12 Manual Chipper GTS 1300

13

Manual Chipper GTS 1300

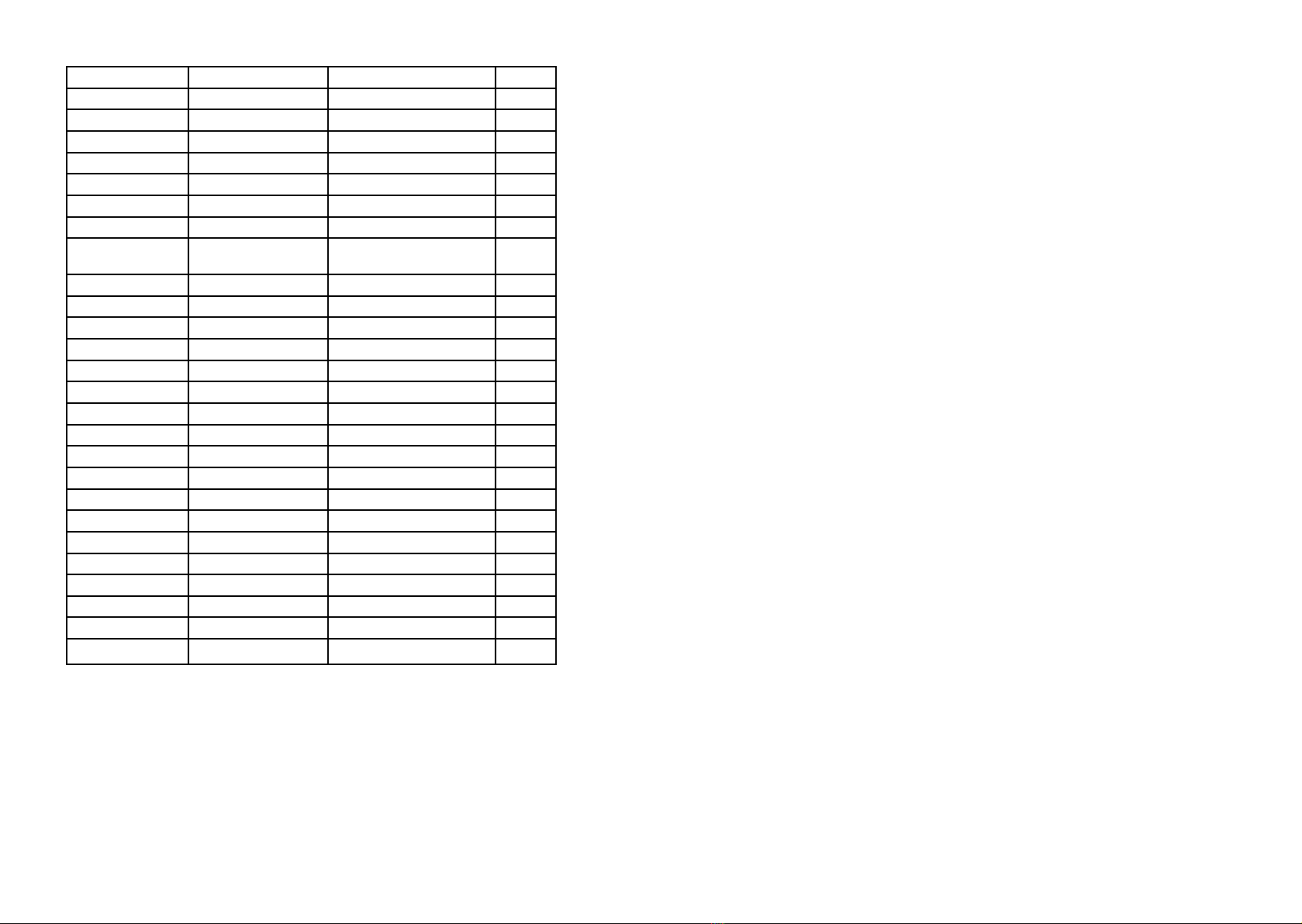

PROBLEMS & SOLUTIONS

Problem Cause Solution

The shredder does not

perform properly: the

wood is not pulled in

by the machine itself.

The chips do not have

the same size.

-The blades are worn too

much

-The diameter of the

branches inserted into

the machine is too large

-There is too big a gap

betweenthexedblade

and the counter blade:

correct gap is 0.5 mm

(halfamillimetre)

-Change or sharpen the blades

and counter-blade. Note that the

blades are sharpened on both

edges so they can be reversed.

-Shut the engine off and remove

the branch that is too thick

-Adjustthegapbetweentheblade

and the counter-blade by moving

the counter-blade in the slots

The engine does not

start/ the engine shuts

off by itself

-Electrical problem with

the engine

-No fuel

-No or not enough oil in

theengine(theoilshould

be level with the threads

ofthellerhole.)

Check that

-Theinputtubeiscorrectlytted

and the bolts are tight

-Put the start-switch of the engine

“On”

-De-activate the emergency switch

(turntheknob)

-Check oil and fuel levels

-Contact your dealer

Important : Tighten the blade bolts

usingatorquewrench;70Nmfor

the blades on the rotor and 40Nm

for the counter blade. Fix with

Loctite 243.

Therotorjams

The engine will not

start/turn because the

rotorisjammed.

-the diameter of the

branch is too big

-there are unacceptable

materials such as stones

or metal in the input tube

-a length of branch

remains in the rotor

after the engine was last

stopped.

-shut off the engine, remove the

spark plug cap and turn the

rotorcounter-clock-wise.Usea

wooden stick to turn the rotor and

to remove the material from the

rotor and input tube.

If necessary, remove the cap of

the bearing housing and rotate the

rotor axle with a spanner.

If necessary, remove the input or

output tube to facilitate access to

the rotor.

Check the sharpeness of the

blades and counter blade and

replace them if necessary.

Important: Tighten the blade bolts

usingatorquewrench;70Nmfor

the blades on the rotor and 40Nm

for the counter blade. Fix with

Loctite 243.

4. Transport

Before moving the machine, stop the engine!

MAINTENANCE AND CHECKS

All technical check-ups and maintenance should be done with the

engine shut off and the spark plug cap removed from the spark

plug.

While cleaning the shredder, never spray the bearings with a high

pressure washer! It could cause water to enter the bearings which

willcausedamagetothemachine;(thisisnotcoveredbywarranty).

Thetwogreasenipplesontherotorrequirelubricatingonceayear

or every 500 hours.

Before putting the shredder into storage grease or oil the bearings,

blades and rotor to protect against corrosion.

For engine maintenance refer to the Engine Manufacturers Engine

Manual.

Notethattherstengineoilchangeisafter5hoursuse.