Barrier Mower RI 60-80 5

CONTENTS

INTRODUCTION ...........................................................................................................6

USEFUL INFORMATION ..............................................................................................7

GENERAL INFORMATION...........................................................................................8

CE DECLARATION OF CONFORMITY........................................................................9

VEHICLE / TRACTOR PREPARATION......................................................................10

Vehicle Ballast..........................................................................................................10

Front weights............................................................................................................10

Rear weights ............................................................................................................10

Factors that affect stability........................................................................................11

Suggestions to increase stability..............................................................................11

SAFETY STICKERS....................................................................................................12

SAFETY.......................................................................................................................13

Potential Dangers associated with the use of this machine......................................13

Additional Safety Advice...........................................................................................13

BEFORE USING THIS MACHINE...............................................................................15

Always:.....................................................................................................................15

Never:.......................................................................................................................16

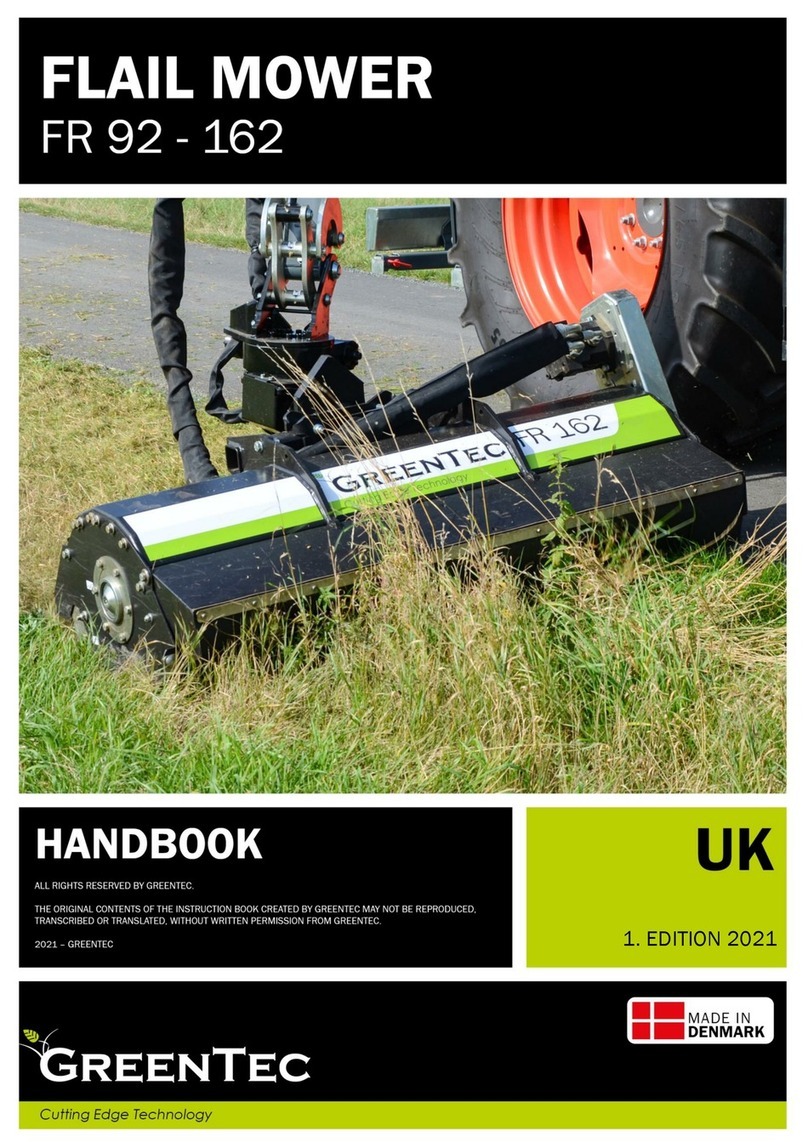

GENERAL DESCRIPTION..........................................................................................17

MOVING THE INTER-ROW MOWER .........................................................................18

INSTALLING AND CONNECTING THE INTER-ROW MOWER.................................19

Mecanical connection of Inter-row mower 60-80 for shredders................................20

Hydraulic connection to the tractor...........................................................................20

SAFETY.......................................................................................................................22

SET-UP PROCEDURE................................................................................................23

GETTING STARTED...................................................................................................24

Adjustment of the working height .............................................................................24

Start for work beginning ...........................................................................................24

Start..........................................................................................................................25

PROBLEM SOLVING..................................................................................................26

MAINTENANCE ..........................................................................................................27

Lubrication................................................................................................................27

Hydraulic hoses........................................................................................................27

Oil supply .................................................................................................................28

Pins and bushes.......................................................................................................29

Storage.....................................................................................................................29

GREENTEC WARRANTY...........................................................................................30