10 I EN

Read and understand all of the operating instructions, safety precautions and warnings in the Instruction

before operating or maintaining this compressor.

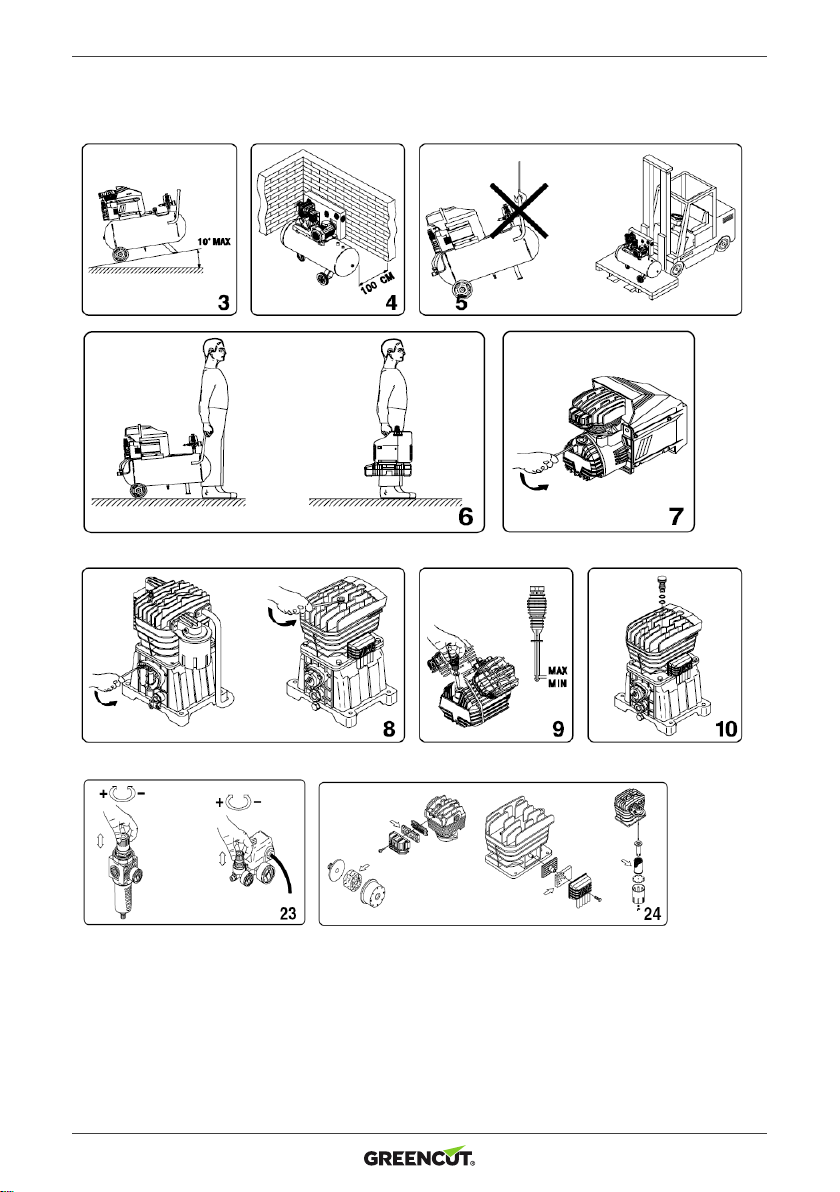

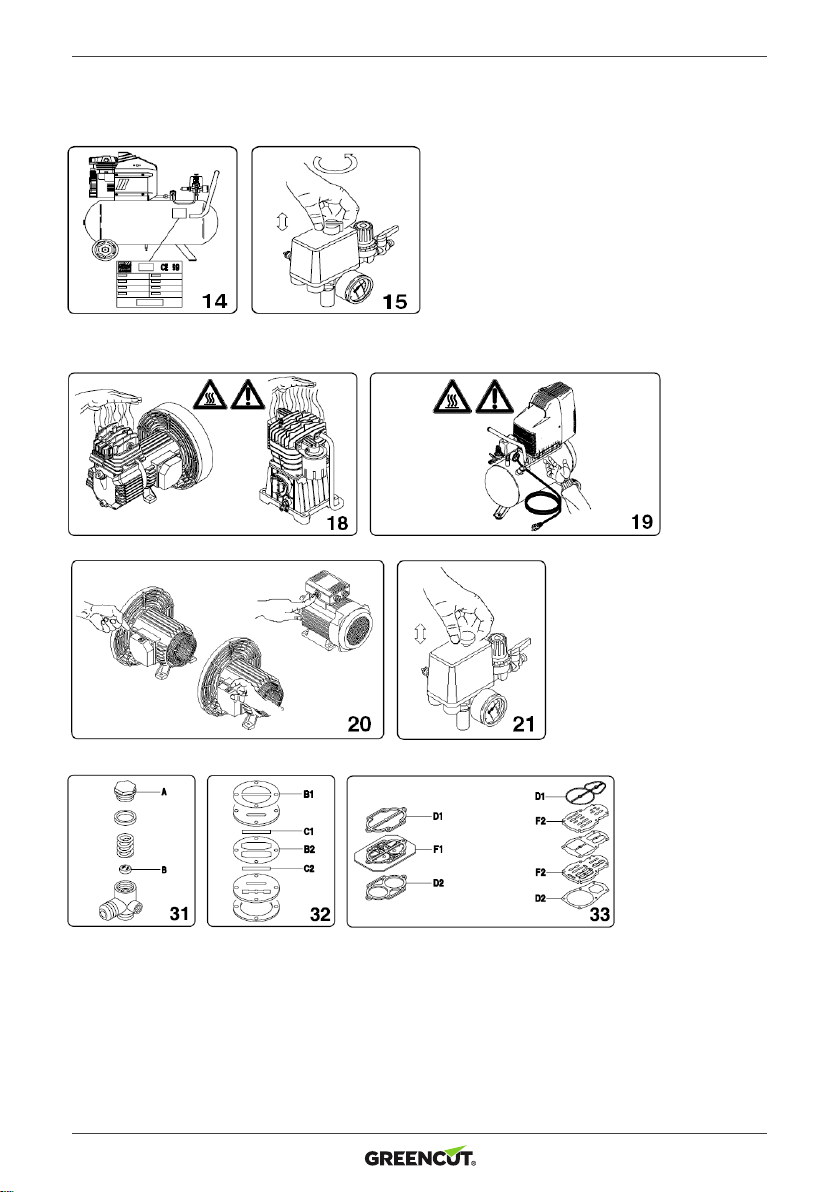

Most accidents that result from compressor operation and maintenance are caused by the failure to observe

basic safety rules or precautions.

An accident can often be avoided by recognizing a potential hazardous situation before it occurs, and by

observing appropriate safety procedures.

Basic safety precautions are outlined in the “SAFETY” section of this Instruction Manual and in the sections

which contain the operation and maintenance instructions.

Hazards that must be avoided to prevent bodily injury or machine damage are identified by WARNINGS on

the compressor and in this Instruction Manual.

Never use this compressor in a manner that has not been specifically recommended by manufacturer, unle

you first confirm that the planned use will be safe for you and others.

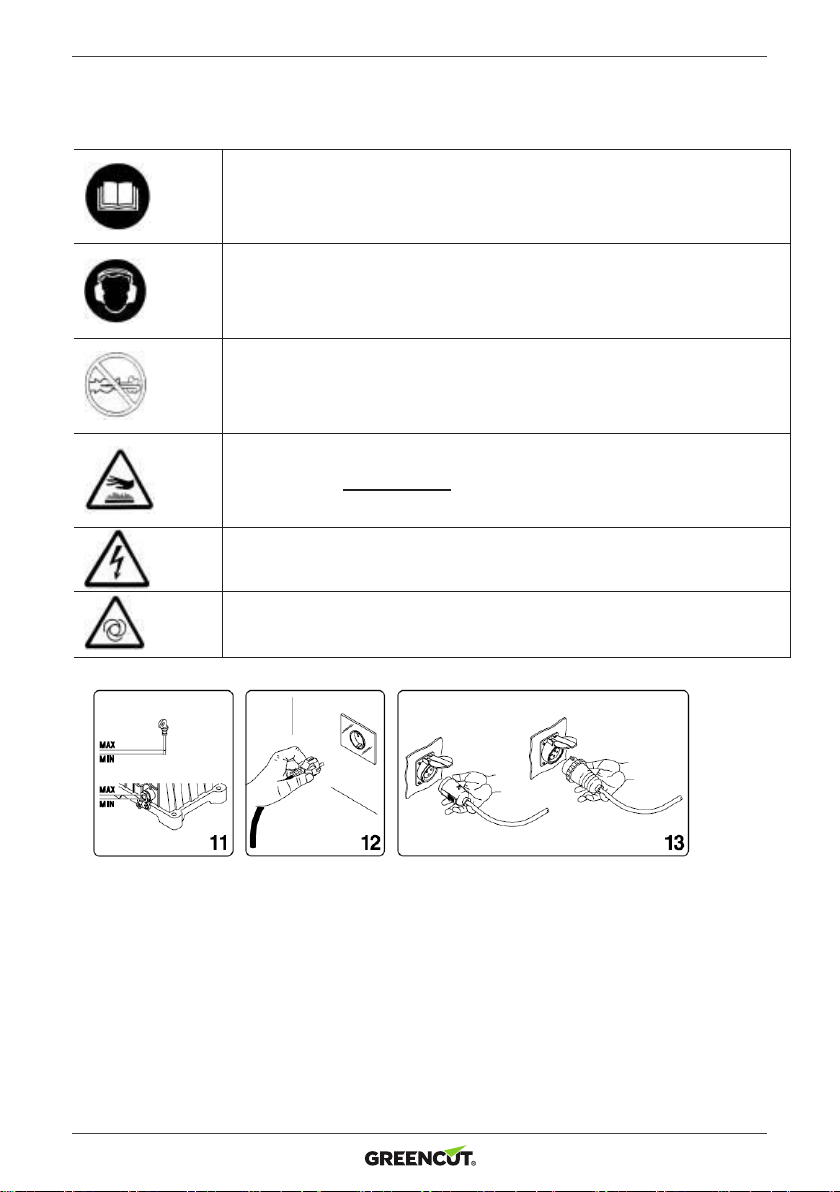

MEANINGS OF SIGNAL WORDS

WARNING: indicates a potential hazardous situations which , if ignored, could result in serious personal

injury.

CAUTION: indicates a hazardous situation which, if ignored, could result moderate personal injury or could

cause machine damage.

NOTE: emphasizes essential information

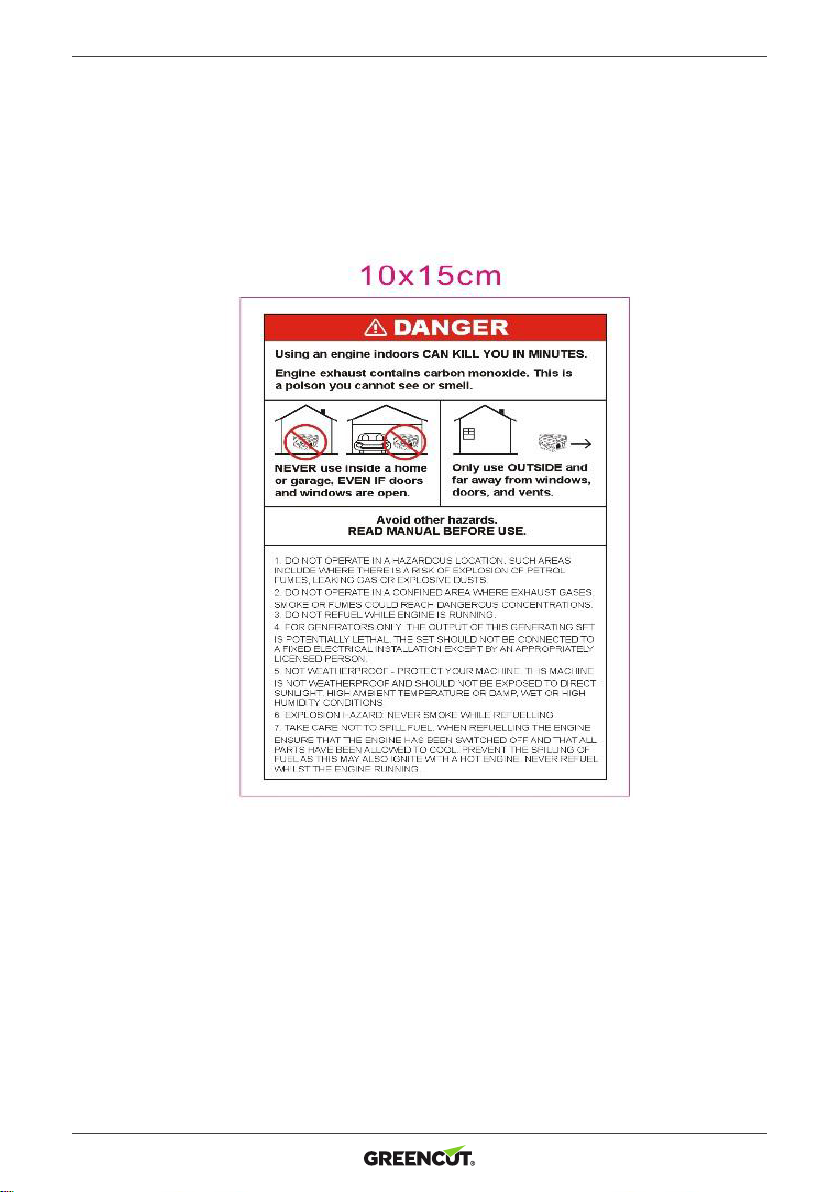

SAFETY

IMPORTANT SAFETY INSTRUCTIONS FOR USE OF THE COMPRESSOR

WARNING:

DEATH OR SERIOUS BODILY INJURY COULD RESULT FROM IMPROPER OR UNSAFE USE OF

MPRESSOR. TO AVOID THESE RISKS, FOLLOW THESE BASIC SAFETY INSTRUCTIONS.

MEANINGS OF SIGNAL WORDS

IMPORTANT INFORMATION

WARNING