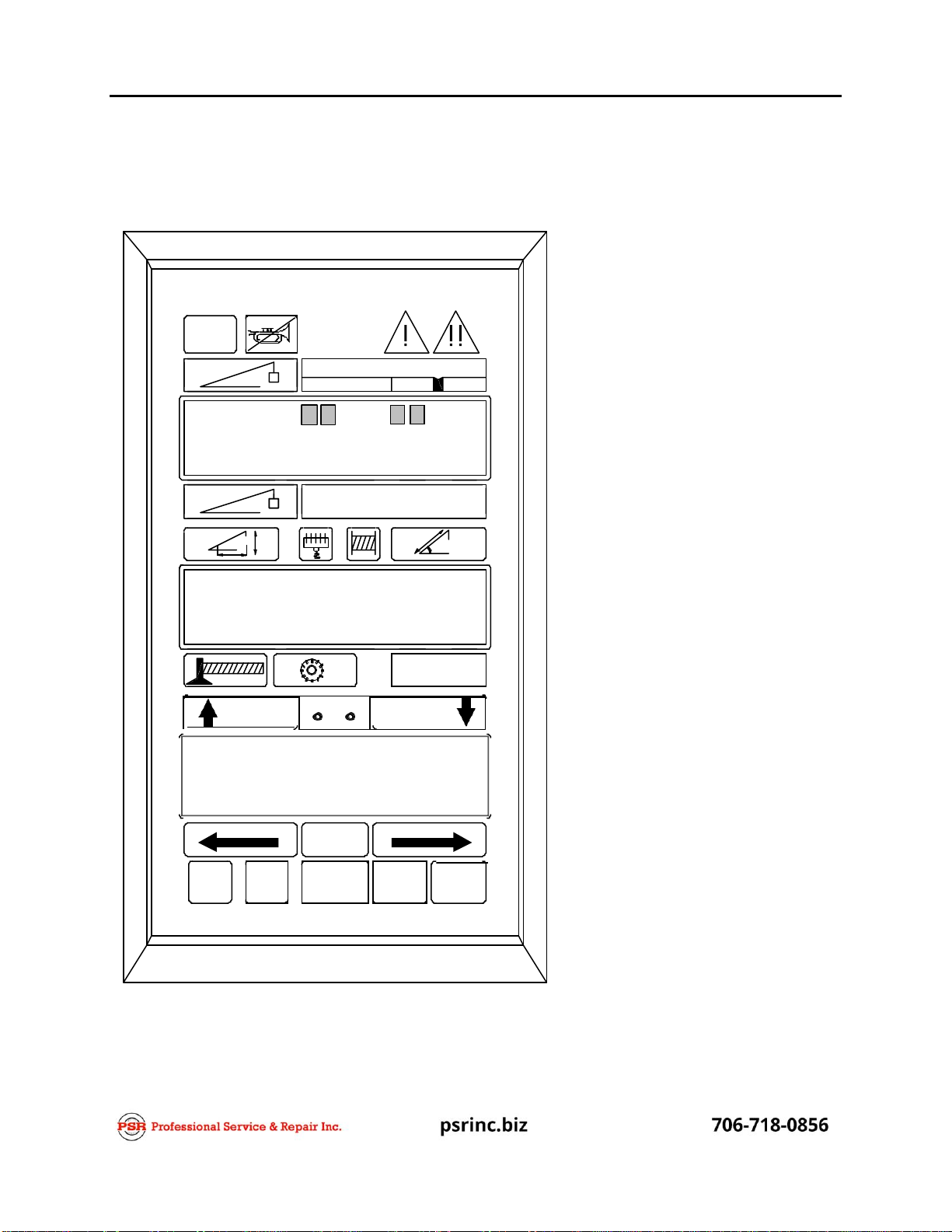

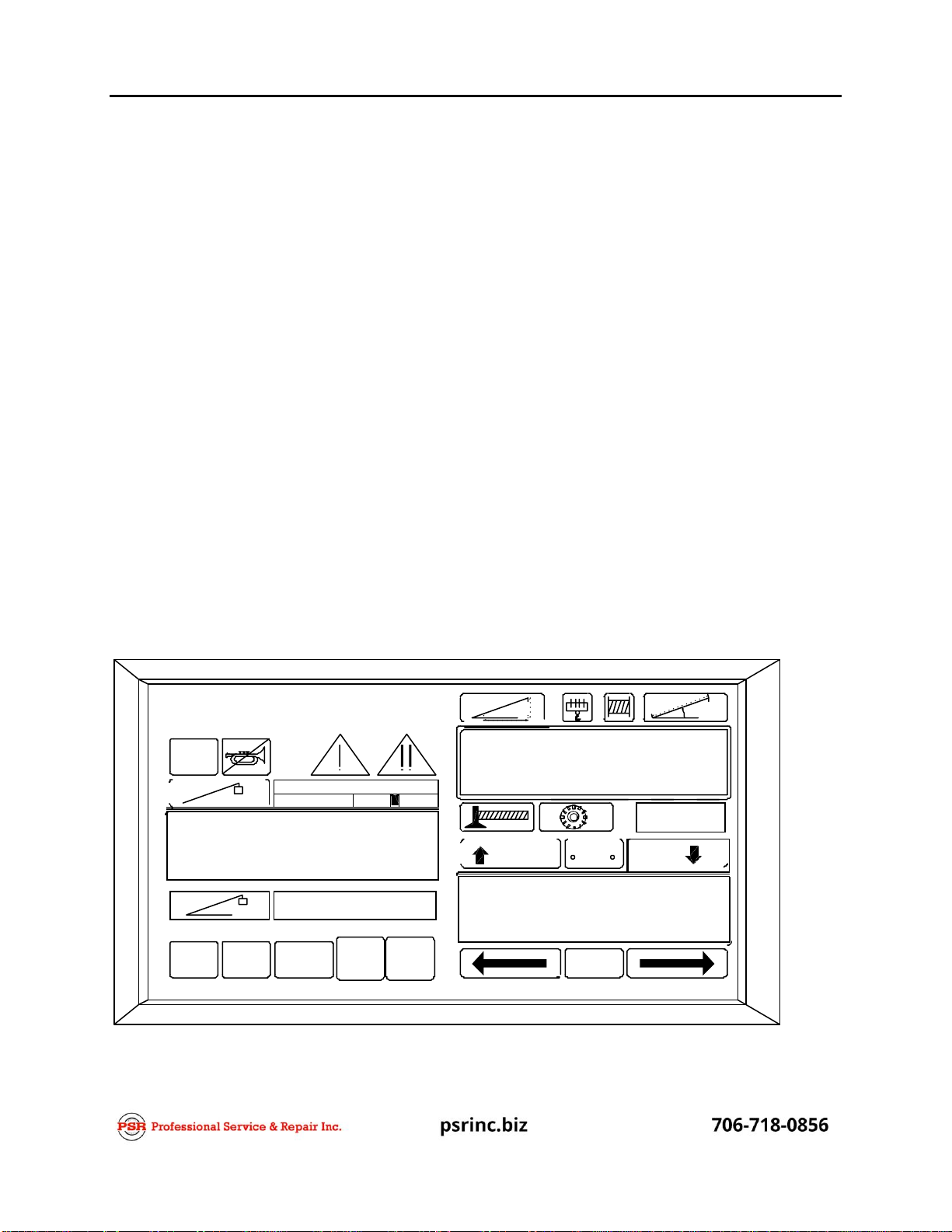

MicroGuard 404COMMISSIONING PROCEDURE FOR HYDRAULICCRANES

COMMAND 17 PERSONALITY

The Personality command is used to manipulate the crane calibration data.

The system has storage space for two sets of data in the EEPROM IC7. The active personality is the data

actually used by the main program. The second set of data is a "back-up" personality which is used to keep

a protected copy of the calibration data.

For convenience the sets of personality data are called:-

"A" the Active personality in IC7

"B" the Backup personality in IC7

Thecommandprovidesthefollowingfunctions;

display the status of the personality sets.

move data between the two sets

delete data from the active personality.

copy data to a back-up chip

retrieve data from a back-up chip.

When the command is first selected and after copying data, both "A" and "B" sets are checked for correct

check-sum. This is indicated by "good" or "bad" beside the respective reference in the lower display. Set

"A" is also checked against set "B". If the data is identical this is indicated by "same" or if not the same by

"diff". Moving of data is bymeans of sub-commands selected and a special [CAL] sequence. This requires

the entry of a code which is the same as the one used to enter the calibration routines and provides

adequate opportunity to abort the procedure. This isnecessary because some of the sub-commands cause

previously entered data to be irretrievably lost.

