© GreenGlo Limited Version 05/2010

ABOUT YOUR WATER HEATER

1. GreenG o & GreenG o Saver is a high techno ogy storage tank, backed up

by new manufacturing methods offering qua ity of goods to consumers.

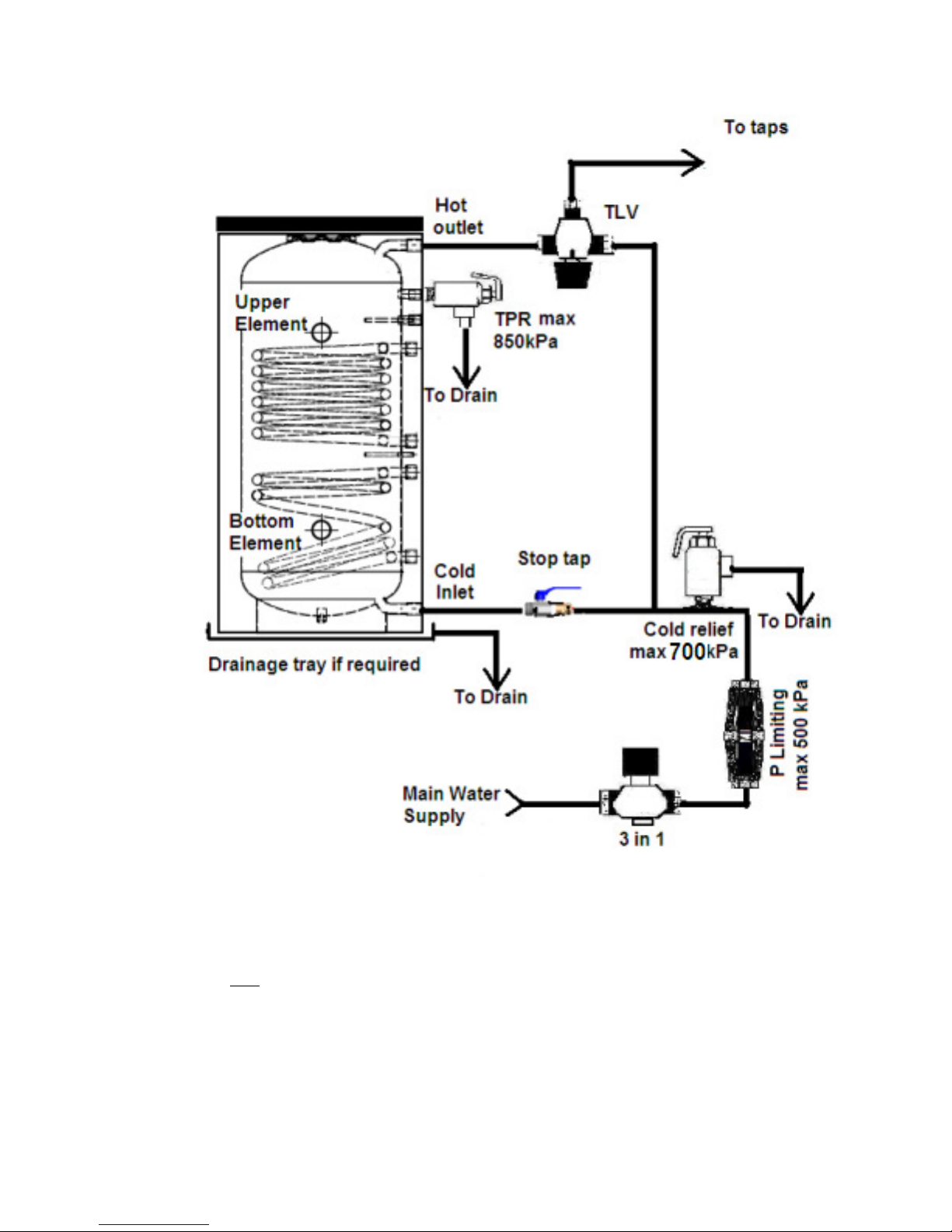

2. The main goa of producing GreenG o water heaters is heating and storing

potab e hot water in a main pressure storage tank using e ectricity.

