The GPI HP-90 Petroleum Hand Pump is designed to manu-

ally pump petroleum products such as diesel fuel, kero-

sene and gasoline and fits any container with a 2-inch NPT

bung.

Construction: Lightweight aluminum housing, stain-

less steel shaft and plastic piston

Capacity: Up to 1 quart per stroke

Inlet Port: 1 inch NPT

Inlet Screen: Integral with pump

Outlet Port: 3/4 inch NPT

Hose and Nozzle: 3/4 inch x 8 foot Buna-N hose. Ther-

moplastic unleaded nozzle

Suction Pipe: 2 piece PVC

Shipping Weight: 12.8 pounds (5.8 kg)

SPECIFICATIONS

TROUBLESHOOTING

OPERATIONS

Observe safety precautions when handling fuel:

•

Keep fuel away from open flame or spark.

•

Do not refuel vehicles or equipment with engines run-

ning or while engine is hot.

•

Do not smoke while refueling.

•

Know and follow all safety precautions when handling

petroleum fluids

•

Insure that all equipment operators have access to ad-

equate instructions concerning safe operating and main-

tenance procedures.

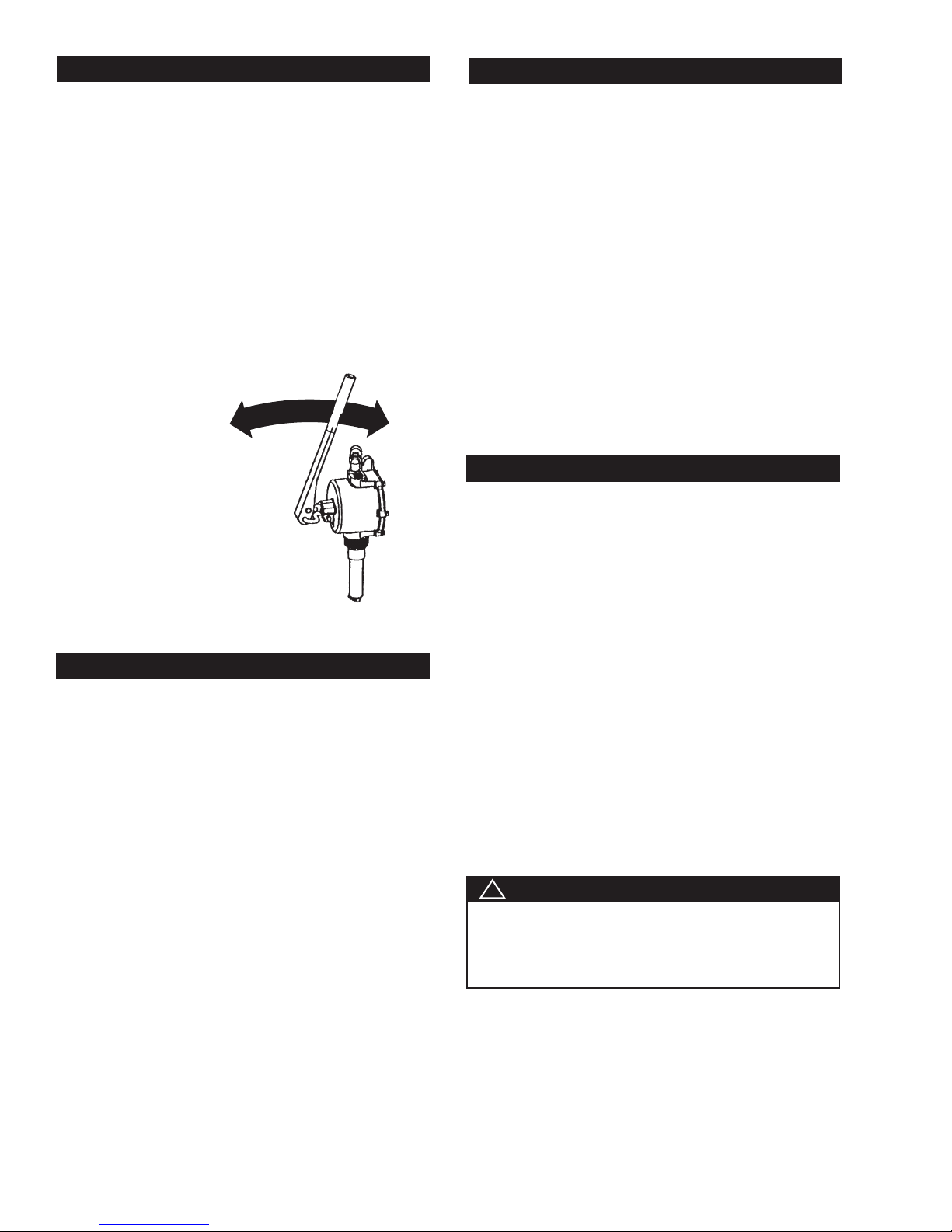

To Dispense Fluid

1. Remove the nozzle from its holder and

insert into the receiving tank of the

equipment or vehicle.

