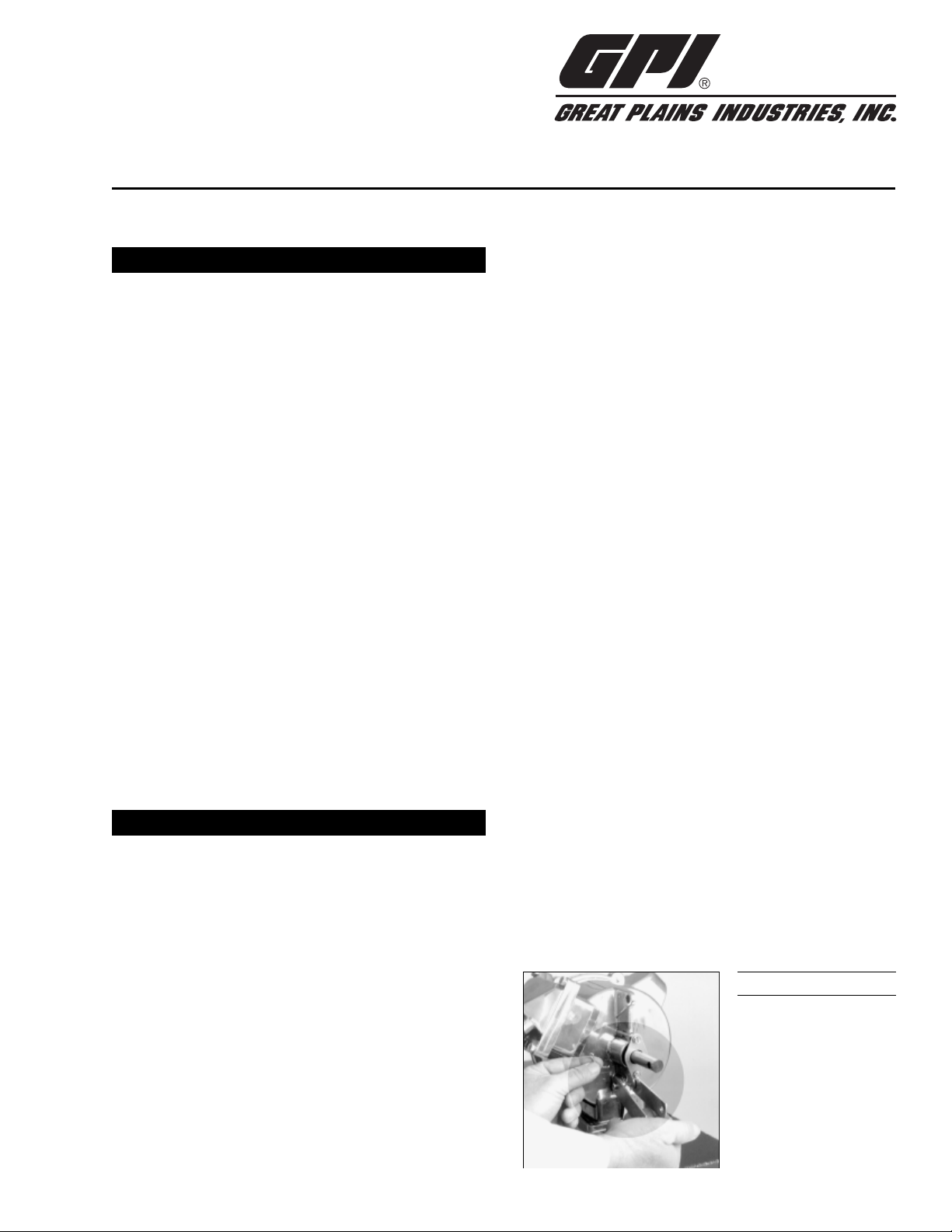

The HP-100 DUAL-FLO

®

Petroleum Hand Pump is compat-

ible with a wide variety of petroleum products and fits any

container with a 2-inch NPT bung.

