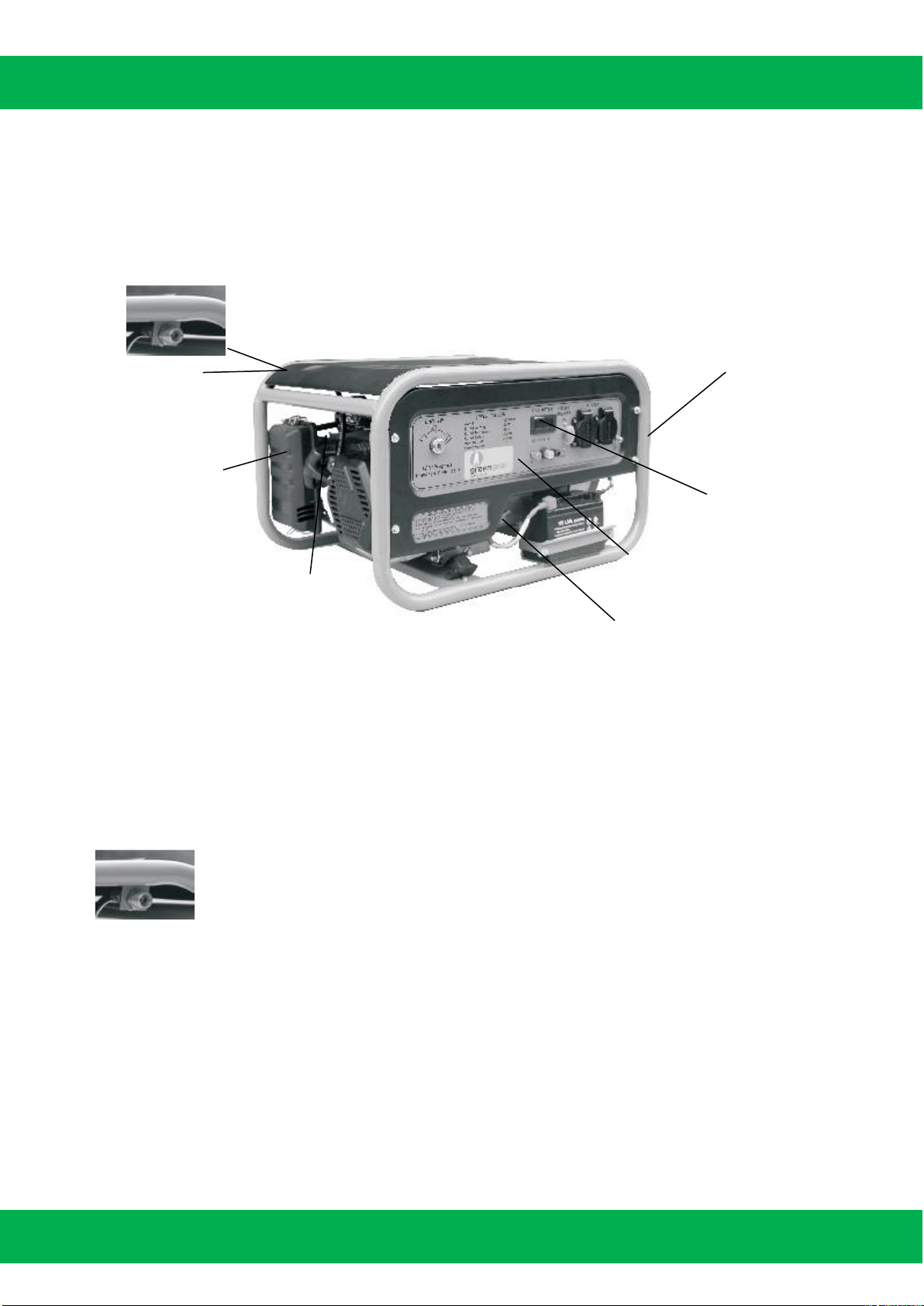

GENERATOR MANUAL

6

SAFETY PRECAUTION

Preparation

Before use, remove any plastic bags and all packaging materials and keep them out of children’s

reach.

Inspect the Equipment before use. Report any missing components and replace damaged parts.

Do not operate the unit with loose or damaged parts.

Operation

Use this Equipment only for its intended purpose. Its use for others purpose is not permitted and

may be dangerous or result in damage to the Machine.

Do not operate the engine in a confined space where dangerous carbon monoxide fumes can collect;

Do not change the engine governor settings or over speed the engine;

Start the engine carefully according to instructions

Do not tilt the equipment when starting the engine;

Do not touch wires while engine is running: electrical shock can cause injury.

Maintenance and storage

Keep all nuts, bolts and screws tight to be sure the equipment are in safe working condition;

Never store the equipment with LPG/PROPANE cylinder inside a building where fumes can reach

an open flame or spark. Never leave in direct sunlight. Never store at temperature above 49 °C

(120 degrees F°).

Exhaust contains poisonous carbon monoxide gas that can build up to dangerous levels in closed

areas. Breathing carbon monoxide can cause unconsciousness or death.

Allow the engine to cool before storing in any enclosure: hot parts can cause severe burns.

Replace worn or damaged parts for safety;

Always keep warning and information stickers clean and readable.

WARNING

GREENGEAR GLOBAL SRL assumes no liability for material or personal damage caused by the non-

observance of information contained in the operator’s manual, in particular in regard to safety, operation

and maintenance, or which arise through the use of unauthorized attachment or spare parts. Any damage

caused by non-compliance with the safety, operating and maintenance instructions is the sole

responsibility of the user.

GREENGEAR GLOBAL SRL also reserves the right to modify the description in this instruction manual at

any time and without prior notice. Reproduction, transmission or translation into another language

partially in any form of this manual is absolutely forbidden without prior written consent by GREENGEAR

GLOBAL SRL.

WARNING Read this manual carefully.

WARNING Do not operate the generator near stored petrol or gaseous

fuel.

WARNING LPG/PROPANE is highly flammable, and its vapors can explode if ignited.