2334194A

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

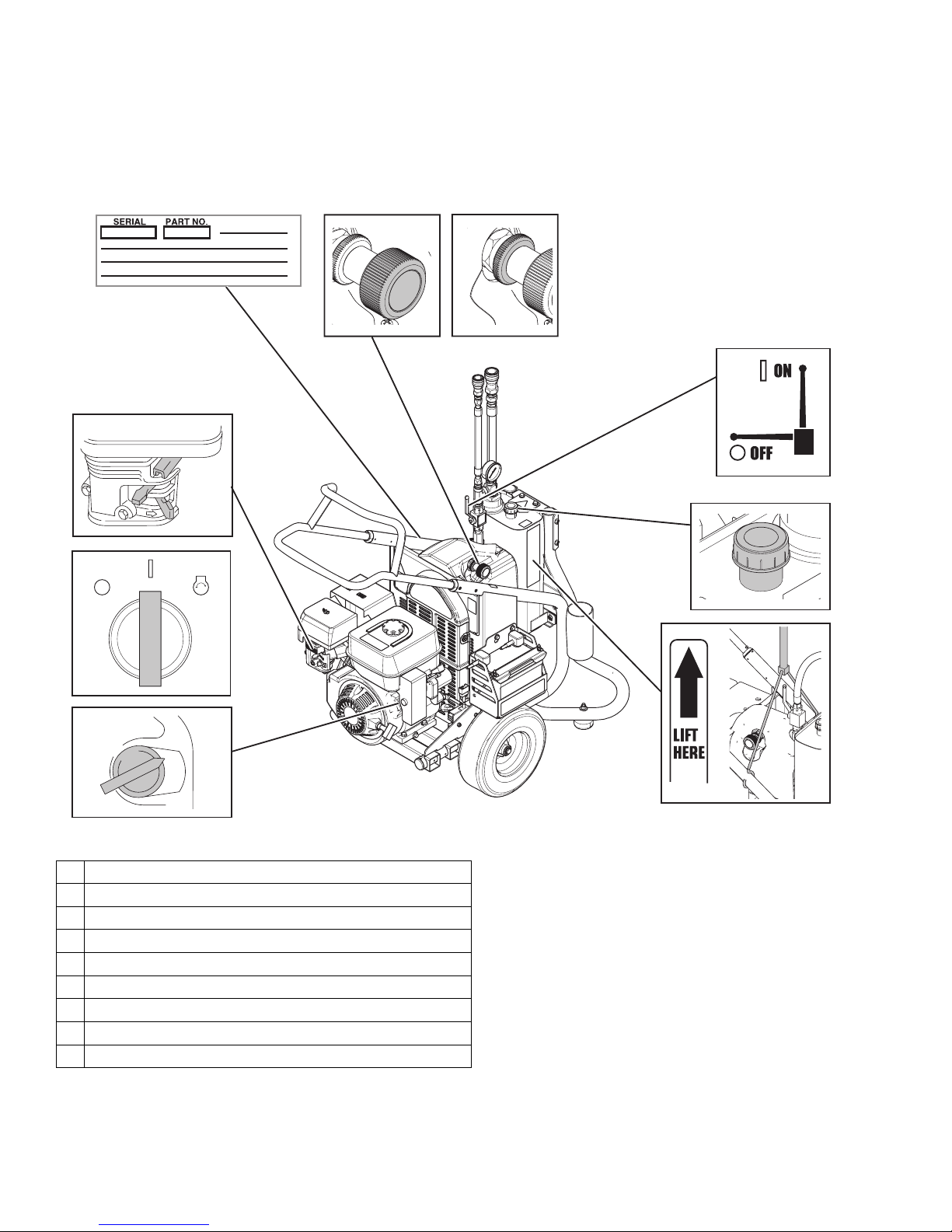

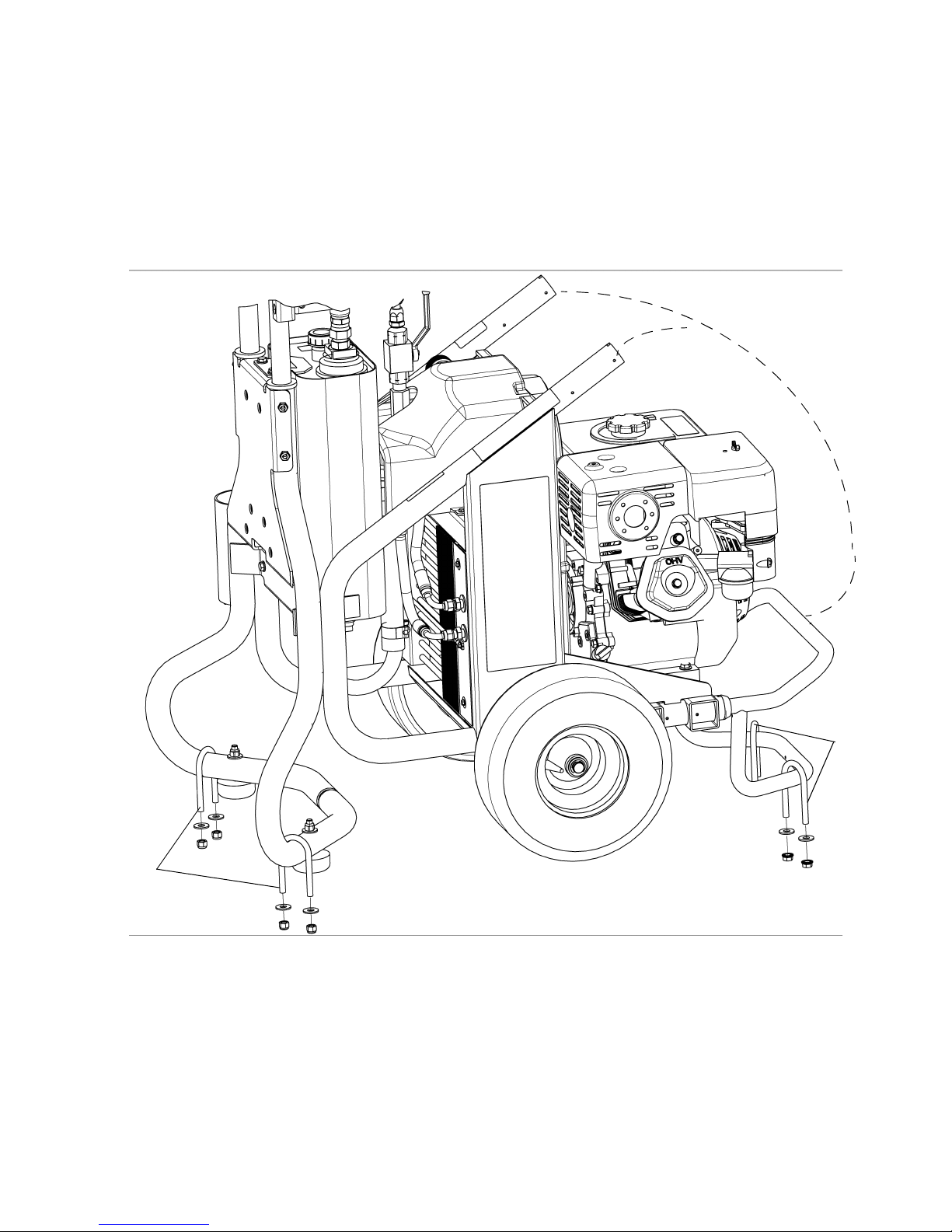

Component Identification . . . . . . . . . . . . . . . . . . . . 6

Lift Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Removing Handle . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fixed Mounting (optional) . . . . . . . . . . . . . . . . . . 8

Repositioning Handle . . . . . . . . . . . . . . . . . . . . . 8

Securing Unit to Vehicle Bed . . . . . . . . . . . . . . . . . 9

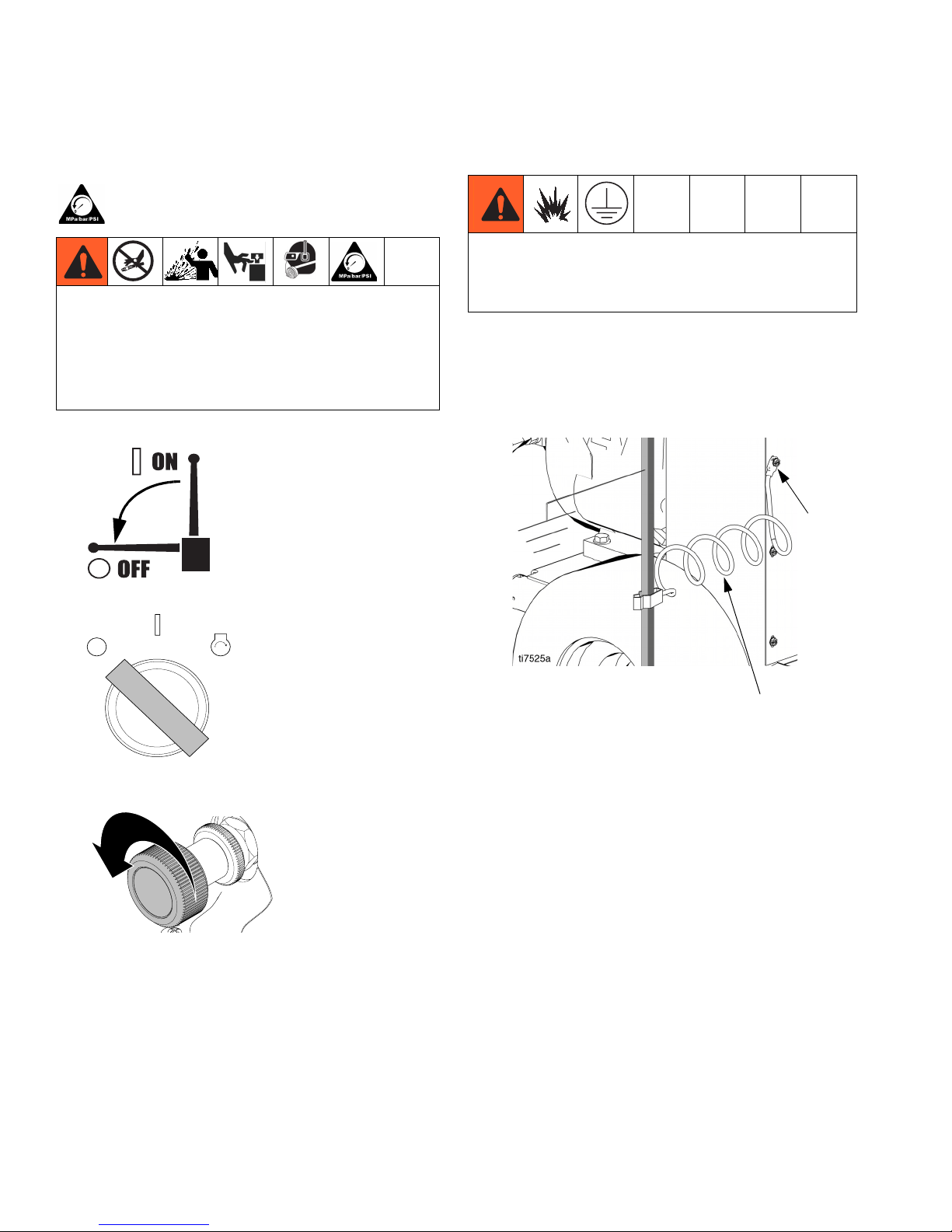

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 10

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Spraying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Compensator Seal Replacement . . . . . . . . . . . . . 16

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

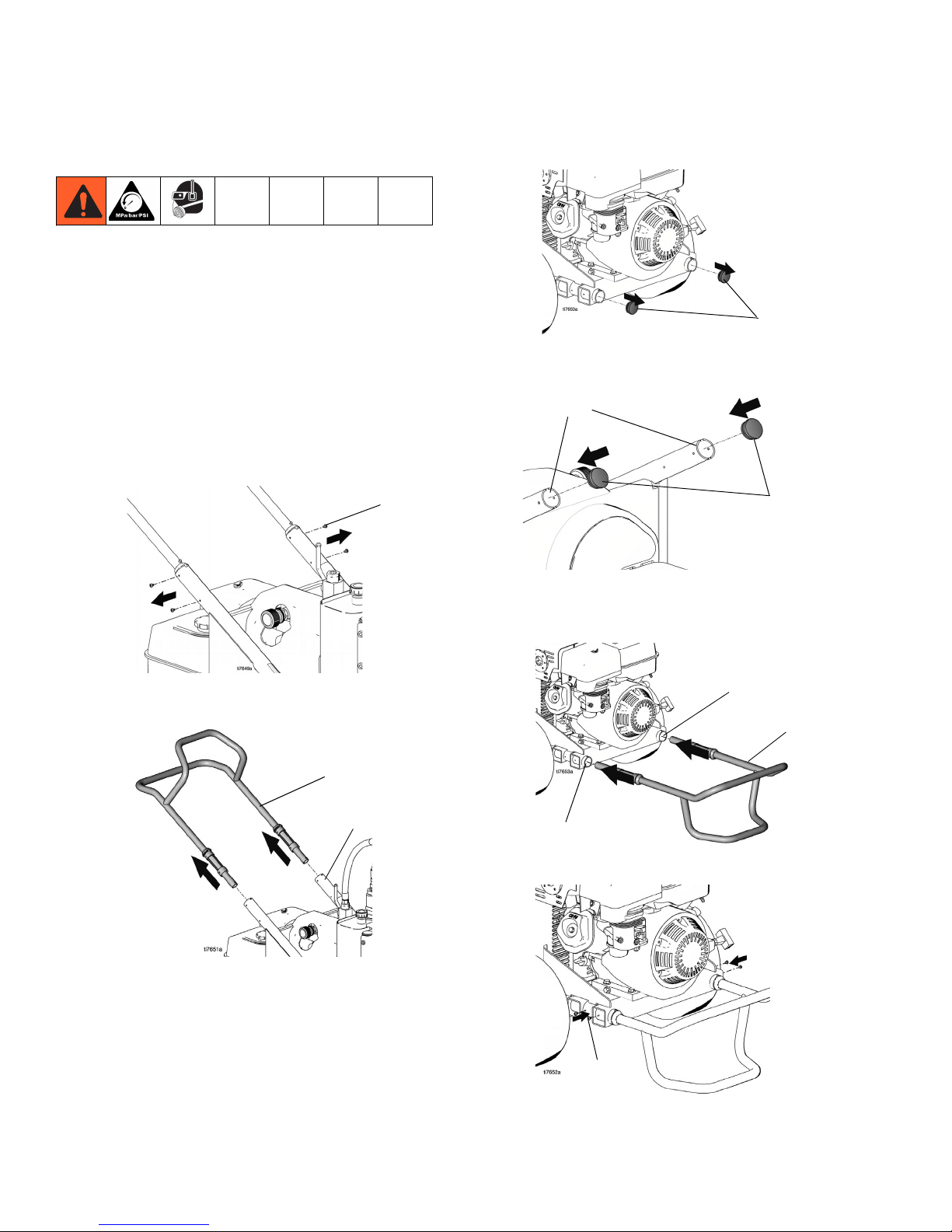

Hydraulic Pump Replacement . . . . . . . . . . . . . . . 17

Changing Hydraulic Oil . . . . . . . . . . . . . . . . . . . 17

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Belt Removal and Installation . . . . . . . . . . . . . . . 21

Replacing Oil Reservoir . . . . . . . . . . . . . . . . . . . . 22

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Changing Hydraulic Oil Filter . . . . . . . . . . . . . . . . 25

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

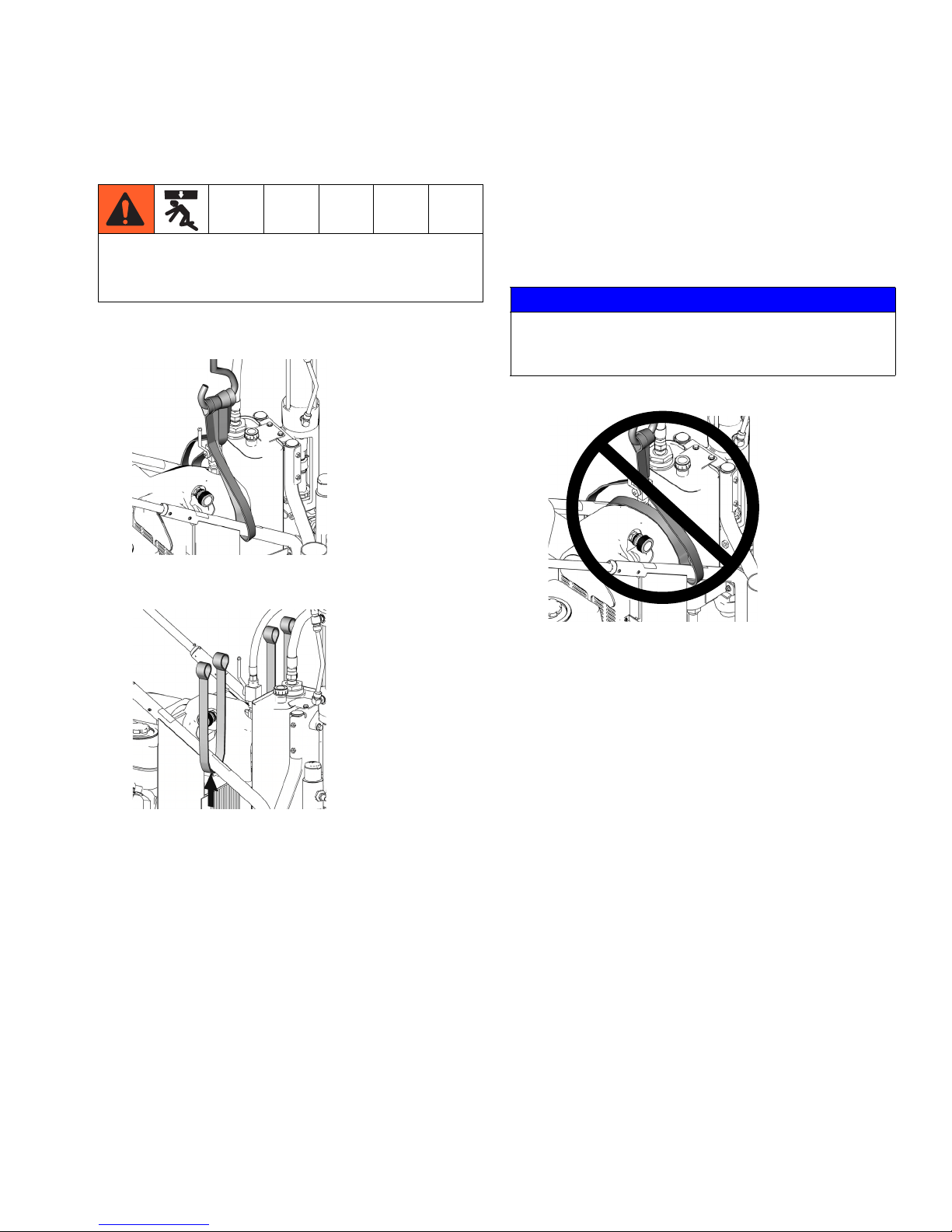

Cooler Replacement . . . . . . . . . . . . . . . . . . . . . . . 26

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Engine Replacement . . . . . . . . . . . . . . . . . . . . . . . 28

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Engine Replacement . . . . . . . . . . . . . . . . . . . . . 29

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . 30

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Frame Parts List . . . . . . . . . . . . . . . . . . . . . . . . 33

Frame (continued) . . . . . . . . . . . . . . . . . . . . . . . . . 34

Frame (Continued) Parts List . . . . . . . . . . . . . . 35

Hydraulic Pump and Reservoir . . . . . . . . . . . . . . . 36

Hydraulic Pump and Reservoir Parts List . . . . . 37

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 40