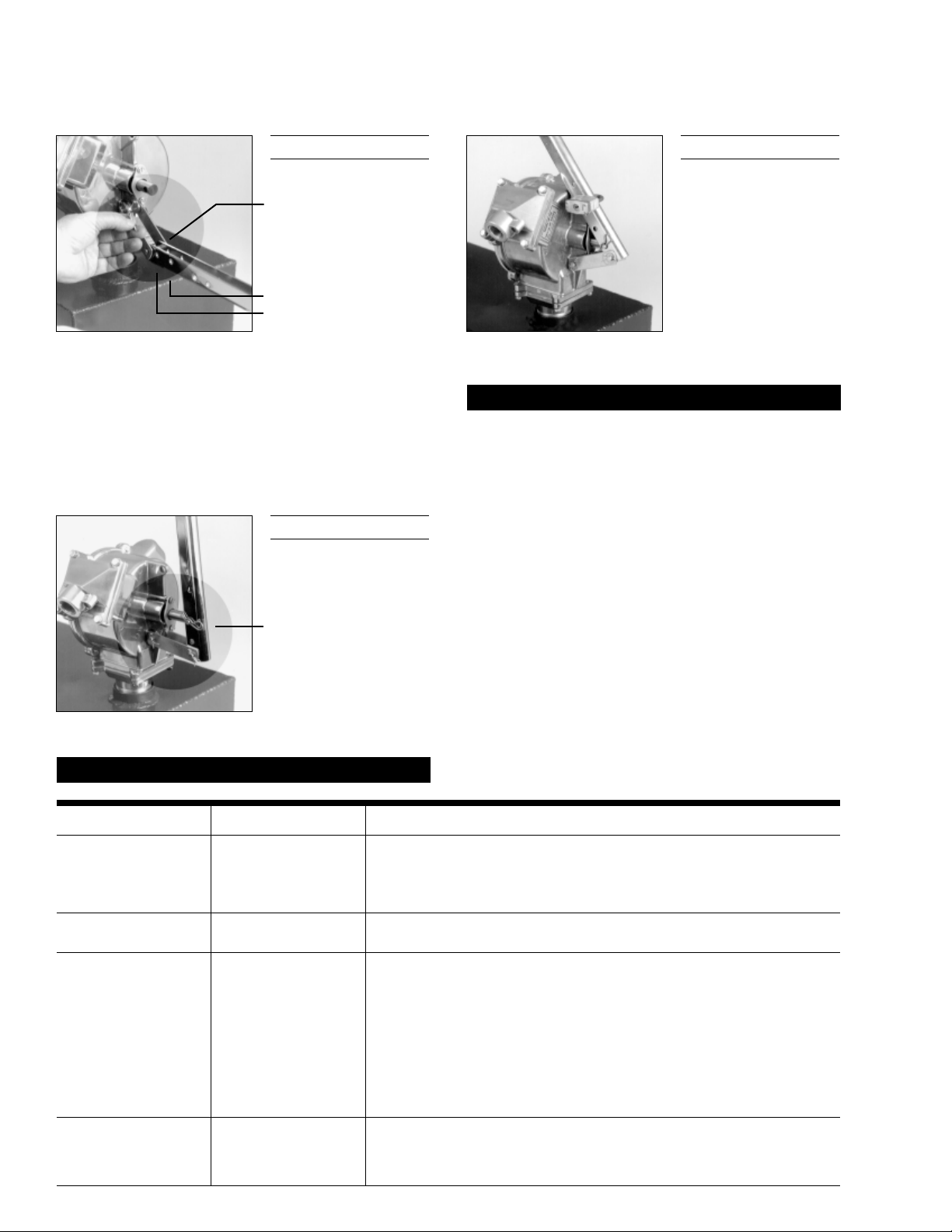

Construction Lightweight, die-cast aluminum hous-

ing. Stainless steel piston shaft and

liner. Buna-N seals. Built-in air valve to

prevent leakage at the nozzle.

Pumping Capacity 1/2 gallon (1.9 litres) per stroke cycle.

Pumping Settings 1/2 gallon setting for high volume, high

resistance.

1/4 gallon setting for low volume, low

resistance.

Inlet Standard 1-inch NPT pipe.

Outlet Standard 3/4-inch NPT pipe.

Shipping Weight 14 lbs.

Hose and Nozzle 3/4 inch x 8 foot Buna-N hose. Thermo-

plastic unleaded nozzle. Built-in nozzle

holder.

Suction Pipe Plastic, adjustable 22 to 40 inches.

For warranty consideration, parts or other service informa-

tion, please contact your local distributor or the GPI Cus-

tomer Service Department in Wichita, Kansas, during normal

business hours.

1-800-835-0113

To obtain prompt, efficient service, be prepared with the

following information:

