WARNING! THISISNOTA TOY!

THIS ISNOTA BEGINNER'S AIRPLANE!

This R/C kitand the model you willbuildisnot a toy!Itiscapable of serious bodily harm and

property damage ITISYOUR RESPONSIBILITY AND YOURS ALONE — to build this kit correctly, to

properly install allR/C components andflyinggear (engine, tank, pushrods, etc)and to test the model

and flyit only with experienced, competent help, using common sense and inaccordance with allsafety

standards asset down inthe Academy of Model Aeronautics Safety Code Itissuggested that you join

the AMAand become properlyinsuredbeforeyouattemptto flythismodel IFYOU AREJUST

STARTING R/C MODELING, CONSULT YOUR LOCAL HOBBY SHOPOR WRITE TO THE ACADEMY

OF MODEL AERONAUTICS TOFINDAN EXPERIENCED INSTRUCTORINYOUR AREA.

Academy of Model Aeronautics

1810 Samuel Morse Dr.

Reston,VA22090 (703)435-0750

INTRODUCTION

Congratulationsandthankyoufor

purchasing the Great Planes SUPER SKYBOLT'

The skyboltincorporatesseveralnew design

features never beforefound ina biplane kit The

revolutionarywingattachmentsystemmakes it

incredibly easy toassemble and disassemble at

the field using only a screwdriverItalso features

several new constructiontechniques that make it

the easiest and straightest building biplane ever!

The Great Planes Super Skybolt is a high

performance biplane that ismodeled after the full

size Skybolt Itnot only looks beautiful,but it is

also thesmoothestand most predictable flying

biplane we have ever flownHowever, this isnot

abeginner's airplane! While the Super Skybolt

is not difficulttobuild and fliesgreat,we must

discourageyoufromselectingthiskit as your

firstR/C airplane Itis highly maneuverable, and

lacks theself-recoverycharacteristicsof a good

basictrainersuchastheGreatPlanesPT

Series airplanes On the other hand, ifyouare

confidentwithyourflyingskilland can safely

handleaileronairplanessuchastheGreat

Planes Ultra-Sport Series or Big Stick Series,

the Super Skybolt isan excellent choice Ifyou

currentlyflyan aileronairplane,but youare

unsureabout yourabilitytohandle theSuper

Skybolt, we recommend that you buildand flya

low-wing sport plane first.