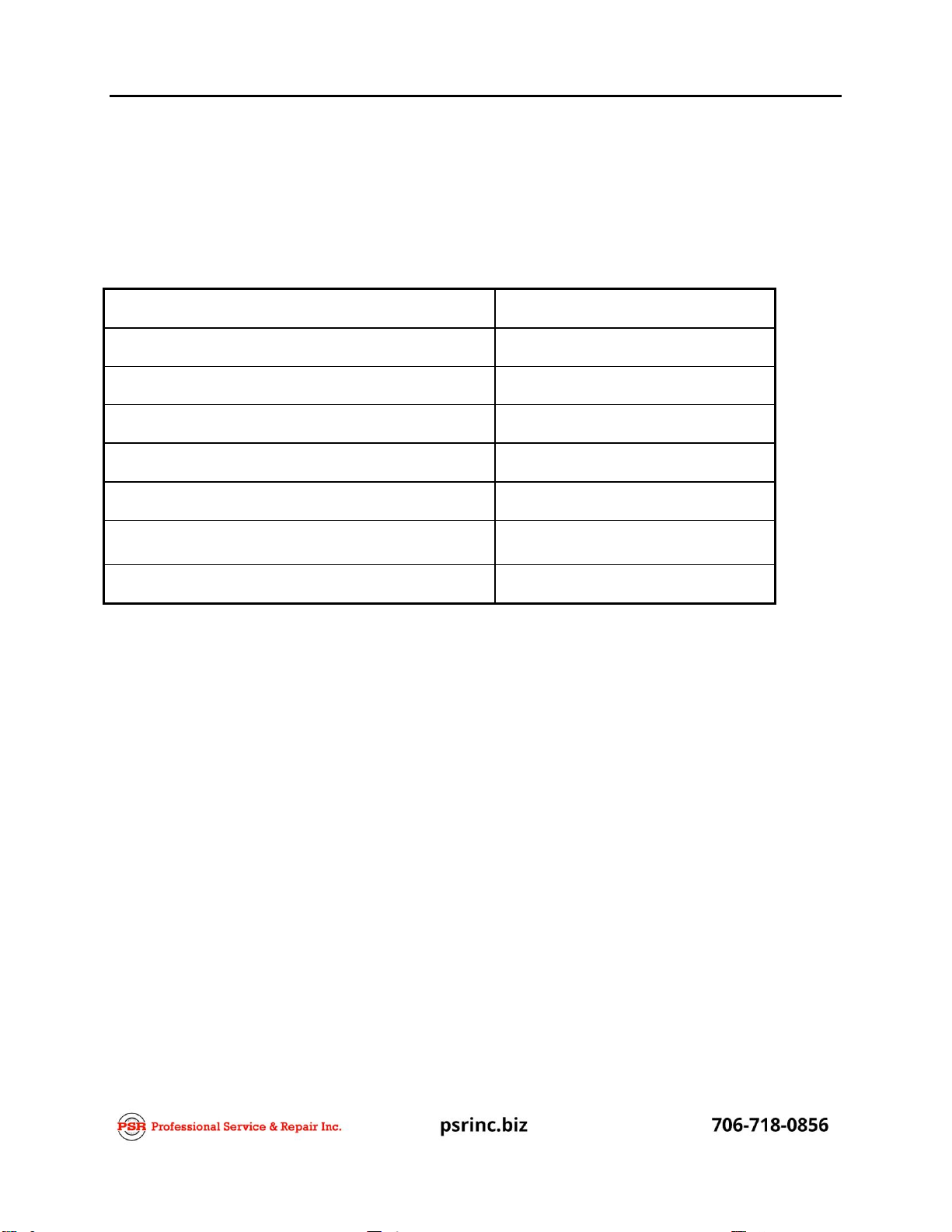

SUB-COMMAND 0 SAVE Saves "A" into "B". (B data is lost)

SUB-COMMAND 1 XCHG Exchanges "A" with "B" (data is not lost)

SUB-COMMAND 2 INIT Initializes "A" prior to new calibration.

SUB-COMMAND 3 BACK Copies the active calibration to a back-up chip.

SUB-COMMAND 4 RETR Retrieves the calibration from a back-up chip.

WARNING

POWER TO THE SYSTEM SHOULD BESWITCHED OFF BEFORE INSERTING OR REMOVINGANY

INTEGRATED CIRCUITS. FAILURE TO OBSERVE THIS PRECAUTION MAY CAUSE PERMANENT

DAMAGE TO THE SYSTEM OR ITS COMPONENTS AND RESULT IN THE LOSS OF CALIBRATION

DATA.