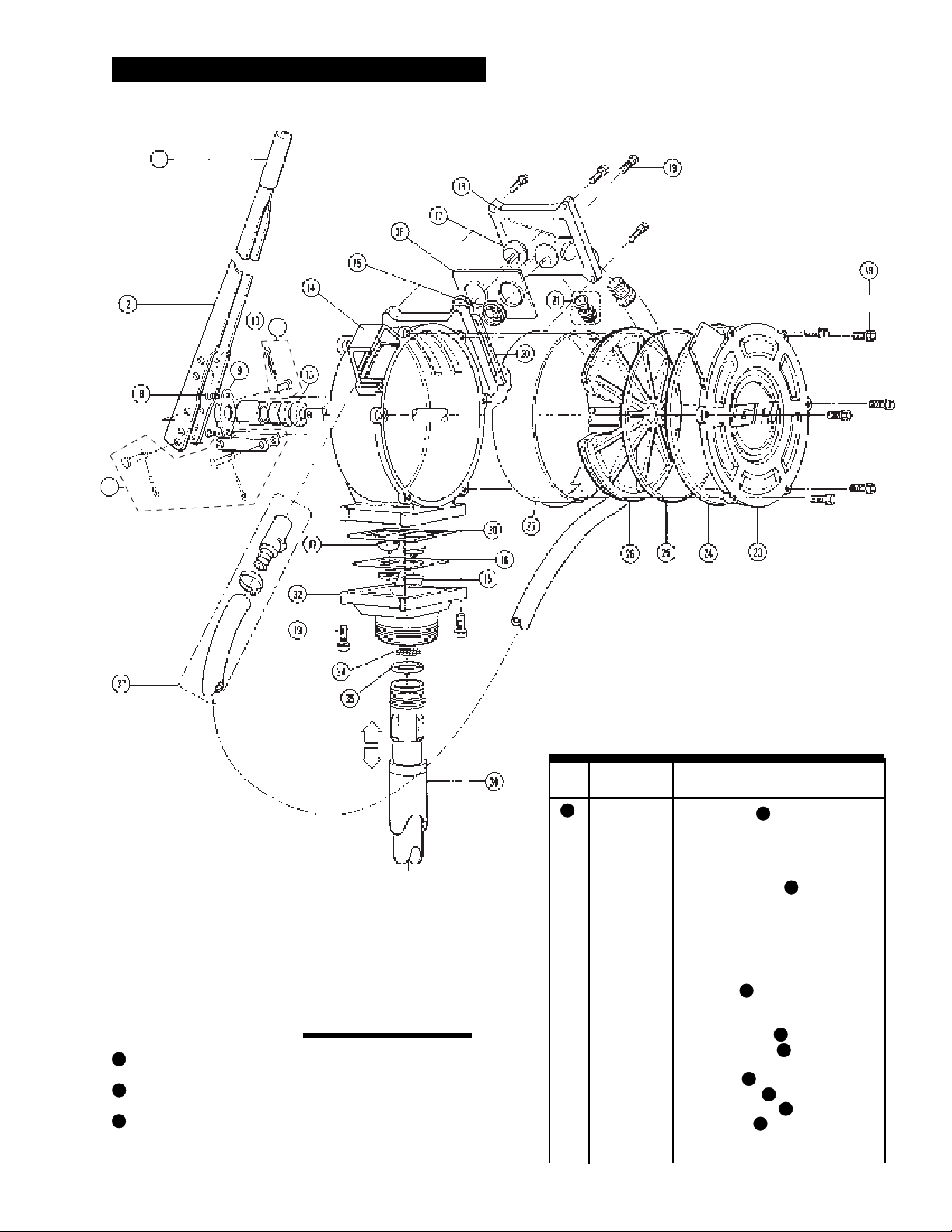

•The model number of your pump.

•The manufacturing date of your pump.

•Part descriptions and numbers.

Part descriptions and numbers can be obtained from the

Illustrated Parts Drawing.

For warranty service, be prepared with your original sales slip

or other evidence of purchase date.

U.S. Patent D 308,567

Dual-Flo and GPI are registered trademarks of

Great Plains Industries, Inc.

© 2002 by GREAT PLAINS INDUSTRIES, INC., Wichita, KS

Printed in U.S.A.

SPECIFICATIONS PARTS AND SERVICE

5252 East 36th Street North

Wichita, KS USA 67220-3205

TEL: 316-686-7361

FAX: 316-686-6746

“A Great Plains Ventures Subsidiary”

www.gpi.net

1-800-835-0113

Rev. - 921407-0911/02

Limited Warranty Policy

GreatPlains Industries,Inc.5252 E.36

th

Street North,Wichita,KS USA67220-3205,hereby providesalimited twoyearwarranty against

defects in material and workmanship on all products manufactured by Great Plains Industries, Inc. except models BP-10, BP-12, CP-5,

D-12, D-24, D-115, D-230, LP-50 and RP-5. These models carry a 90-day warranty. The warranty shall extend to the purchaser of this

product and to any person to whom such product is transferred during the warranty period.

The warranty period shall begin on the date of the original new equipment purchase. Warrantor’s obligation hereunder shall be limited to

repairing defective workmanship or replacing or repairing any defective part or parts. This warranty shall not apply if:

A. the product has been altered or modified outside the warrantor’s duly appointed representative;

B. theproducthas beensubjectedtoneglect, misuse,abuseordamage or hasbeeninstalledor operatedotherthanin accordance

with the manufacturer’s operating instructions.

To make a claim against this warranty, notice of claim must be given in writing to the company at its above address no later than 30 days

aftertheexpirationofthe warranty period.Suchnoticeshallidentifythedefectin theproduct.Thecompanyshall,within14daysof receipt

of such notice, notify the customer to either send the product, transportation prepaid, to the company at its office in Wichita, Kansas, or

to duly authorized service center. The company shall perform all obligations imposed on it by the terms of this warranty within 60 days of

receipt of the defective product.

GREAT PLAINS INDUSTRIES, INC. EXCLUDES LIABILITY UNDER THIS WARRANTY FOR DIRECT, INDIRECT, INCIDENTAL AND

CONSEQUENTIAL DAMAGES INCURRED IN THE USE OR LOSS OF USE OF THE PRODUCT WARRANTED HEREUNDER.

Thecompanyherewithexpresslydisclaimsany warranty ofmerchantabilityorfitnessforanyparticularpurposeotherthan for whichitwas

designed.

This warranty gives you specific rights and you may also have other rights which vary from U.S. state to U.S. state.

Note: In compliance with MAGNUSON MOSS CONSUMER WARRANTY ACT – Part 702 (governs the resale availability of the warranty

terms).