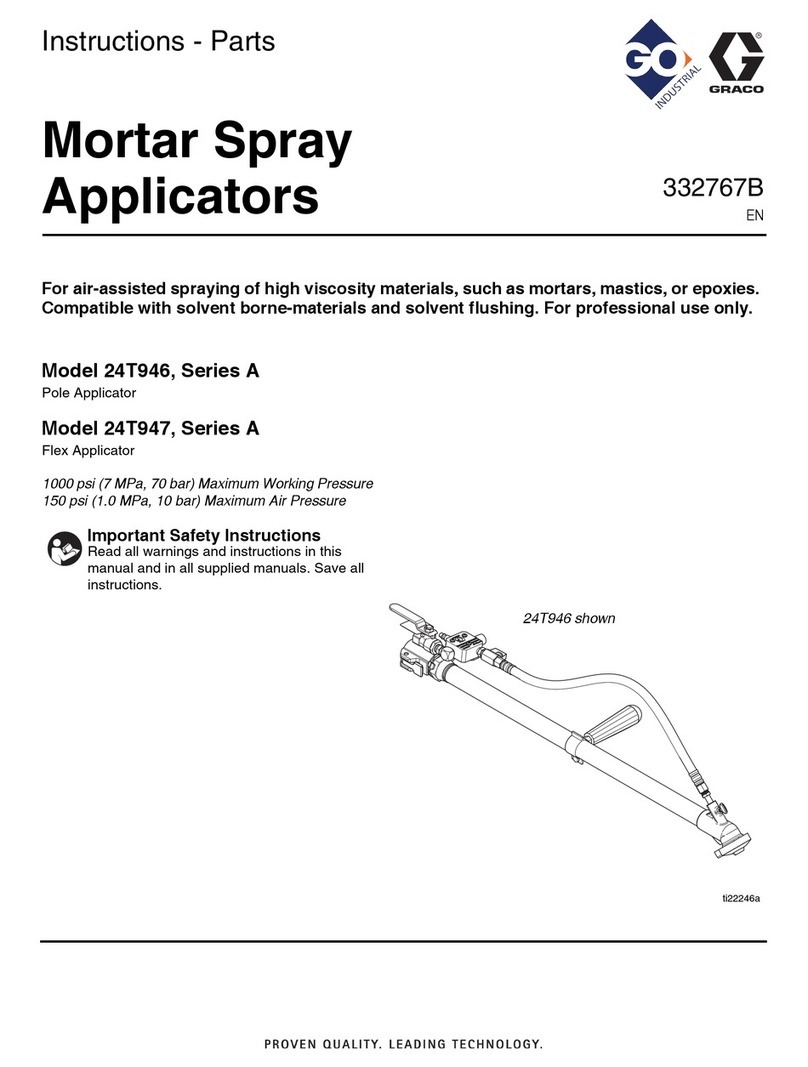

Graco 24T946 Operation manual

Graco

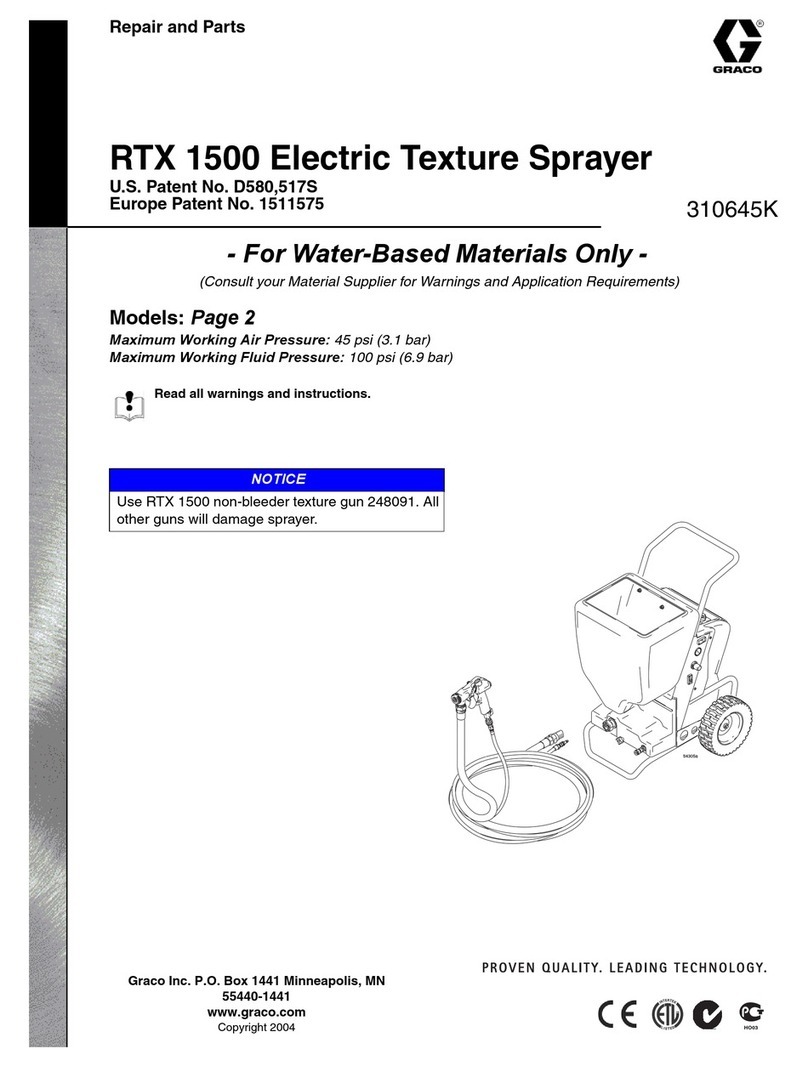

Graco 310645K Use and care manual

Graco

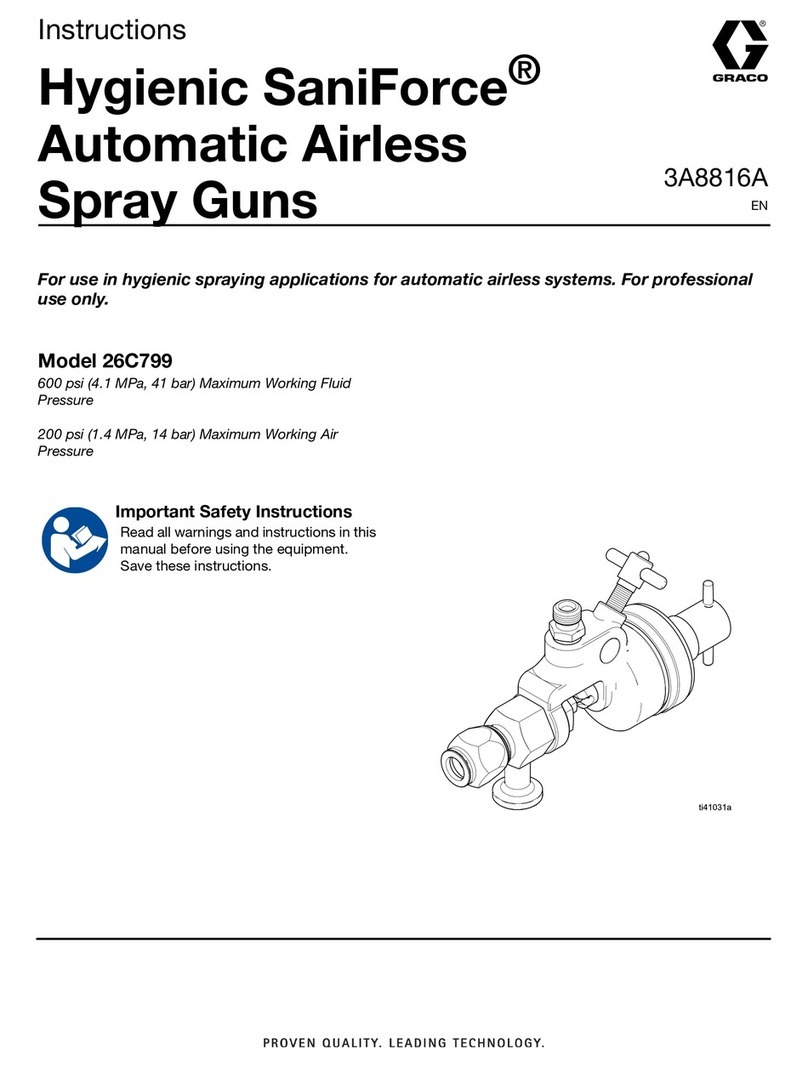

