Section 3: Installation Page 9

3.1 GENERAL

Installation of this pump station must be carried out by a

competent installer in compliance with all current local Building

Regulations, codes of practice, Health & Safety legislation and

any relevant bylaws and regulations in force at the time.

electrician. The electrical installation must comply with the

requirements of the Electricity at Work Regulations 1989 and

BS7671:2008 - IET Wiring Regulations 17th Edition British

Standards Institutions (including all amendments).

3.2 REGULATIONS AND STANDARDS

The installation of the Grant Solar Pump Station must be in

accordance with the following recommendations, as applicable:

• Building Regulations for England and Wales, and Building

Standards for Scotland

• Local Bylaws (check with the Local Authority for the area)

• Water Supply (Water Fittings) Regulations 1999

The installation should also be in accordance with the latest

• BS7671 and amendments

• BS EN 12831

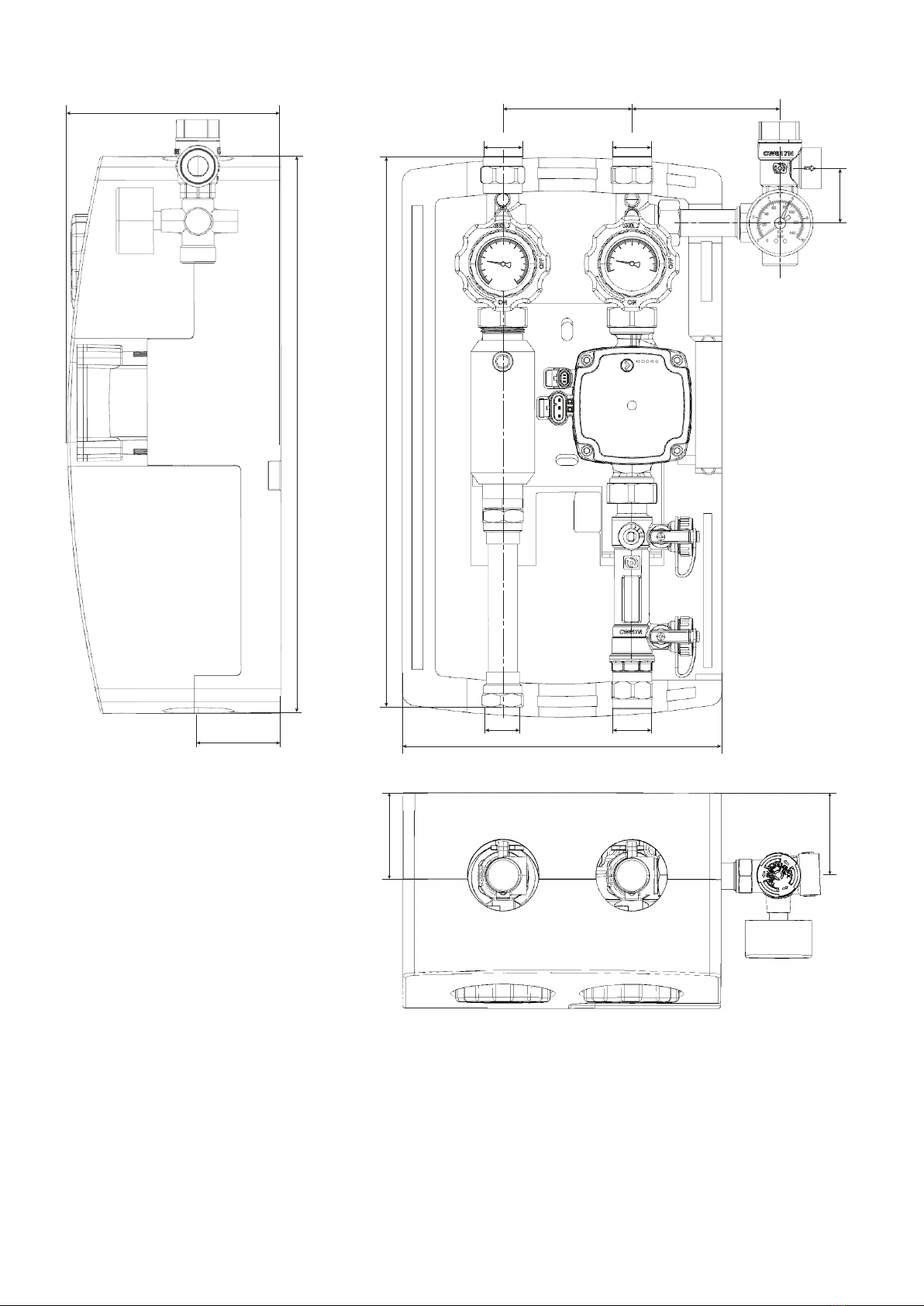

3.3 LOCATION

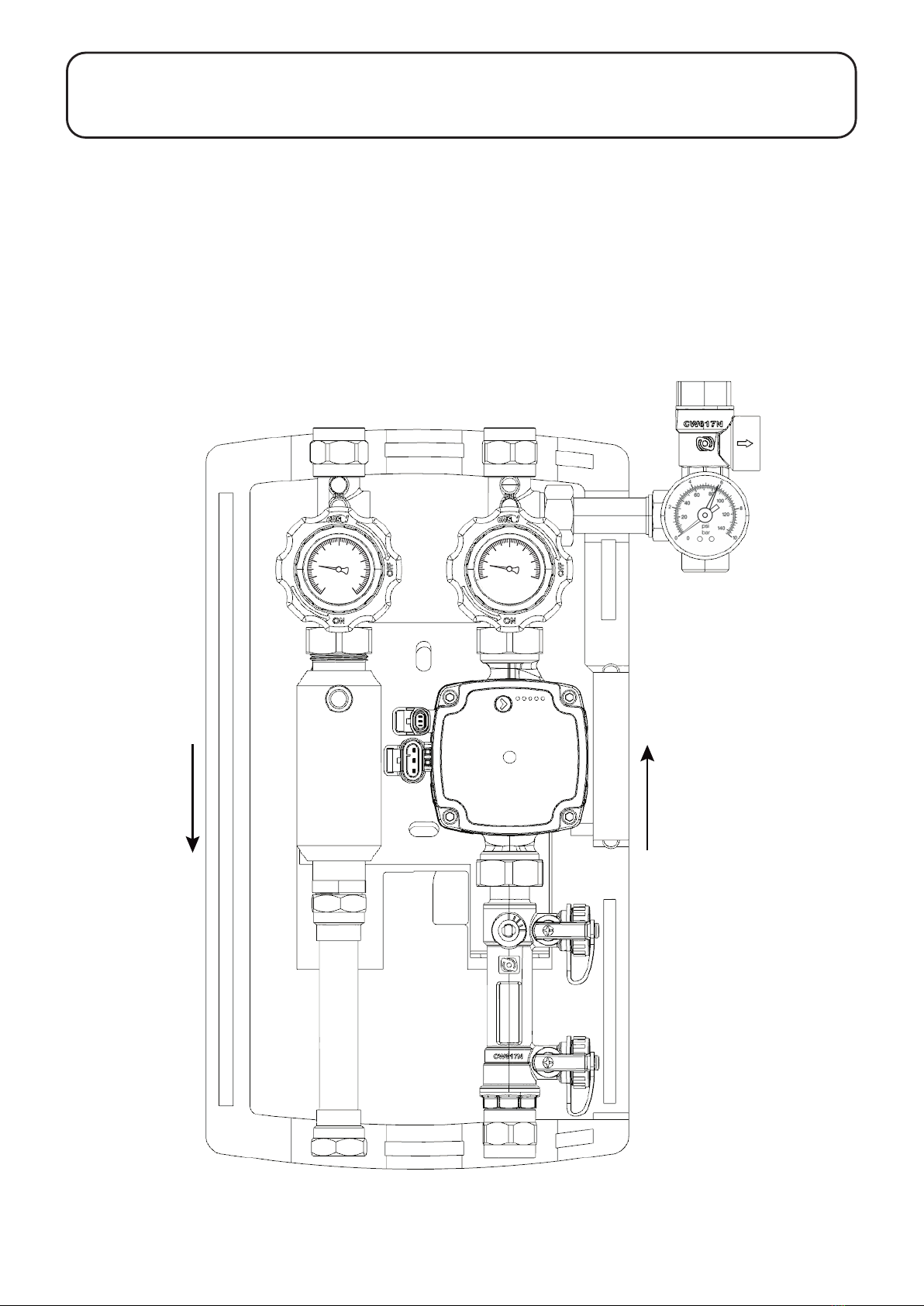

The Grant Solar Pump Station can be mounted on any suitable

wall surface capable of carrying the weight of the Grant Solar

Pump Station (refer to Table 2-1) where the required clearances

can be achieved. Leave at least 20 cm at each side of the Grant

Solar Pump Station.

Before mounting of the Grant Solar Pump Station an installation

damage to the elements of the Grant Solar Pump Station. The

pump group is designed for wall mounting in an upright position.

The Grant Solar Pump Station MUST only be installed inside

a property, and not located externally, as it not designed to be

weatherproof.

3.4 SAFETY

The Grant Solar Pump Station is intended only for closed solar

installation. The Grant Solar Pump Station complies with the

current technical standards and technical safety regulations.

Each device is checked for proper operation and safety prior to

shipping.

