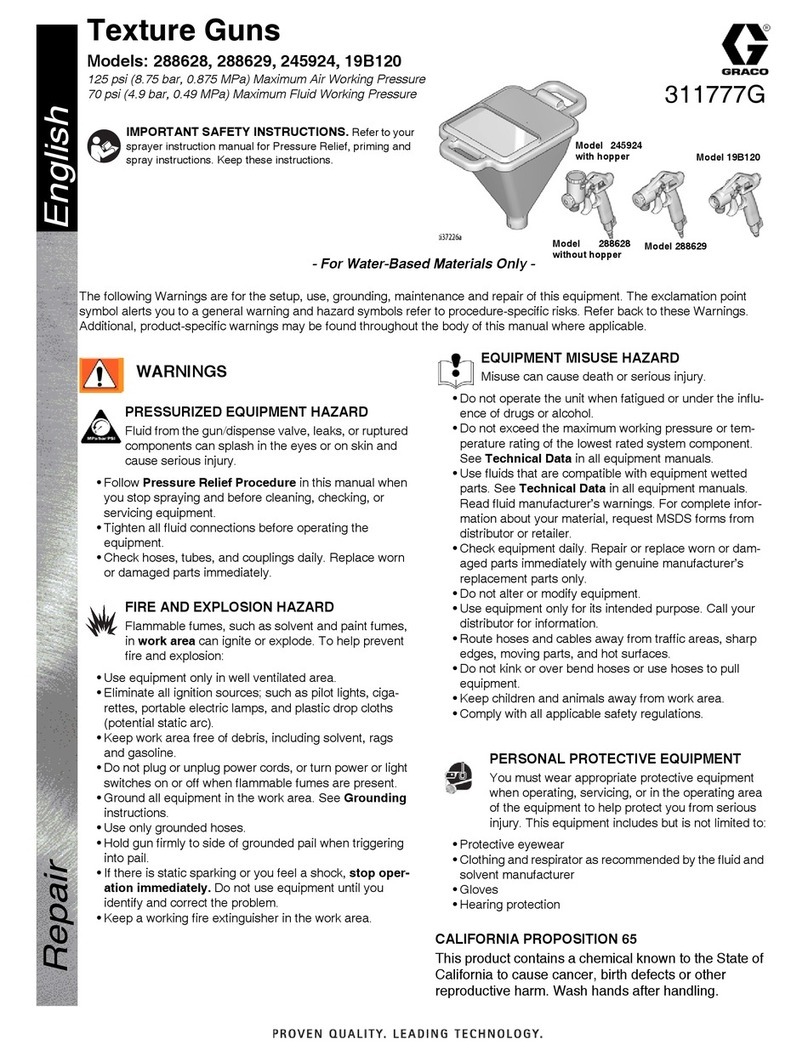

EQUIPMENT MISUSE

HAZARD

General Safe

Any misuse oft

3;

e spray equipment or accessories, such

as

Allchemicalsusedinthesprayermustbechemicallycompatible

ovemressurizina. modifvina Darts, usina incompatible chemi- with'the wetted parts given

in

the TECHNICAL DATA

on

page

Fluid

and

Solvent Compatibility

calsandfluids,o);singwornordamage~parts,cancausethem

44.

Consult your chemical supplier to ensure compatibility.

.

-.

toruPtureandresuitinfluidinjection,splashingintheeyesoron

Donotuse1,1,l~trichloroethane,methylenechloride,otherha~

the skin, or other serious bodily injury, or fire, explosion or prop-

logenated

hydrocarbon

em/ damage.

or

fluids

containing

such

vents

in

this equipment, which contains aluminum and/or zinc

oarts. Such usecould

resuitinaseriouschemicalreaction,

with

Alwayswearprotectiveeyewear,gloves,clothingandrespirator

mumworkingpressureofanycomponentoraccessoryusedin

as recommended by the fluid and solvent manufacturer. the system.

HOSE

SAFETY

High pressure fluid

in

the hoses can be very dangerous.

If

the Handle and route hoses carefully.

Do

not pull

on

hosesto move

damageormisuse,thehighpressuresprayemittedfromitcan ofthepumpandgasengine.Donotusefluidsorso1ventswhich

hose develops a leak, split or rupture due to any kind of wear, equipment. Keep hoses clear of moving parts

and

hot surfaces

cause a fluid injection injury or other serious bodily injury or

arenotcompatiblewiththeinnertubeandcoverofthehose.DO

property damage.