Graco SaniForce 26C799 User manual

Graco

Graco Optimiser 02017 User manual

Graco

Graco TrueCoat 360 Project Series User manual

Graco

Graco e-Xtreme Z25 Use and care manual

Graco

Graco NOVA 390 PC Guide

Graco

Graco RTX 1500 Instruction Manual

Graco

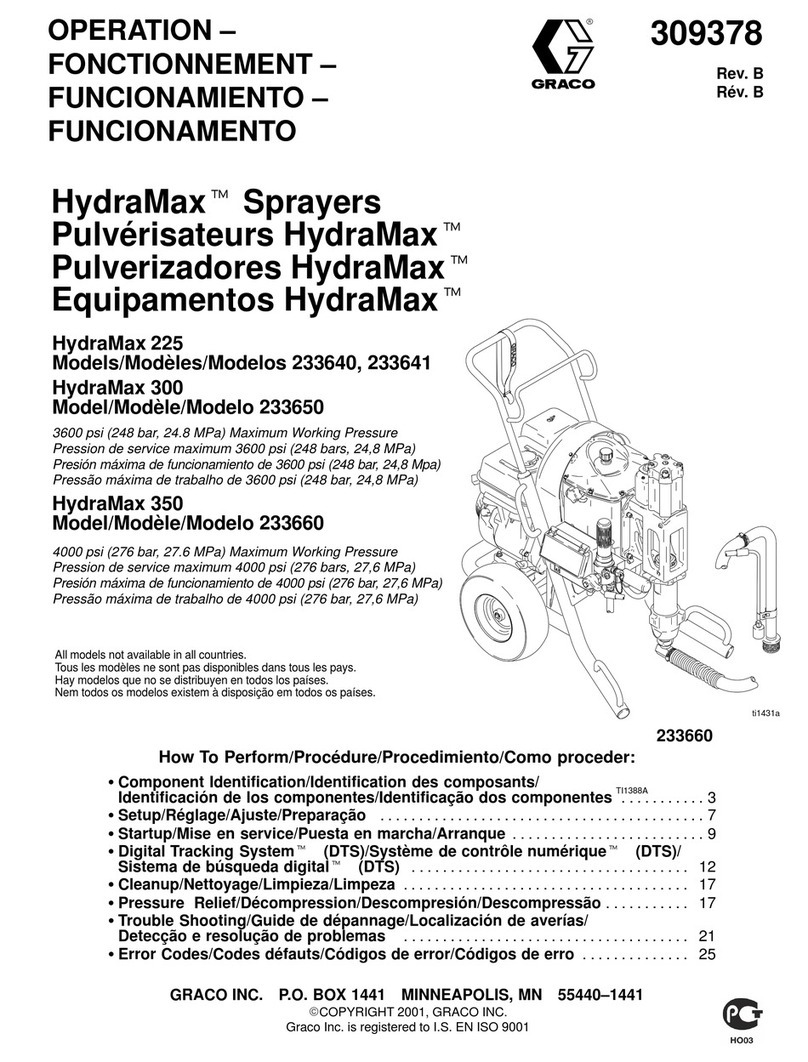

Graco HydraMax-225 233640 User manual

Graco

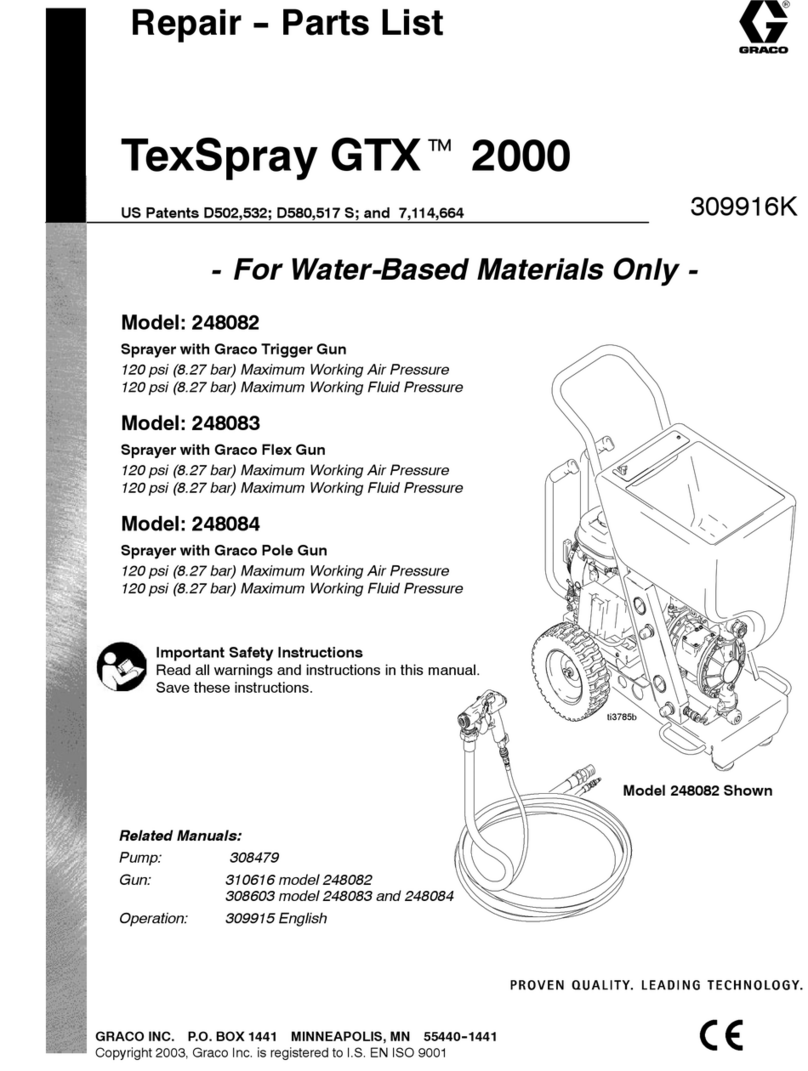

Graco TexSpray GTX Owner's manual