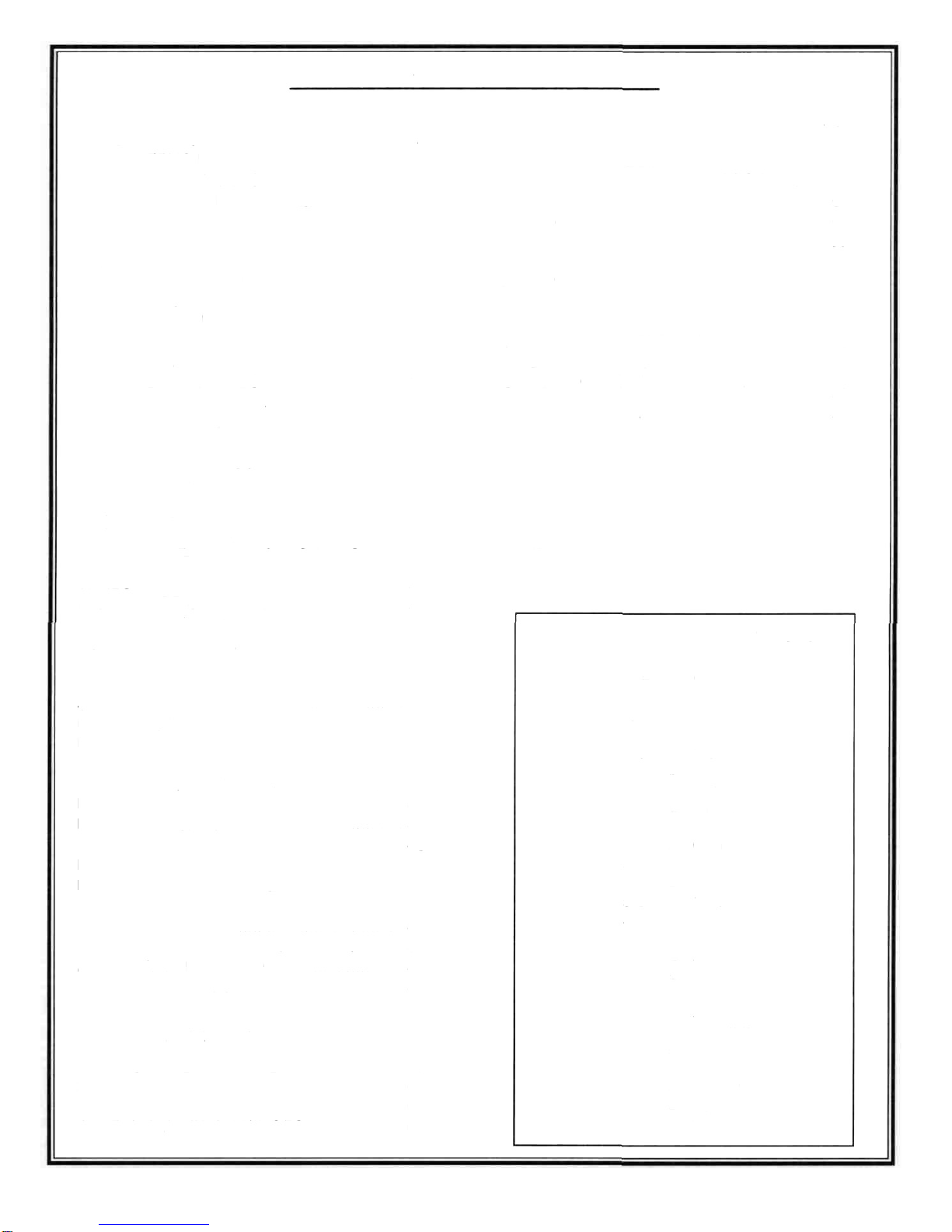

Please inspect allparts carefully before

starting to build!Ifany parts are missing,

broken or defective, or ifyou have any

questions about building or flyingthis

airplane,pleasecallusat (217) 367-2069

and we'llbe gladtohelp. If youare

callingfor replacement parts, pleaselook

up thepartnumbersandthekit

identification number (stamped on the

endof the carton) and have them ready

when calling.

PRECAUTIONS

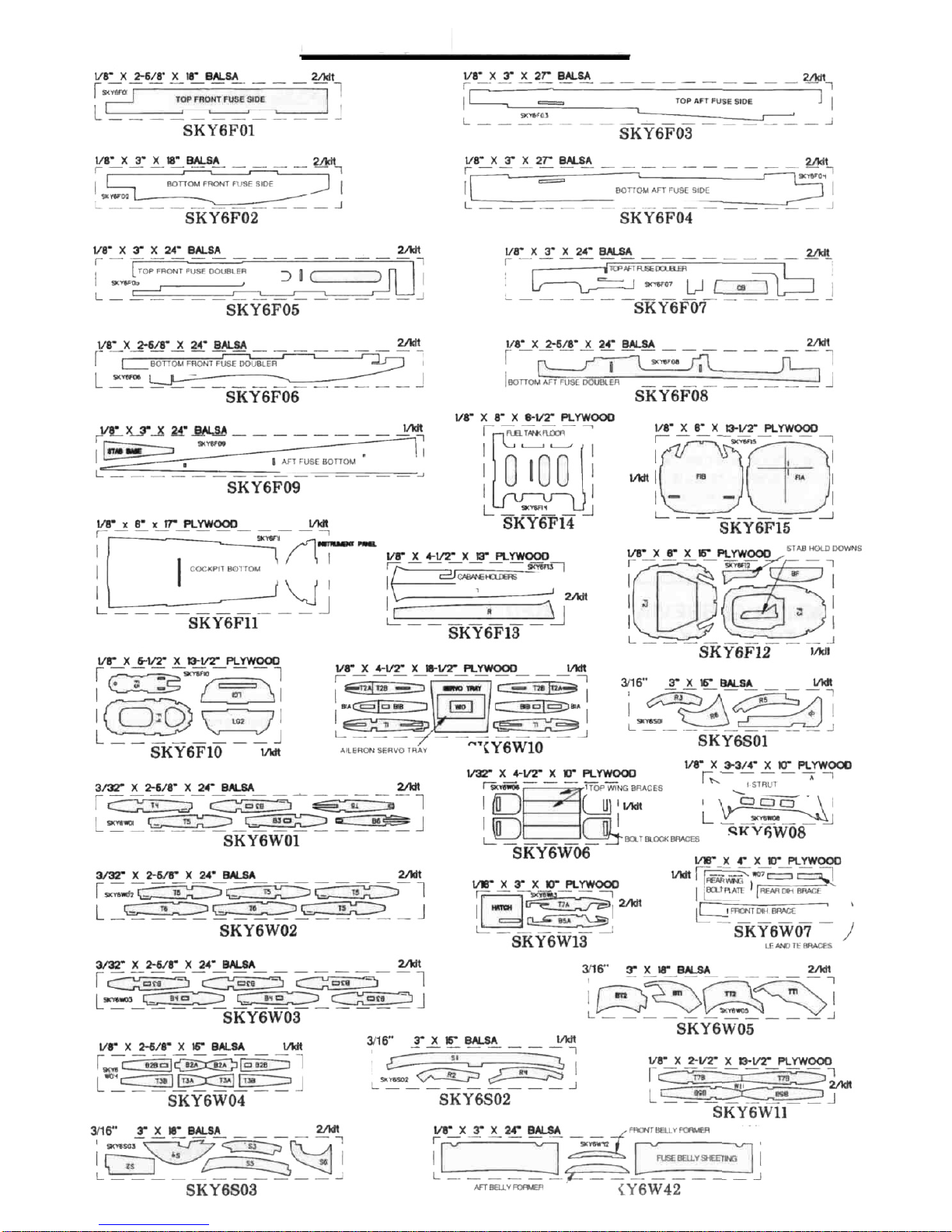

1You must build the plane according to the

plans and instructions. Do not alter or modify

the model, as doing so may result inan unsafeor

unflyablemodel Ina fewcasestheplans and

instructions may differslightly fromthe photos In

thoseinstancesyoushouldassumetheplans

and writteninstructionsarecorrectAlso,you

may notice a slight differenceinlength between

longer parts and the plans This isnormal and is

caused by the plans expanding and shrinking with

the changing moisturecontent inthe air Donot

modify the parts to fitthe plan

2You musttake time to buildstraight, true and

strongIMPORTANT- Glueshouldneverbe

substitutedfora good-fittingjointTake a little

extratime toget a good fittingjointand glue it

properlyItwillbe stronger,neater,and much

lighter than a bad joint heldtogether with a glob

of glue!

3-