The ERM models contain a total energy recovery wheel. The

wheels are inspected for proper mechanical operation at

the factory. However, during shipping and handling, shifting

can occur that may affect wheel operation. The wheel is

accessible through the cassette access panel.

Turn the energy recovery wheel by hand to verify

free operation. The wheel should rotate smoothly at

approximately 50-60 rpm and should not wobble. If the wheel

does not rotate when power is applied, it may be necessary

to adjust excessively tight diameter air seals.

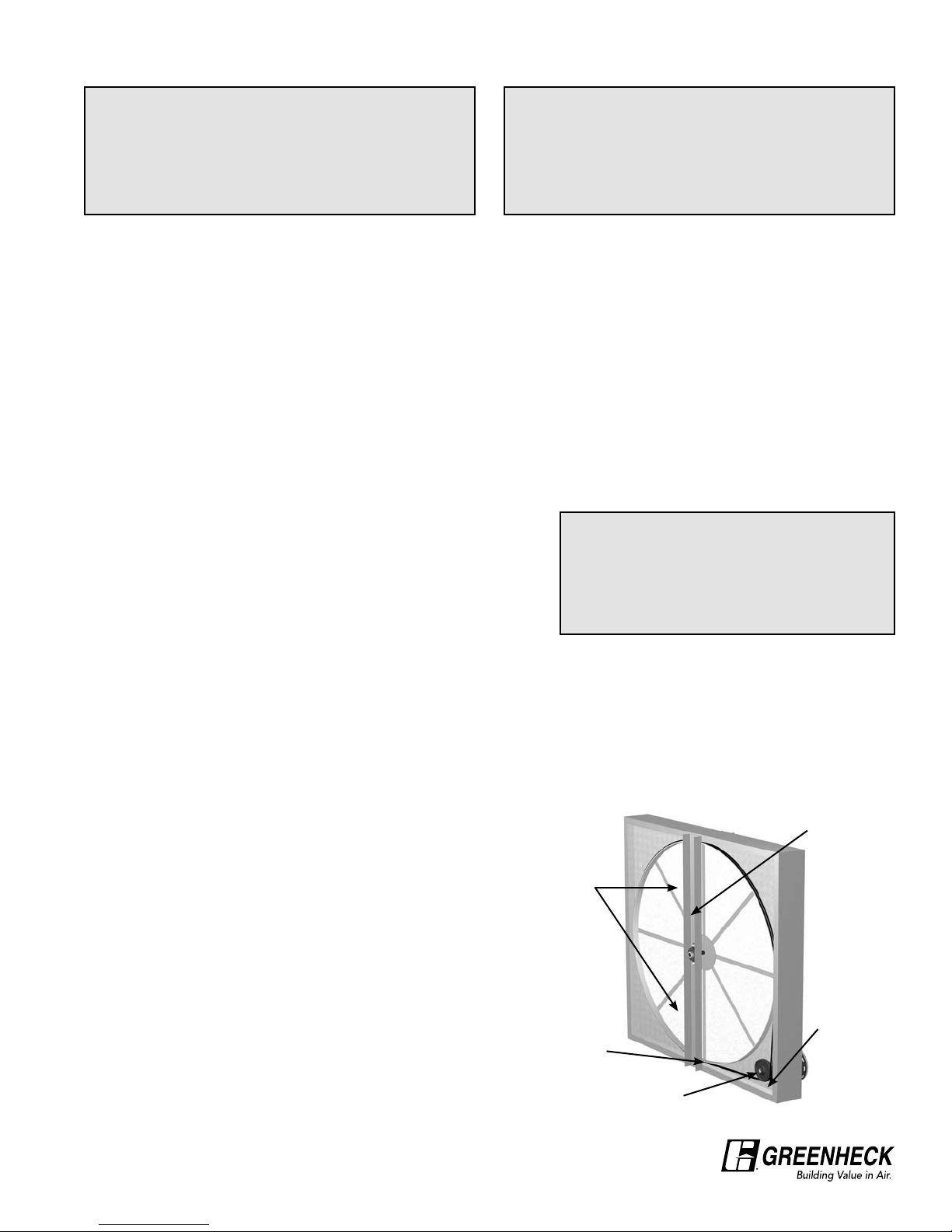

DRIVE BELT

Inspect the drive belt. Make sure the belt rides smoothly through the pulley and over the rim.

AIR SEALS

Check that the air seals located around the outside

of the wheel and across the center (both sides of

wheel) are secure and in good condition. Air seal

clearance is determined by placing a sheet of

paper, to act as a feeler gauge, against the wheel

face. To access seals, remove cassette access

panel. To adjust their seals, loosen all eight seal

retaining screws. These screws are located on

the bearing support that spans the length of the

cassette through the wheel center. Tighten the

screws so the air seals tug slightly on the sheet of

paper.

Replace cassette into ERM cabinet, plug in wheel

drive, replace access door and apply power.

Confirm that the wheel rotates freely at about

50-60 rpm.

ELECTRICAL CONNECTIONS

The electrical supply must be compatible with that shown on the wheel drive motor nameplate: voltage,

phase, and amperage capacity (see page 3 for specific requirements). Units are supplied with a receptacle

for the cassette plug and service box for wiring. Connect the ERM wiring directly to blower wiring or to

blower fan relay to power the ERM whenever the fan is in operation. All wiring must be properly fused and

conform to local and national electrical codes.

Do not operate the ERM for any extended period without airflow across the energy wheel as the drive motor

is cooled by the airflow.

