7

306–694

Installation

NOTE: Reference numbers and letters in parentheses

in

the text refer to the callouts in the figures and

the

parts drawing.

If

you supply your own accessories, be sure they

are adequately sized and pressure–rated to

meet

the system’

s requirements.

The Typical Installation drawing on page 6 shows the

pump

being used for continuous duty over

extra long cir

-

culating lines with multiple spray outlets. This drawing is

only a guide for selecting and installing system compo-

nents and accessories. Contact your Graco distributor

for help in designing a system to suit your particular

needs.

SYSTEM

ACCESSORIES

Refer to the T

ypical Installation drawing on page 6.

WARNING

T

wo accessories are required in your system: a

bleed-type master air valve (C) and a fluid drain

valve (G). These accessories help reduce the risk

of serious injury including fluid injection, splashing

in the eyes or on the skin, and injury from moving

parts if you are adjusting or repairing the pump.

The

bleed-type master air valve

relieves air trapped

between this valve and the pump after the air is

shut of

f. T

rapped air can cause the pump to cycle

unexpectedly

. Locate the valve close to the pump.

The

fluid drain valve

assists in relieving fluid pres

-

sure in the displacement pump, hose, and gun.

T

riggering the gun to relieve pressure may not be

sufficient.

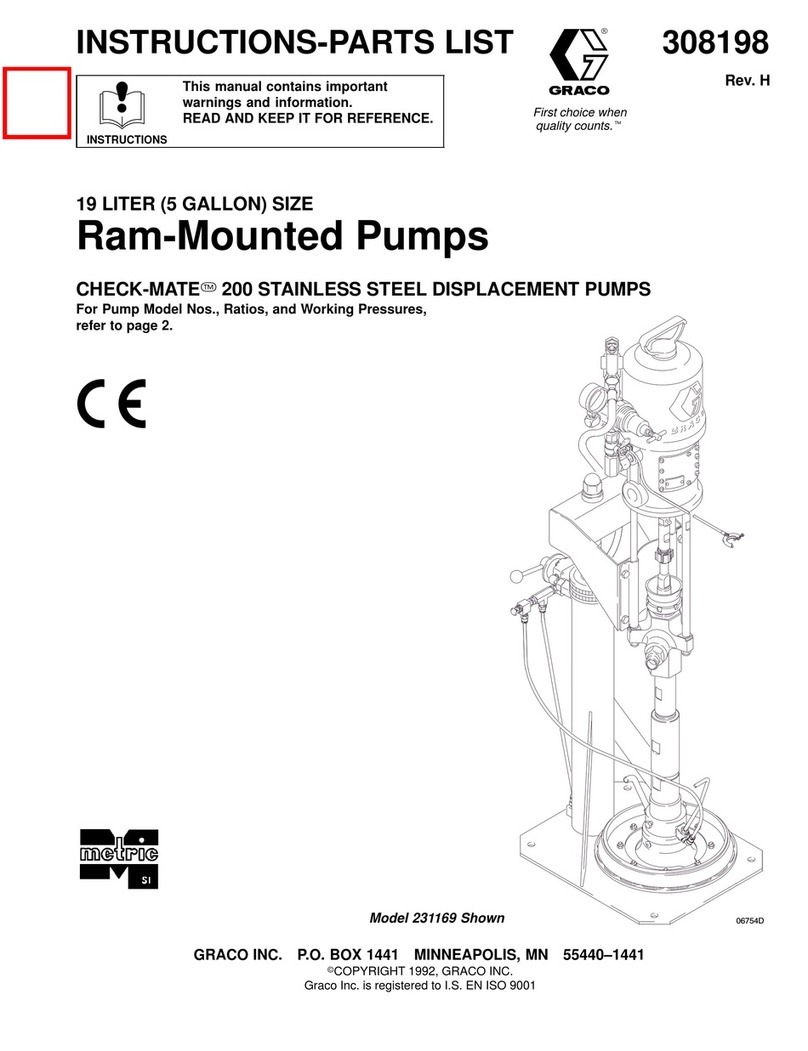

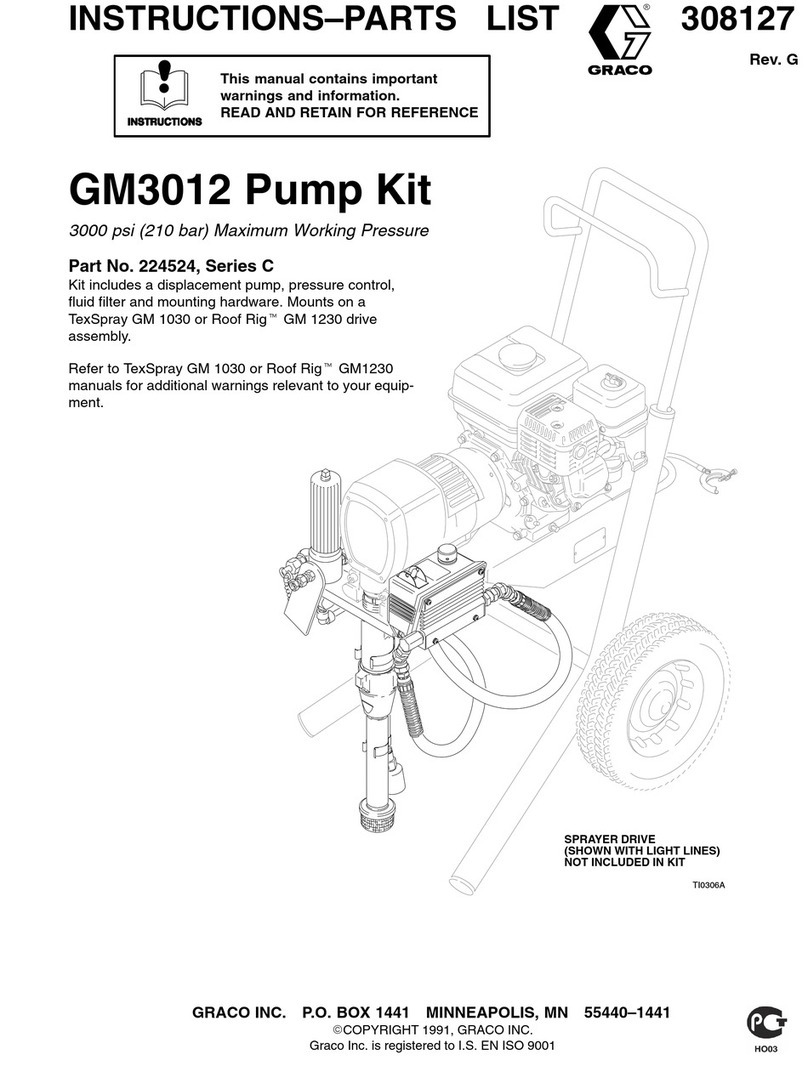

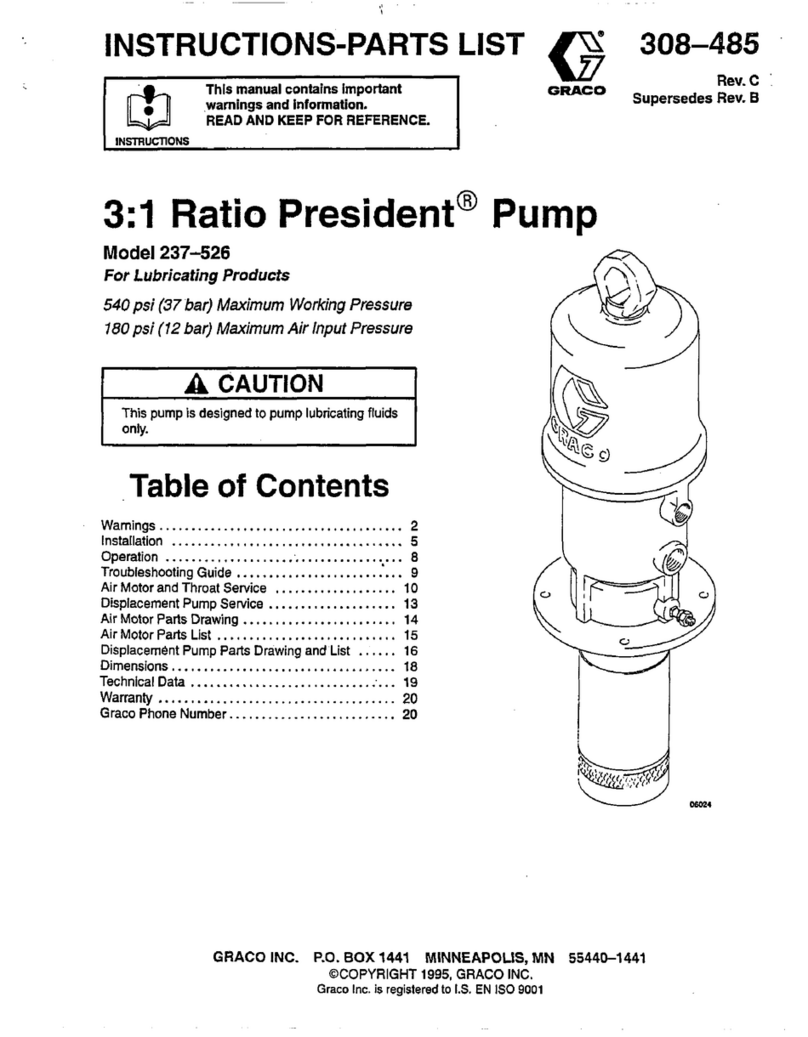

Mounting the Pump