The Grant Solar Pump Station MUST only be installed and

operated by trained personnel. Untrained personnel can work only

under the supervision of an experienced person, who is familiar

with the way the unit works. Before installation, the installer must

carefully read and understand these instructions.

! WARNING !

The temperature inside the Grant Solar Pump Station can

reach dangerous temperatures that can cause serious

burns.

! WARNING !

Ensure that the electrical supply has been isolated before

making any wiring connections.

3 INSTALLATION

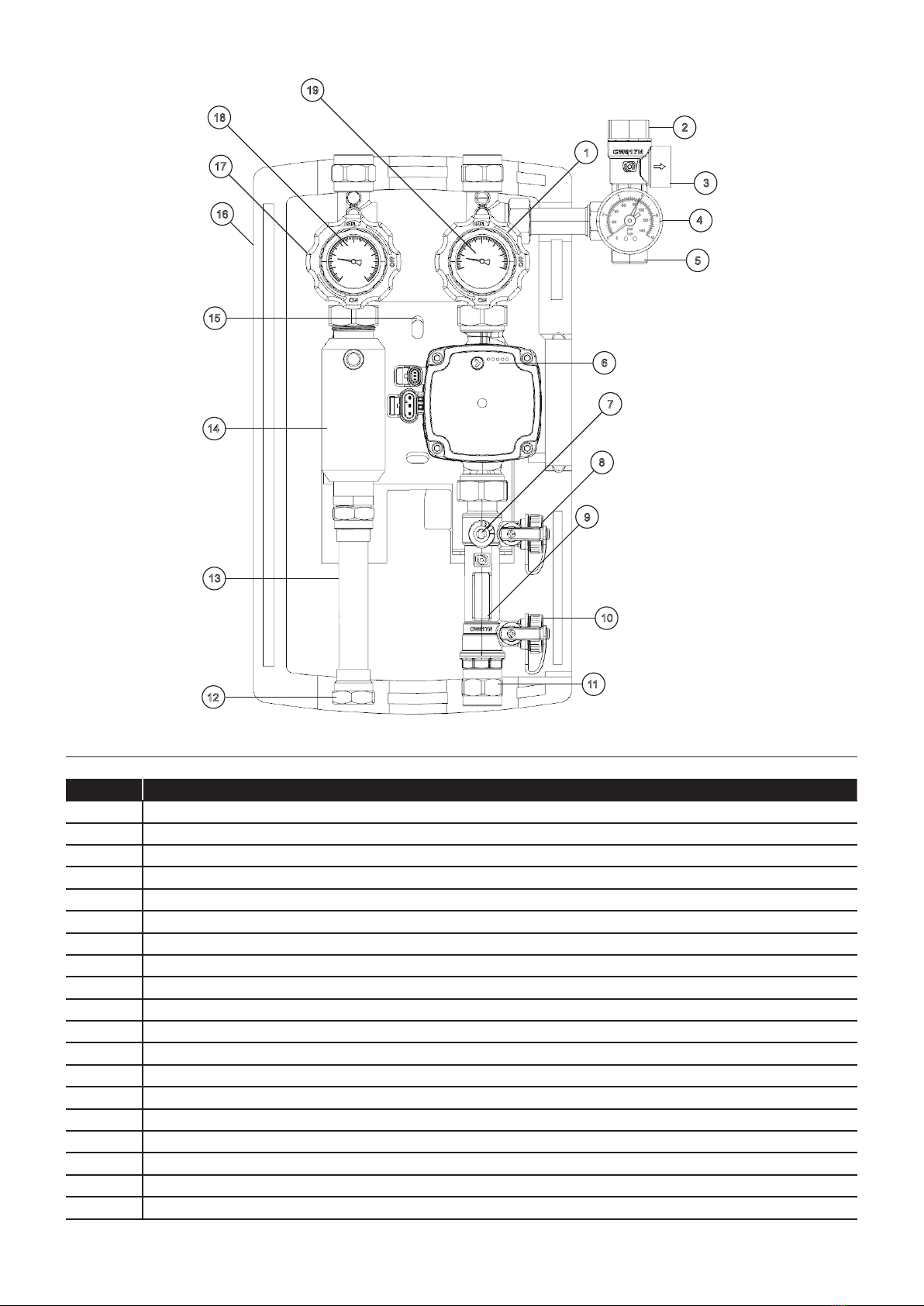

3.5 FITTING PROCEDURE

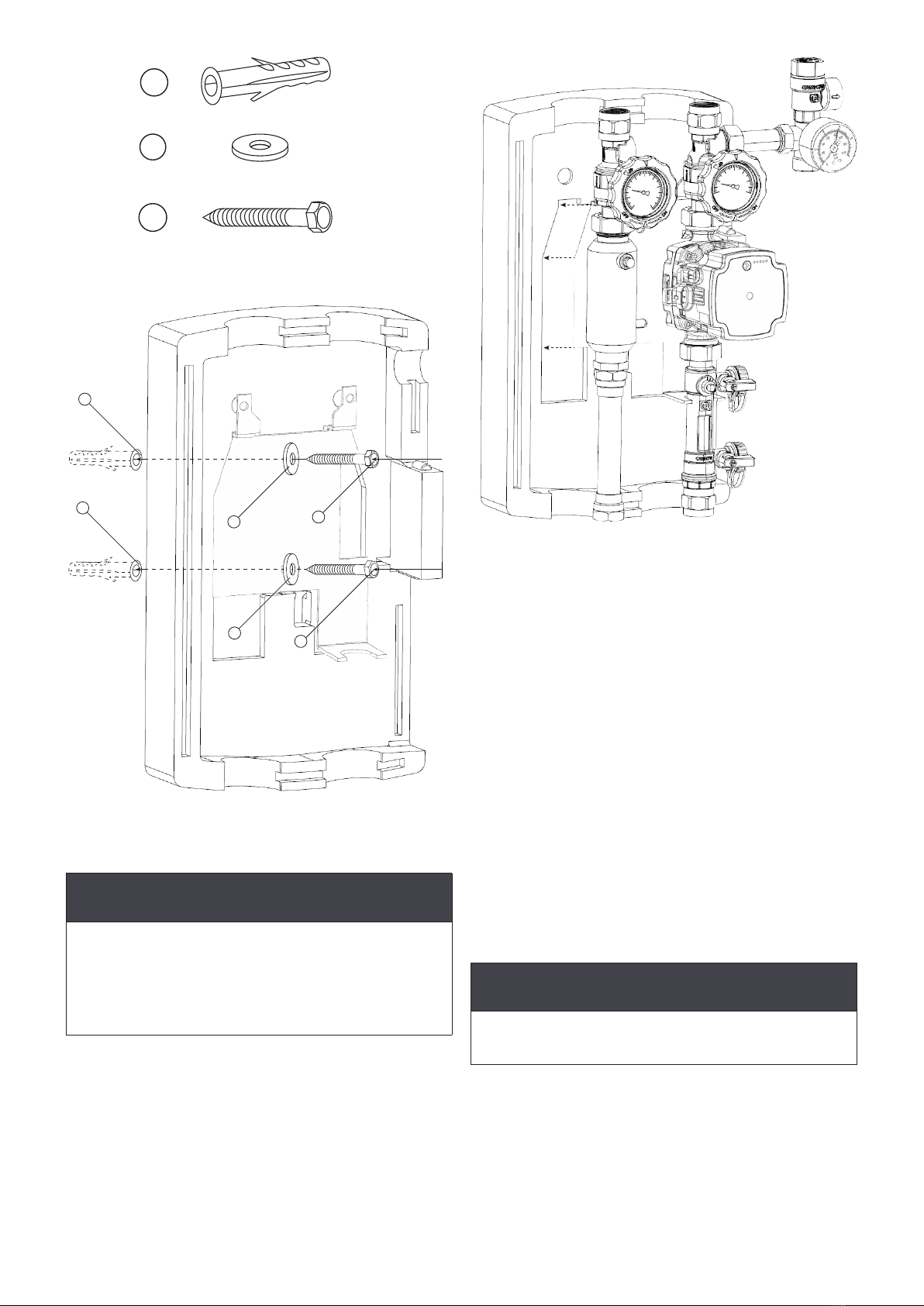

1. Refer to Figure 3-1. Take the two coach screws (3), the two

plugs (1) and the two metallic washers (2) from the wall

bracket kit

2. Remove the front section of the insulated pump station

housing

3.

4. Position the back section of the insulated housing in the

required location. If necessary check the cover is level using

a spirit level on the side and mark the top hole of the wall

bracket.

5.

set into the marked hole with a 10 mm drill bit.

6. Position the back section of the insulated housing in the

(3). Refer to Figure 3-2.

! CAUTION !

When xing the coach screw in step 6 proceed carefully.

The insulation is not rigid and overtightening the screw

could damage it.

7. Mark the position of the lower hole of the wall bracket on the

wall.

8. Remove the coach screw and carefully lift the back section of

the insulated housing

9.

pump set into the marked hole with a 10 mm drill bit

10. Fit

section of the insulated housing taking care to insert it

completely. Refer to Figure 3-3.

11. Lift the back section of the insulated housing and the wall

the two coach screws (3) and the two metallic washers (2).

Place the washers on the outside of the bracket mounting

holes, as shown in Figure 3-2.

! NOTE !

The Grant Solar Pump Station MUST only be installed

vertically, as shown in Figure 1-1.