Graco

Graco C Series User manual

Graco

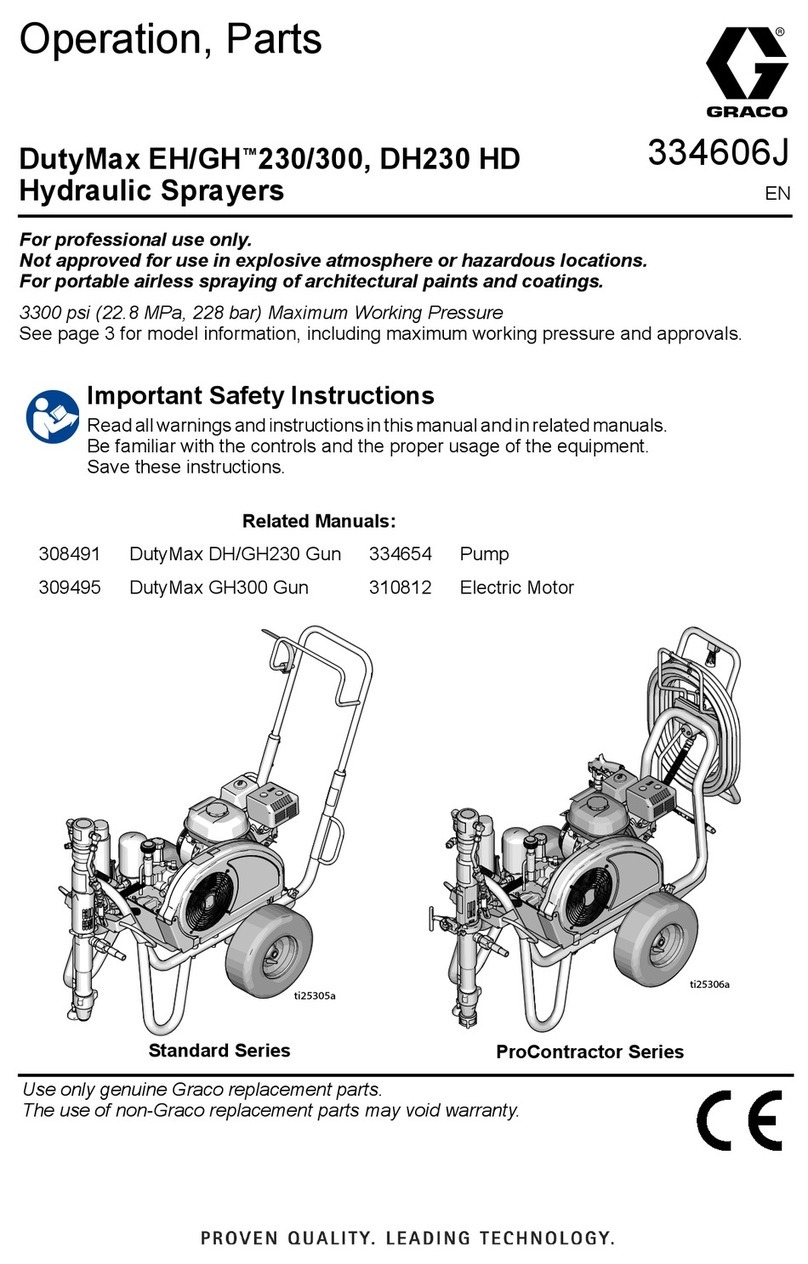

Graco DutyMax DH230 HD Guide

Graco

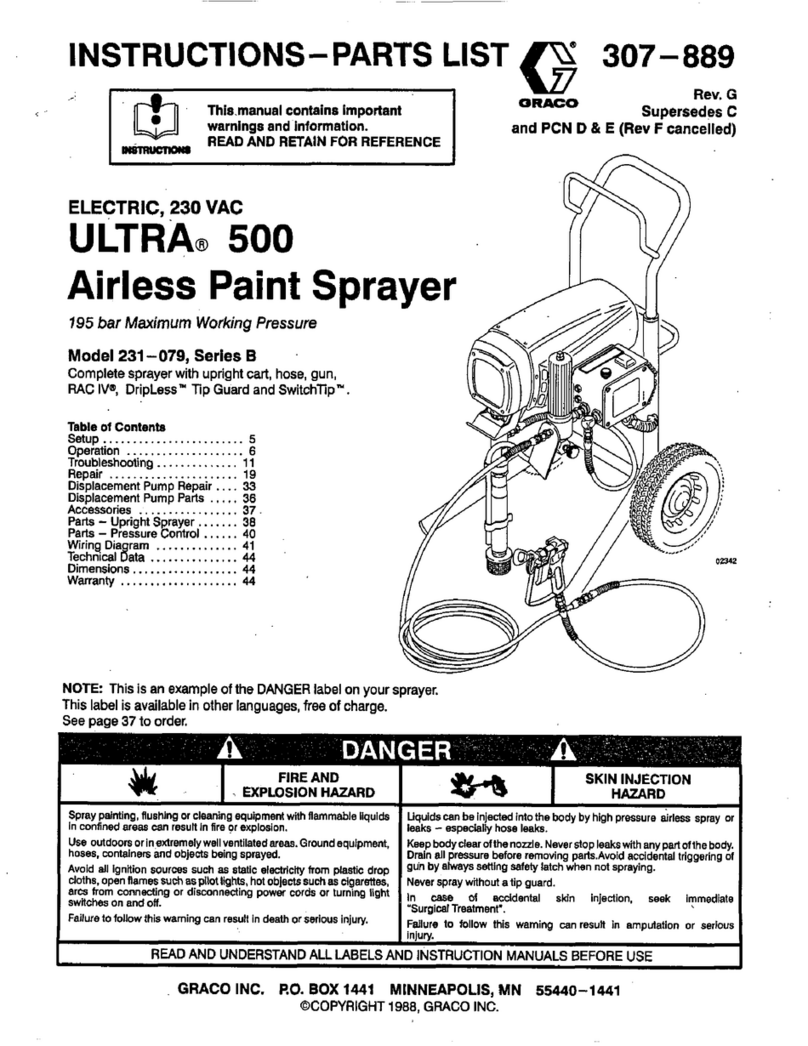

Graco Series B Operation manual

Graco

Graco GM3500 SPRAYER 231-078 Operation manual

Graco

Graco GM3000 Operation manual

Graco

Graco 24N319 Operation manual

Graco

Graco C Series Operation manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual