I

hose develops a leak, spilt or rupture due to any kind of wear,

High pressure fluld

In

the hoses can be very dangerous. If the

)

cause

a

fluld Injection injury or other serious bodily Injury or prcp-

damage or misuse, the hlgh pressure spray emltted from

It

can

erty damage.

ALL FLUID

HOSES

MUST HAVE SPRING GUARDS ON

BOTH ENDS! The spring guards help protect the hose from

kinks or bends at or close tc the coupling which can result In hose

rupture.

TIGHTEN all fluid connections securely before each use. High

pressure fluid can dislodge a loose coupling or allow hlgh pres-

sure spray to be emltted from the coupling.

NEVER

use a damaged hose. Before each use. checkthe entire

hose for cuts, leaks. abraslon, bulging cover. or damage or

movement of the hose coupllngs. If any of these conditions ex-

pressure hose or mend

It

with tape or any other devlce.

A

re-

1st. replace the hose immediately.

DO

NOT

try

to recouple high

palred hose cannot safely contaln the hlgh pressure fluid.

hoses to move equipment.

Do

not use fluids which are not com-

HANDLE AND

ROUTE

HOSES CAREFULLY.

Do

not pull on

patible with the inner tube and cover of the hose.

DO

NOT ex-

pose Graco hoses to temperatures above

1800

F

(820

C)

or

be-

low

-4OO

F

(-400

C).

Hose

Grounding Continuity

Proper hose grounding continuity

IS

essential to malntainlng a

grounded spray system. Check the electrical resistance of your

have a tag on

It

which specifies the maxlmum electrical resls-

air and fluid hoses at least once a week. If your hose does not

tance. contact the hose supplier or manufacturer for the maxl-

mum resistance limits. Use a resistance meter In the approprl-

tance exceeds therecommended

IlmltS.

replaceltlmmedlately.

ate range for your hose to check the reslstance. If the resls-

hazardous. Also. read-FIRE

OR

EXPLOSION HAZARD. be-

An ungrounded or poorly grounded hose can make your system

low.

parts. KEEP CLEAR of moving parts when starting or operating

Moving parts can pinch or amputate Your flngers or other body

the pump. Before checklng or servlclng the pump or any system

component, follow

the

Pressure Rellef Procedure on page

2.

to prevent the pump from starting accidentally.

Static electricity Is created by the flow of fluld through the pump

and hose. If every part of the spray equipment

1s

not properly

grounded, sparking may occur, and the system may become

hazardous. Sparklng may also occur when plugging In or unplug-

ging a power supply cord. Sparks can Ignite fumes from solvents

and the fluid being sprayed, dust partlcles and other flammable

substances. whether

you

are spraylng indoors or outdoors, and

can cause a fire or exploslon and serious bodily Injury and prcp-

erty damage.

Do

not plug In or unplug any power supply cords In

the spray area when there Is any chance

of

Igniting fumes still In

)

the air.

uslng thls equipment. STOP SPRAYING IMMEDIATELY.

If

you experlence any static sparking or even a slight shock while

Check the entire system for proper grounding.

Do

not use the

system again until the problem has been Identifled and ccr-

rected.

"""""FI

To reduce the rlsk of Static sparking. ground the pump, object

being sprayed. and all other spray equipment used or located

in

the snrav area. CHECK vour local electrlcal code far detailed

I

~~~ ~

grounding Instructionsfor your area and type of equlpment. BE

SURE to ground all

of

this spray equlpment:

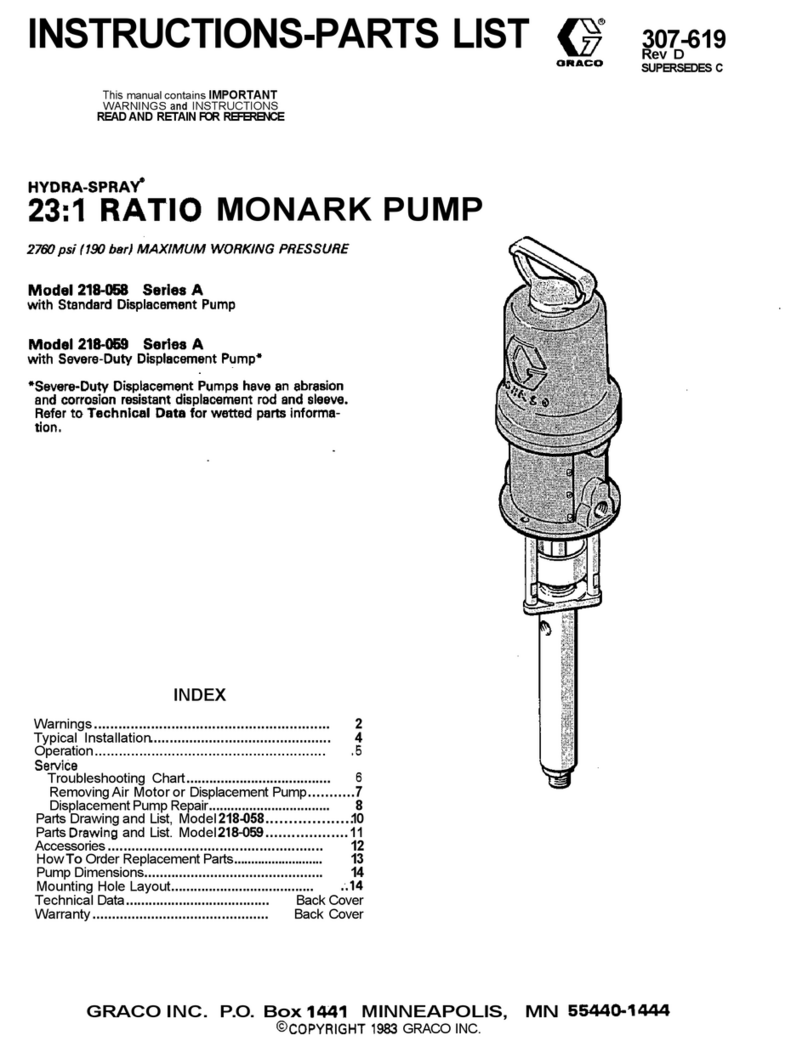

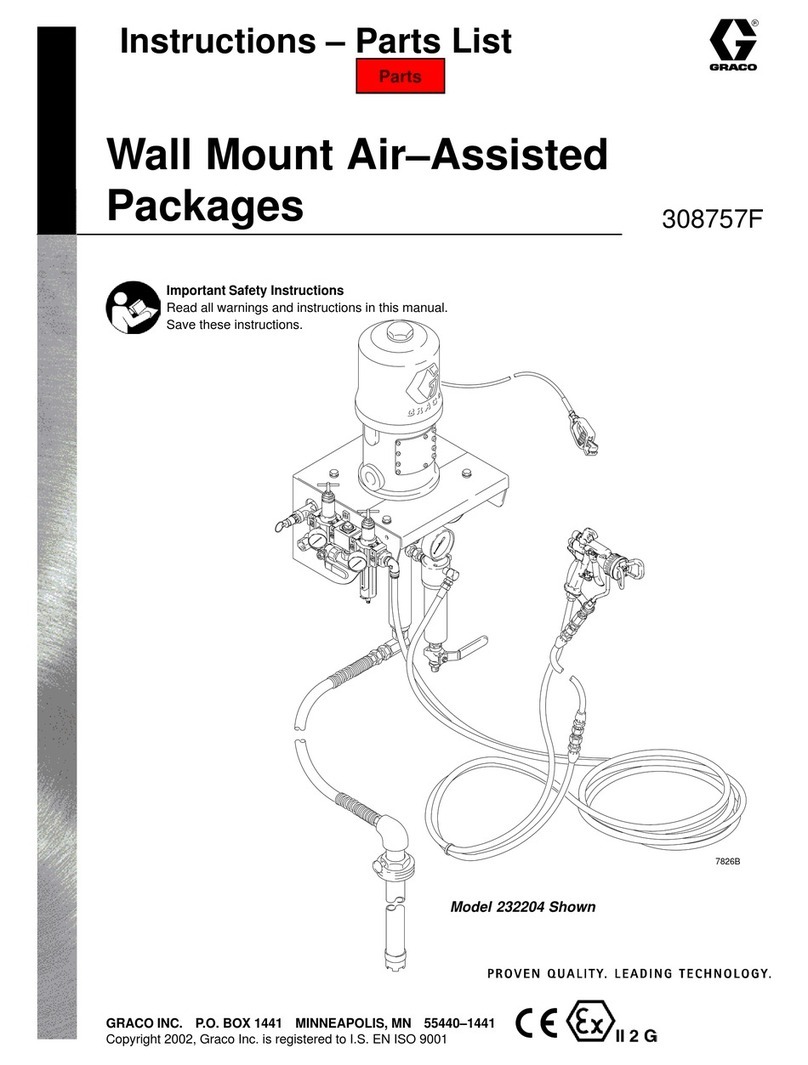

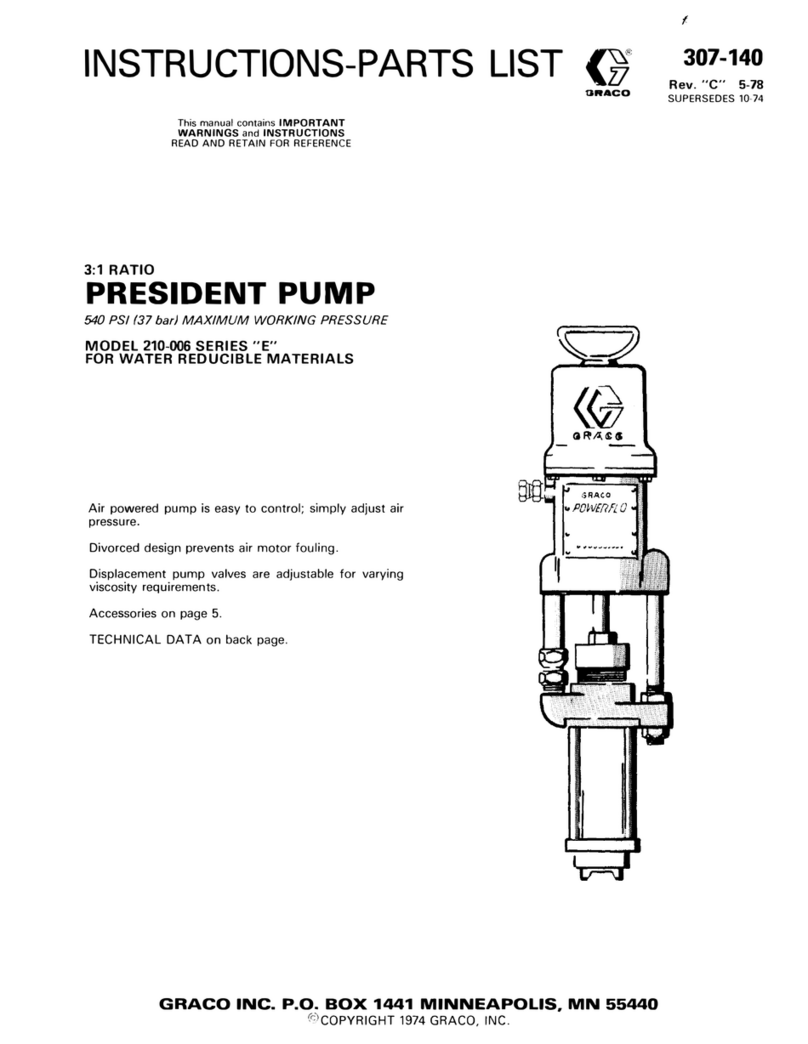

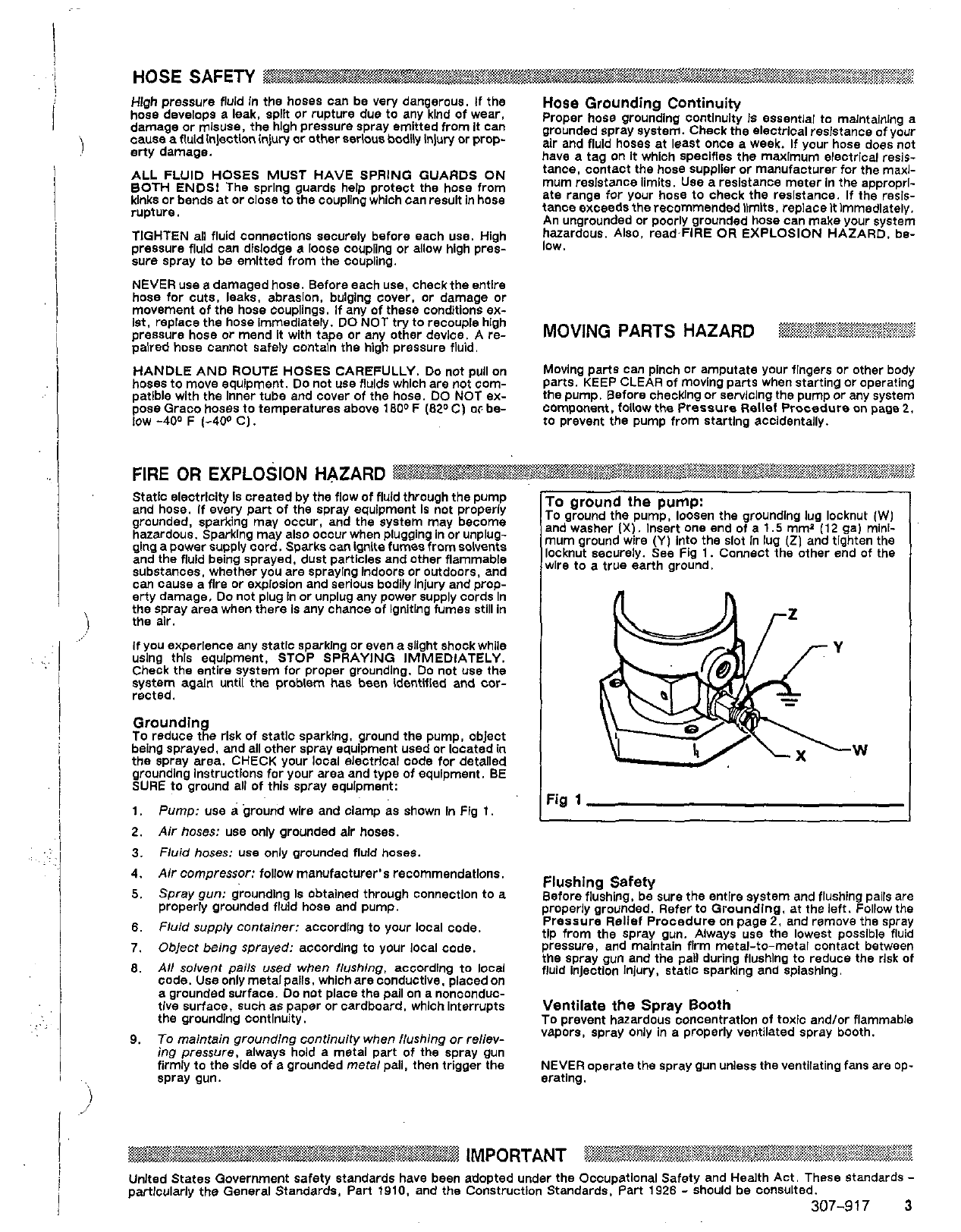

1,

Pump: use

a

ground wlre and clamp as shown

in

Fig

1,

2.

Air

hoses: use only grounded

alr

hoses.

3.

Fluid

hoses: use Only grounded fluld hoses.

4.

Air

compressor: follow manufacturer's recommendations.

5.

Spray gun: grounding

Is

obtained through connection to a

6.

Fluid

supply coniainer: accordlng to your local code.

7.

Obleci being sprayed: according to your local code.

,~~~~

~~~ ~ ~~

properly grounded fluid hose and pump.

8.

All

soiveni pails used when flushing. accordlng to local

code. Use only metal pails. which are conductive, placed on

a grounded surface.

Do

not place the pall on a nonconduc-

tlve surface. such as paper or cardboard, which Interrupts

the groundlng contlnuity.

8.

All

soiveni pails used when flushing. accordlng to local

code. Use only metal pails. which are conductive, placed on

a grounded surface.

Do

not place the pall on a nonconduc-

tlve surface. such

as

naoer or cardboard. which lnterructs

9.

To

mainiain groundlng coniinuity when flushing or reliev-

ing

pressure, always hold a metal part of the spray gun

firmly to the side of a grounded meial pall, then trigger the

spray gun.

;I

'0

ground the pump:

'0

ground the pump, loosen the groundlng lug locknut

(W)

md washer

(X).

Insert one end of a

1.5

mmz

(12

gal mini-

ium ground wire

(Y)

Into the slot In lug

(21

and tighten the

lcknut securely. See Fig

1.

Connect the other end of the

/Ire to a true earth ground.

W

'ig

1

Before flushing, be sure the entlre system and flushing pails are

Flushing Safety

properly grounded. Refer to Groundlng, at the left. Follow the

Pressure Rellef Procedure on page

2,

and remove the spray

tip from the Spray gun. Always use the lowest possible fluid

pressure. and malntaln flrm metal-to-metal contact between

the spray gun and the pall during flushlng to reduce the rlsk of

fluid Injection Injury, statlc sparking and splashing.

Ventilate the Spray Booth

TO prevent hazardous concentratlon of toxic andlor flammable

vapors, spray Only

In

a properly ventilated spray booth.

NEVER

operate the spray gun unless the ventilating fans are op-

erating.