Refer to the Dimensions on page 18, and mount the

pump

to suit the type of installation planned. If

you are us

-

ing a wall bracket, be sure the wall is strong enough to

support the weight of the pump, bracket, accessories,

and

operating stress.

Air Line Accessories

Install

the following

accessories in the order shown in the

Typical

Installation, using adapters as necessary:

A

pump runaway valve

(A

) senses when the pump

is

running too fast and automatically shuts of

f the air to

the

motor

. A pump which runs too fast can be serious

-

ly

damaged. Install closest to the pump air inlet.

An

air line lubricator (B)

provides automatic air mo

-

tor

lubrication.

A

bleed–type master air valve (C)

is required in your

system to relieve air trapped between it and the air

motor

when the valve is closed (see

the

WARNING

at

left).

Be sure the bleed valve is

easily accessible from

the pump, and is located downstream from the air

regulator.

An

air

regulator (D)

controls pump speed and outlet

pressure by adjusting the air pressure to the pump.

Locate

the regulator close

to the pump, but

upstream

from

the bleed–type master air valve.

An air line filter (E) removes harmful dirt and mois-

ture

from the compressed air supply

.

A second bleed–type air valve (C) isolates the air

line

accessories

for servicing. Locate upstream from

all other air line accessories.

When

dropping the air line down from the main air supply

,

always

install plumbing in a vertical loop as shown in the

Typical

Installation.

Fluid Supply Line Accessories

Install