NOTexposeGracohosetotemperaturesabove82D

Corbelow

All

tluld

hoses

must have sprlng guards on both endsl The

-40"

spring guards help protect the hose

from

kinks or bends at

or

closet6 the coupiing which can result in hose rupture.

Hose

Grounding Continuity

all

fluid

securely

before

each

use,

High

Proper hose grounding continuity is essential to maintaining

a

groundedspraysystem.Checktheelectricalresistanceofyour

onitwhichsoecifiesthemaximumelectricalresistance.contact

pressurefluidcandislodgealoosecouplingorallowhighpres-

~uidhosesatleastonceaweek~,,your~~se~o~sn~~~a~~atag

sure spray to be emitted from the coupling.

NEVER useadamaged hose. Beforeeach use, checktheentire the hosesupplier or manufacturer for the maximum resistance

hose for cuts, leaks, abrasion, bulging cover, or damage or limits. Use a resinance meter

in

the appropriate range for your

replacethehoseimmediatelv.DONOTtrytorecouplehighDres-

ommended limits, replace

it

immediately.

An

unarounded or

.

i

movementofthehosecouplings.

lfany oftheseconditionsexist, hose to check the resistance. If

the

resistance exceeds the rec-

sure hose or mend

it

with tape or any oiher device.

A

&paired poorly grounded hose can make your system hazardous.

Also

hose cannot contain the high pressure fluid. read

FIRE

OR

EXPLOSION HAZARD.

FIRE

OR

EXPLOSION

HAZARD

and hose. If every part of the spray equipment is not properly

Staticelectricityiscreatedbytheflowoffluidthroughthepump

grounded, sparking may occur, and the system may become

hazardous. Sparking may also occur when plugging in or un-

plugging a power supply cord or using a gasoline engine.

Sparks can ignite fumes from solvents and the fluid being

sprayed, dust particles and other flammable substances,

whether you are spraying indoors or outdoors, and can cause

a fire or explosion and serious bodily injury and property dam-

age.

Ifyouexperienceanystaticsparkingorevenaslightshockwhile

the entire system for proper grounding.

Do

not use the system

usingthisequipment,STOPSPFlAYlNGIMMEDIATELY.Check

again until the problem has been identified and corrected.

To reduce the risk of static soarkina. around the soraver and all

Grounding

other spray equipment used or-located in the sljray area.

tions for your area and type

of

equipment. BE SURE

to

ground

CHECKyourlocalelectricalcodefordetailedgroundinginstruc-

all of this spray equipment:

1.

Sprayer: connect a ground wire and clamp (supplied) to a

true earth ground.

2.

Fluidhosest use only grounded hoses with a maximum of

150mcombinedhoselengthtoensuregroundingcontinu-

ity. See Hose Groundlng Contlnulty.

3.

Spraygun:obtaingroundingthroughconnectiontoaprop-

erly grounded fluid hose and sprayer.

4.

Object being sprayed: according to local code.

5.

Fluid

suppby

container: according to local code.

6.

All

solvent pails used when flushing, according to local

code.

Use

only metal pails, which areconductwe.

Do

not

placethepailonanon-conductivesurface,suchaspaper

or cardboard, which interrupts the grounding continuity.

7.

To

maintain

grounding

continuify when flushing

or

relieving

prsssure, always hold a metal pati of the gun firmly to the

side of a grounded metal pail, then trigger the gun.

Flushing

Safety

AeducetheriskofRuidiniectioniniurv,staticsparkina,orsplash-

ing byfollowing

theflushhgprocediregivenonpa~e

11 iind 12

ofthis manual. FollowthePressure

Rsllef

Procedureon page

the gun firmly to the side of a grounded metal pail and use the

4,

and remove thespray tip beforeflushing. Holdametal partof

lowest possible fluid pressure during flushing.

-

MOVING PARTS

HAZARD

-

Moving parts

can

pinch or amputate your fingers or other body

parts. KEEP CLEM of moving parts when starting or operating

the sprayer. Follow the Pressure

Rsllef

Procedure

on

page

4

before checking or servicing any part ofthe sprayer, to prevent

it

from starting accidentally.

-

IMPORTANT

-

UnitedStatesGovernmentsafetystandardshavebeenadopted

undertheOccupati0nalSafetyandHealthAct.Thesestandards

struction Standards, Part 1926

-

should be consulted.

-

particularly the General Standards, Part 1910,

and

the Con-

.."

"*

c