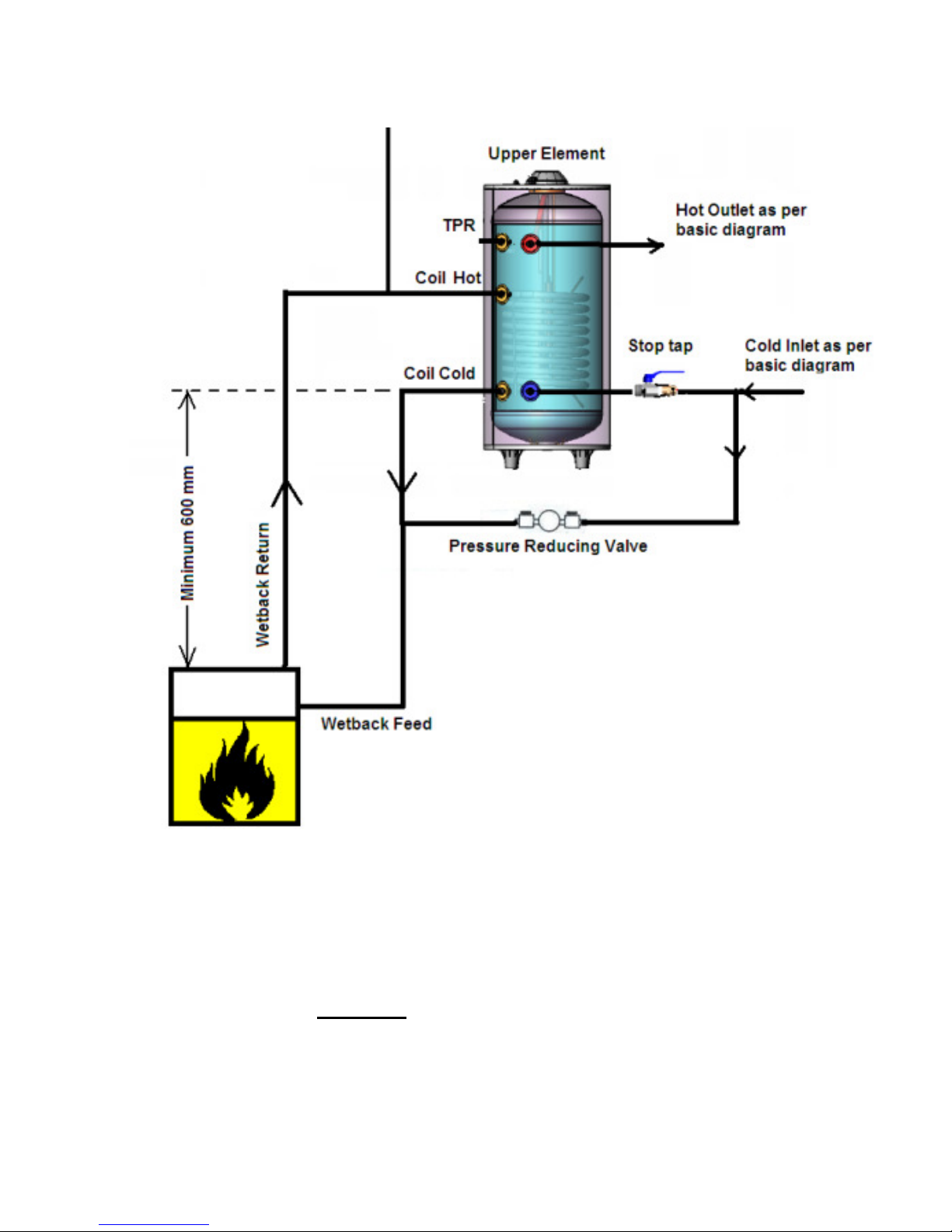

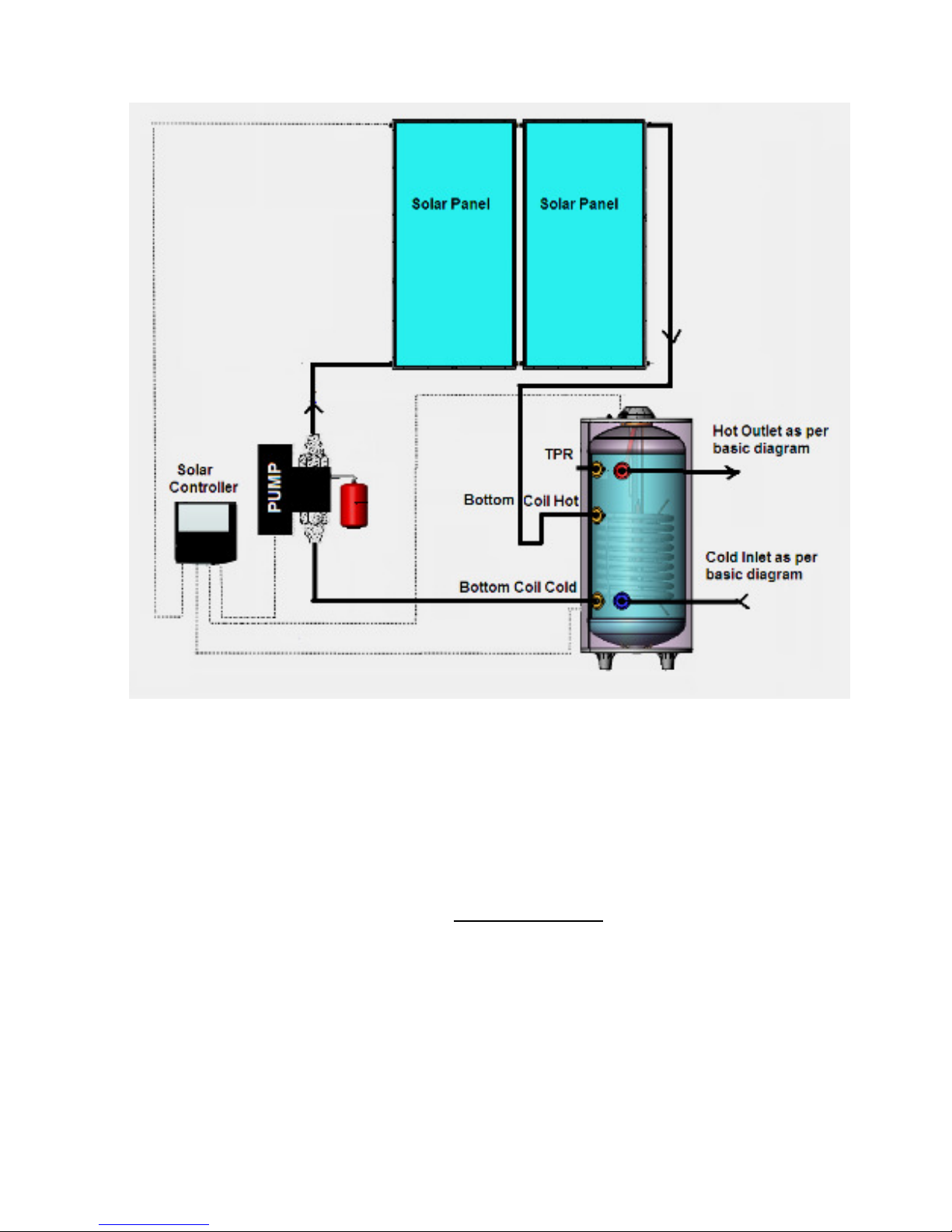

GreenG o a so offers optiona heating equipment such as so ar, gas and

wetback. Potab e hot water is stored in the main water storage tank

separate y from the heating f uids in the coi s.

3. The heating f uid, which is heated in the heat source, is circu ated

between the heat source and cy inder’s coi . The warmed f uid takes its

heat from the heat source and transmits to the water heater.

4. GreenG o cy inders inner surface is ename ed. The process used is a

doub e ename ing process that coats the inside surface of the cy inder.

5. GreenG o cy inders are protected by a magnesium anode rod in order to

prevent cathode corrosion. The magnesium anode rod ought to be

checked and rep aced if required, every 36 months by a certified p umber,

and can be done by fo owing this manua page 16.

6. GreenG o exterior surface is covered by 40 kg/m³ and 50 mm

po yurethane insu ation (except 800D and 1000D) in order to diminish the

oss of the heat. The GreenG o 800D and 1000D insu ation is removab e.

