5

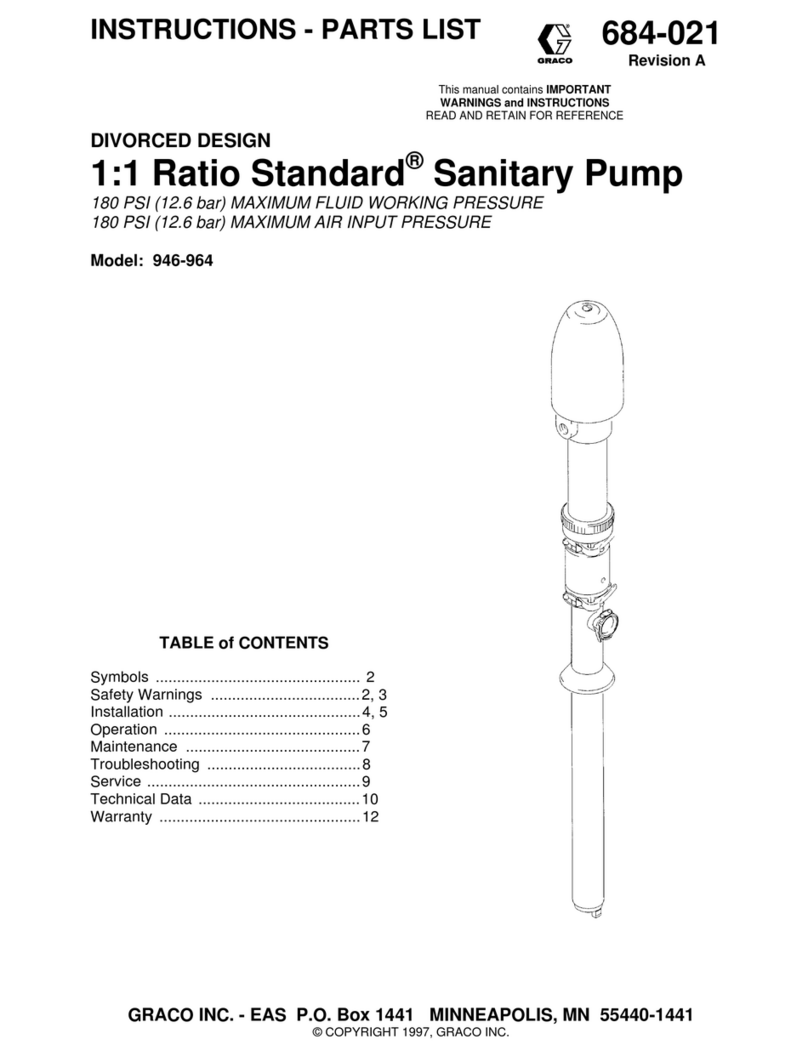

INSTALLATION

NOTE: The

T

ypical Installation on page 4 is

only a guide

to selecting and installing system components.

Your installation will depend on the type of fluid

being

pumped and your application needs. Con

-

tact

your Graco distributor for system design

as

-

sistance.

The

accessories mentioned in the text are avail

-

able

from Graco. See page 20.

Reference numbers and letters in parentheses

in

the text refer to the callouts on the drawings.

Mount the pump to suit the type of installation planned.

Be

sure the pump is securely bolted to its mounting.

If mounting the pump

on a wall, you must reposition the

legs so the pump will be upright. Remove the long bolts

(3, or 55 on models), nuts (15) and washers (16)

holding

the legs (12, 13) in place. Remove two short bolts

(14, or 3 on models), nuts (15) and washers (16)

from

each diaphragm cover (1

1).

Align

the legs with these vacant holes and reinstall using

the long bolts, washers, and nuts. Reinstall the short

bolts in the holes vacated by the legs. T orque the bolts

oppositely

and evenly

, to 13.5–16 N.m (9.8–12 ft–lb).

On

models, torque the long bolts (55)

to 13.5–16 N.m

(9.8–12 ft–lb); torque the short bolts (3) to 27 N.m (20 ft–

lb).

See Detail C in Fig. 2 and the

Mounting Diagram on

page

21.