MOUNTING

The ERM is shipped with a mounting kit, which contains four hanging brackets, fasteners and a separate

instruction sheet with parts list. These brackets will support the ERM in either the vertical or horizontal

position for design flexibility. A 3/8 in. x 3/4 in. hex head bolt is located at each corner of the ERM for

attaching these brackets. To hang the ERM:

Note: To reduce unit weight for handling purposes, the cassette may be removed from the cabinet (reduces

ERM-36 from 193 lbs. to 75 lbs., reduces ERM-52 from 330 lbs. to 110 lbs.).

1. To remove the cassette from the cabinet, remove the access panel and unplug the

wheel drive motor at the electrical receptacle in the cabinet.

2. Replace the access panel before mounting to insure squareness.

3. Remove the appropriate four bolts from the ERM and use to secure the brackets as

shown in Figure 1. These brackets are designed for 3/8 in. threaded hanging rods.

4. To reinstall the cassette in the mounted ERM cabinet, align

the cassette sliders with the channels in the cabinet and

slide the cassette in place. Replace access panel when

finished.

STORAGE

When a unit is not going to be in service for an extended amount of time, certain procedures should be

followed:

• Cover unit with tarp to protect from dirt and moisture (Note: do not use a black tarp as this will

promote condensation)

• Store unit in location which does not have vibration

If storage of unit is in a humid, dusty or corrosive atmosphere, rotate the fan and purge the bearings once a

month. Improper storage which results in damage to the unit or components will void the warranty.

IMPORTANT

ERM must be installed such that the energy

wheel cassette slides in and out of the cabinet

parallel to the floor.

START-UP

SAFETY CAUTION!

Use caution when removing access panels or other

unit components, especially while standing on a

ladder or other potentially unsteady base. Access

panels and unit components can be heavy and

serious injury may occur.

SAFETY DANGER!

Electric shock hazard. Can cause injury or death.

Before attempting to perform any service or

maintenance, turn the electrical power to unit to OFF.

Every installation requires a comprehensive start-up to ensure proper operation of the unit. As part of that

process, the following information must be recorded. Should an issue arise which requires factory assistance,

this important information will allow unit experts to provide quicker resolve. Qualified personnel should perform

start-up to ensure safe and proper practices are followed.

Unit Model Number ____________________________ (e.g. ERM-36H-15)

Unit Serial Number ____________________________ (e.g. 04C99999 or 10111000)

Energy Wheel Date Code ____________________________ (e.g. 0450)

Start-up date ____________________________ (MM/DD/YYYY)

Start-up Personnel Name ____________________________

Start-up Company ____________________________

Phone Number ____________________________

**WARNING**

Do not operate Energy Recovery Module

without duct filters or screens installed.

The filters and screens prevent the entry of

foreign objects such as leaves, birds, etc.

DIMENSIONAL DATA & SPECIFICATIONS

Model A B C D E F G H Voltage Hertz Phase Amps Motor

HP

Weight

Cabinet Cassette

ERM-36S-15 341/442 441/25 143/4177/8143/4121/2200-230/460 50/60 1 0.6 1/20 75 80

ERM-36H-15 341/442 441/25 143/4177/8143/4121/2200-230/460 50/60 1 0.6 1/20 75 80

ERM-36H-30 341/442 441/25 143/4177/8143/4121/2200-230/460 50/60 1 0.6 1/20 75 118

ERM-52S-15 501/2581/4603/461/2173/4177/8143/4121/2200-230/460 50/60 1 1.2 1/6 110 188

ERM-52H-15 501/2581/4603/461/2173/4177/8143/4121/2200-230/460 50/60 1 1.2 1/6 110 188

ERM-52H-30 501/2581/4603/461/2173/4177/8143/4121/2200-230/460 50/60 1 1.2 1/6 110 220

All dimensions shown are in inches.

CA

F

H

G

D

B

E

ROUTINE MAINTENANCE

Once the unit has been put into operation, a routine maintenance program should be set up to preserve

reliability and performance. Items to be included in this program are:

DATE DATE DATE DATE

______ ______ ______ ______

Energy Recovery Wheel

Check for cleanliness - clean if required oooo

Check belt for wear oooo

Check pulley, bearings, and motor oooo

INSTALLATION CLEARANCES

Provide proper clearance for cassette inspection, service or removal. Do not install ducting, piping or

wiring where it will interfere with cassette removal.

Model Inspection

or Service Removal

ERM-36 22 inches 42 inches

ERM-52 30 inches 58 inches

Storage .................................2

Electrical Connection .....................2

Mounting.................................2

Start-Up

Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

AirSeals................................3

Dimensional Data & Specifications . . . . . . . . 4

Installation Clearances . . . . . . . . . . . . . . . . . . . . 4

Rountine Maintenance

Energy Recovery Wheel . . . . . . . . . . . . . . . . . . . 5

Routine Maintenance - continued

Energy Recovery Wheel Maintenance . . . . . . . . 5

Energy Recovery Wheel Access. . . . . . . . . . . . . 5

Removal of Segments . . . . . . . . . . . . . . . . . . . . . 5

Cleaning the Energy Recovery Wheel ........5

Energy Recovery Wheel Belt . . . . . . . . . . . . . . . 5

Energy Recovery Wheel Bearings ...........5

Parts List . . . . . . . . . . . . . . . . . . . . Backcover

Troubleshooting . . . . . . . . . . . . . . . Backcover

Warranty..................... Backcover

TABLE OF CONTENTS

Drive

Belt

Drive

Pulley

Label

showing

cassette

serial #

and

date code

Adjustable

Air Seals

Bearing

Support

23 4

FIGURE 1