the following accessories in the positions shown in

the T

ypical Installation, using adapters as necessary:

A check valve (F) prevents backflow into the pump

when

the pump is shut of

f.

A surge tank (H) with fluid filter reduces line pulsa-

tions

and filters the fluid.

A

fluid drain valve

(G)

is required in your system to

relieve fluid pressure in the hose and gun (see the

WARNING

at left).

When dropping down to each gun station, install a

fluid shutoff valve (J) to isolate the station during

maintenance

and repair

.

Install

a

fluid pressure

regulator (K)

for precise con

-

trol

of pressure to the

gun (L).

Fluid Return Line Accessories

Install

the following accessories in the positions shown in

the T

ypical Installation, using adapters as necessary:

Install

a

back pressure regulator (M)

after each gun

station to maintain constant back pressure in the sys

-

tem.

Install a shutoff valve (J) after each back pressure

regulator to isolate the station for repair and mainte-

nance.

Pump Intake and Suction Line

In

a circulating system such as that shown in the

T

ypical

Installation,

remove the intake elbow (8) supplied with the

pump

and replace it with an intake manifold. Install a

di-

rector

valve (N)

in the intake manifold.

Connect the fluid

return line to the director valve. Connect a drain back

tube

(S) to the branch of the director valve.

Connect

the

suction hose (P)

to the pump intake or the

intake

manifold. The

suction tube (Q)

should rest 1/2 in.

(13 mm) of

f the bottom of the supply container

.