Side 5 af 17

Operation / Introduction

The Quadsaw is used for cutting branches and trees up to a max. diameter of (LRS 2001 120 mm).

(LRS 2401 160 mm). Branches thicker than (LRS 2001 80 mm) (LRS 2401 120 mm) must be cut one

of the time.

Vertical cutting is allowed up to a 45 degree angle. Horizontal cutting is possible on hedges with a

width up to 1.2 m and a branch diameter up to 40 mm. thicker branches might stop the blades and get

stuck in the machine.

Maintenance

After 2 hours work all Taper-lock must be retightened to 31 Nm.

After 10 hours work all bolts, screws and Taper-lock bushes must be retightened. If the bushes

loosen at a later time they may be secured with Locktite.

All bolts must be retightened on a regular basis.

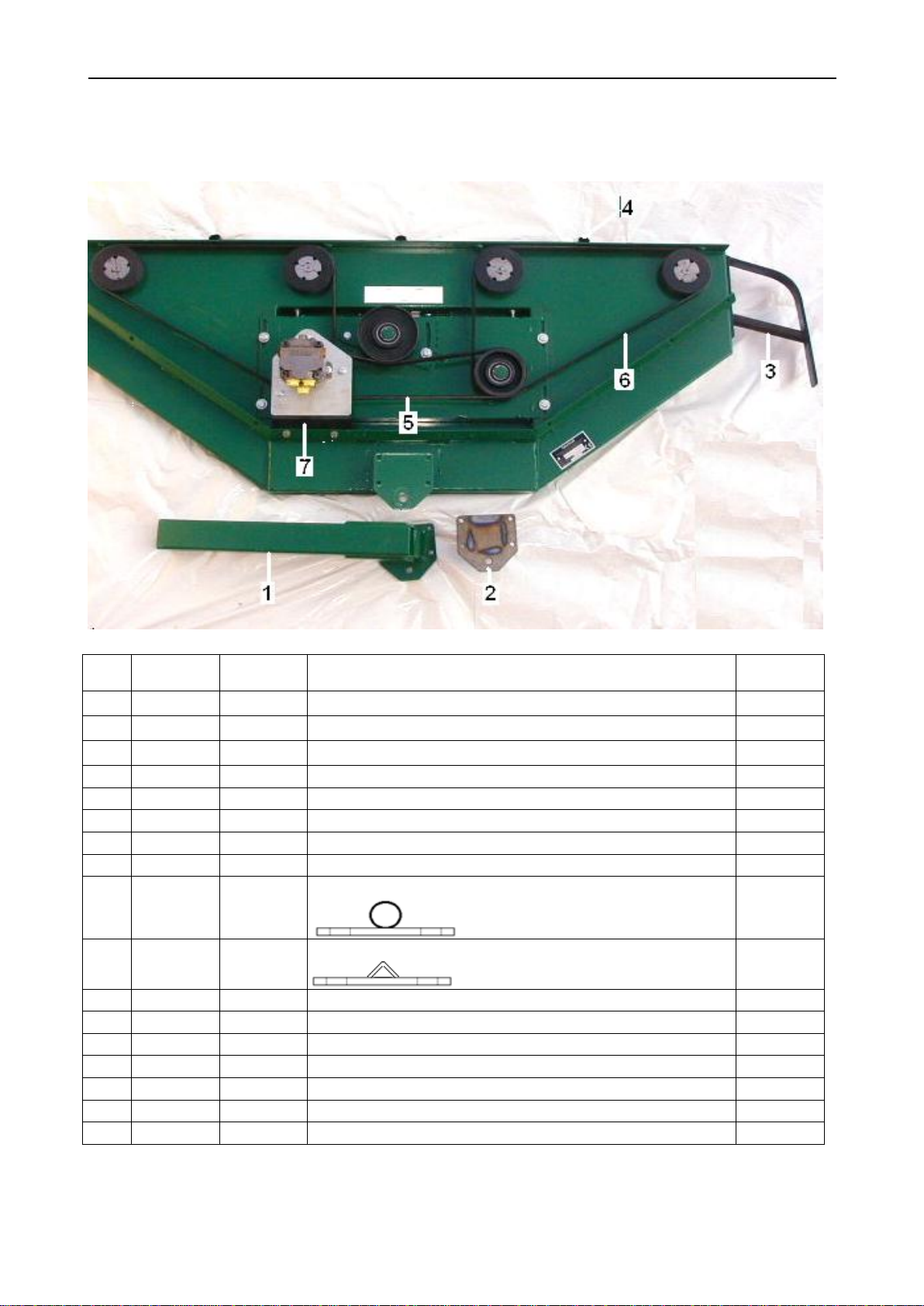

Year 2001-2011: The plastic strips are adjusted down to 1 mm clearance from the blades. The

plastic strips must be replaced if this exceeds 5 mm. The branch deflectors must be adjusted as

close as possible to the blades without touching.

Year 2011 and forward: The plastic strip on LRS 2401should be in line to the body.

Dismount the belt guard to clean the housing.

Inspect and if necessary adjust the belts. (See belt diagram here or under belt guard).

Greentec recommend changing all axles after 1500 hours of work, because of the possibility of

metal fatigue.

After inspection or service ALL protection plates and guards must be replaced.

Driving recommendations

It is recommended to travel at a slow forward speed when starting work in order to obtain and keep

the recommended rpm of the blades. Adjust the angle of the saw to approx 90 degrees in relation to

the branches. If a thick branch is approaching the branch reflectors, the working height must be ad-

justed for the branch to hit the saw blades straight on.

If small branches or other unwanted material get stuck in the blades, the machine must be stopped

and cleaned.

Always ensure that the blades are running vertical related to the direction of the travel. This will pre-

vent the blades from bending too much.

It might be an advantage to mount a skid at the bottom of the Quadsaw to prevent the saw blades

from hitting the ground. (Optional equipment)