Screw

an air control valve (P) and adapter

into the pump

air

inlet (G). W

orking upstream from the air control valve

(P),

first install an air line

lubricator (E), for automatic lu

-

brication

of the air director valve assembly

. Next, install a

bleed–type master air valve (A), an air regulator (D) to

control

pump speed and fluid pressure, and an

air line fil

-

ter

(B) to remove harmful dirt

and moisture from the com

-

pressed air supply. Install another bleed–type air valve

(A)

to isolate the accessories for servicing.

WARNING

A

bleed–type master air valve (A) is required in your

system

to relieve air trapped between this valve and

the pump after the air regulator is closed. Trapped

air can cause the pump to cycle unexpectedly,

which

could result in serious bodily injury

, including

splashing in the eyes, injury from moving parts, or

contamination

from toxic fluids.

Connect

a

grounded

air supply hose

(F) to the air control

valve

(P). The hose must be at least 6 mm (1/4 in.) ID.

The fluid connections are 1 in. npt(f). Connect a

grounded

transfer hose (J) to the pump fluid outlet (K).

Connect a fluid suction hose (L) to the pump fluid inlet

(M).

Be sure the fluid connections are tight to avoid leaks.

NOTE: Do

not pressure feed the pump. The ball checks

will

not function and the pump will not operate.

NOTE: The inlet and outlet manifolds can be removed

and turned 180 _ to change the direction the

ports face. Refer to Repairing the Check

Valves

on page 1

1 for the procedure.

Dual Inlet Conversion Kit 220–986

Order Conversion Kit 220–986 to convert Pump Model

218–940

to a dual inlet design, allowing you to pump

and

mix two fluids in a 1:1 ratio. Each of the two diaphragm

chambers

pumps one of the

fluids, and the common out

-

let aids the mixing process. However since the two dia-

phragms

pump alternately

, additional plumbing is

neces

-

sary

to ensure complete mixing.

The

outlet line should be at least 1 in. diameter tubing or

3/4

in. pipe. Runs shorter than 45 m (150 ft) should use a

100

mm (4 in.) diameter x 0.9 m (36 in.) mixing chamber

fabricated

of schedule 40 pipe.

The

inlet plumbing and suction lift

to the dual inlet pump

must

meet certain specifications so the volume of the two

fluids supplied to the pump remains equal, to ensure

proper 1:1 proportioning. The inlet lines must be the

same diameter and length, with the same number of

bends or elbows. The lift requirements of the two inlets

can vary within a range of 0.45 m (18 in.). Use a float

valve

set

at the 0.45 m (18 in.) level of one of the fluid sup

-

ply

tanks to ensure that the lift requirement is maintained.

Stainless

Steel Ball Conversion Kit 220–987

High

density fluids may keep the check balls from seating

and

the pump will not operate. The heavier stainless steel

balls

supplied in Conversion

Kit 220–987 will seat when

you

are pumping these fluids.

Air Exhaust V

entilation

WARNING

Be

sure to read and follow the warnings and

precau

-

tions regarding TOXIC FLUID HAZARD and FIRE

OR

EXPLOSION HAZARD

on page 2, before oper

-

ating

this pump.

Be sure the system is properly ventilated for your

type

of installation.

If

you are pumping

flammable, hazardous or toxic flu

-

ids, operating the pump submersed, or operating the

pump in an enclosed area, position the pump so as to

avoid

exhausting

air toward people; the exhaust air must

be vented to a safe area, away from all people. Y ou

MUST use a grounded air hose (see “ Grounding” be-

low). The exhaust line should end in a container which

can catch any fluid that would be exhausted if a dia-

phragm

ruptured. See Detail A,

Fig. 2, and the

ACCES-

SORIES section on page 20 to order the necessary

plumbing.

Grounding

WARNING

This

pump must be grounded. Be sure to read and

follow

the

warnings and precautions regarding

FIRE

OR

EXPLOSION HAZARD

on page 2 before oper

-

ating

this pump.

To reduce the risk of static charge build–up on the

muffler which can cause static sparking, the ex-

haust

line

MUST

be a grounded air hose.