This convenience a ows easy de ivery and access through narrow

doorways. Do not remove covers un ess essentia and on y after

receiving specific instructions from GreenG o service desk

7. GreenG o is an indoor tank and sha be insta in a we vented space to

prevent condensation

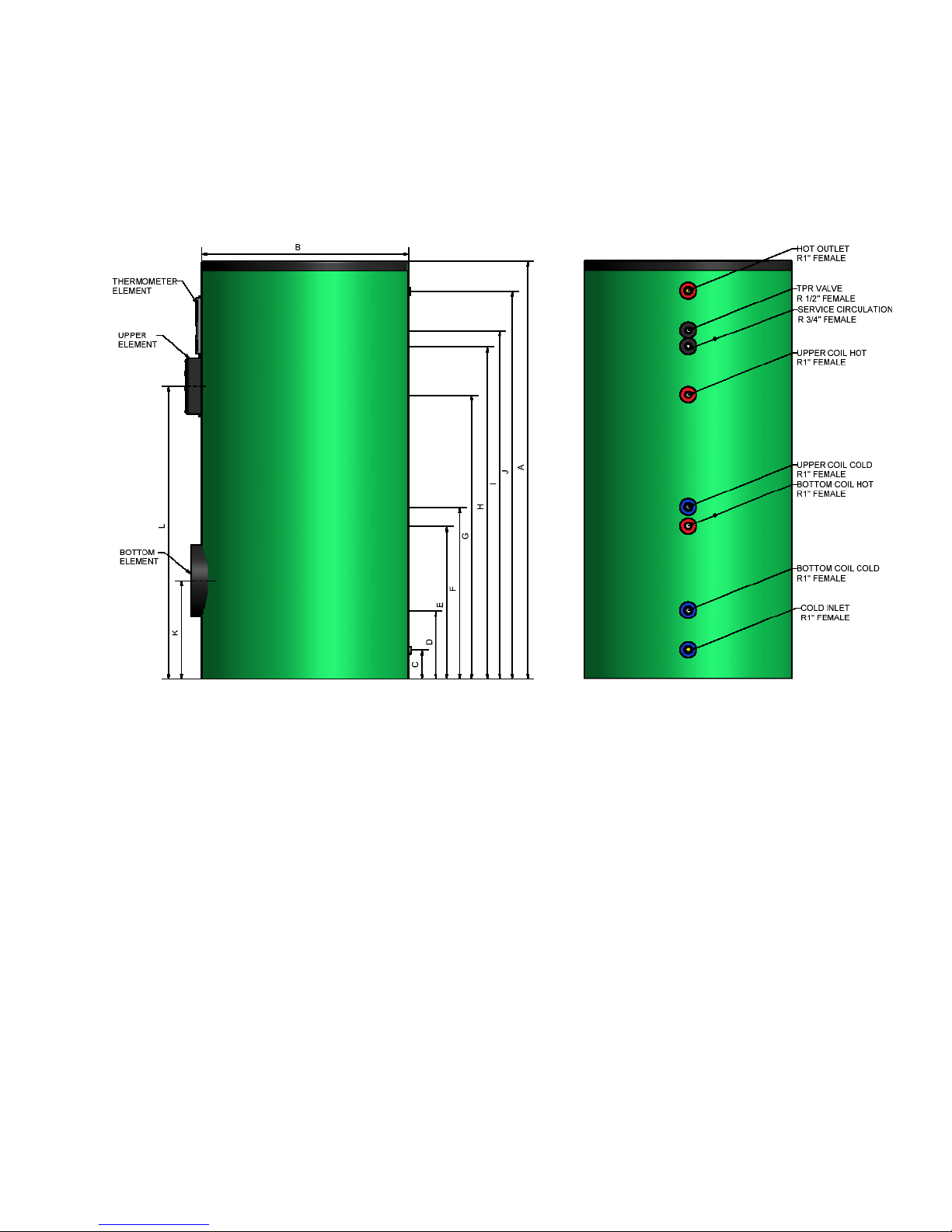

8. There is a choice of doub e or sing e or doub e coi GreenG o depending on

the app ication needed. I.E. if the cy inder wi be heated with a wetback

or a so ar system, GreenG o sing e coi water heater wou d be appropriate.

On the other hand, if the cy inder wi be heated with both wetback and a

so ar system, GreenG o doub e coi wou d be appropriate.

9. GreenG o water heaters have been produced to suit a wide range of

app ications and insta ations and are comp ying with NZS4606

In this manua we present the most common app ications, however if you

require advice on any other app ication, p ease contact our service desk on

0800 447 336 or info@greeng o.co.nz