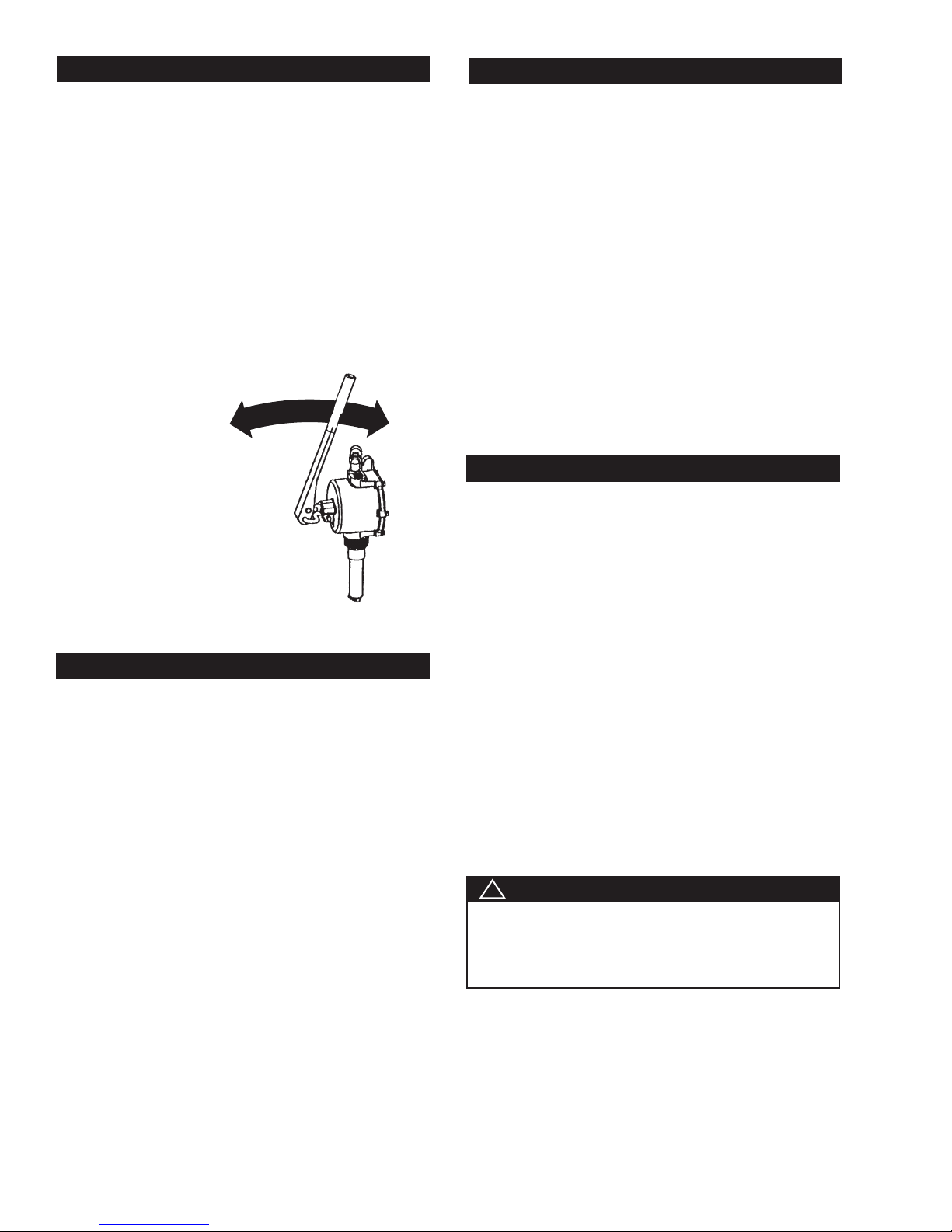

2. To pump, manually

move the handle

front to back as

shown on right.

3. Return the handle

to its upright storage

position, after dis-

pensing the desired

amount of fluid. Drain

the hose and place

the nozzle in its holder.

A. Shaft Seal Leak

1. Seal worn. Replace (Seal Kit 131501-02).

B. Anti-Siphon Vent Leak

1. Vent damaged. Remove and clean or replace

(Kit 123504-1).

C. Low Flowrate

1. Inlet screen clogged. Remove pump and suction

pipe, clean screen and re-install.

2. Suction pipe leak. Repair or replace as needed.

3. Piston seals worn. Replace (Seal Kit 131501-02).

SERVICE

For warranty consideration or other service information,

please contact your local distributor. If you need further as-

sistance, contact the GPI Customer Service Department in

Wichita, Kansas, during normal business hours. A toll free

number is provided for your convenience.

1-800-835-0113

To obtain prompt, efficient service, always be prepared with

the following information:

1. The model number of your pump.

2. The manufacturing date code of your pump.

For the HP-90, the date code is located on the shaft side of

the pump housing.

For warranty work, always be prepared with your original

sales slip or other evidence of purchase date.

Please contact GPI before returning any pump. It may be

possible to diagnose the trouble and find a solution with a

telephone call. GPI can also inform you of any special re-

quirements you will need to follow for shipping.

!

! ! ! CAUTION ! ! !

Do not return the pump without authority from the

Customer Service Department. Due to strict govern-

ment regulations, GPI cannot accept pumps unless

they have been drained and cleaned.

Front

Back