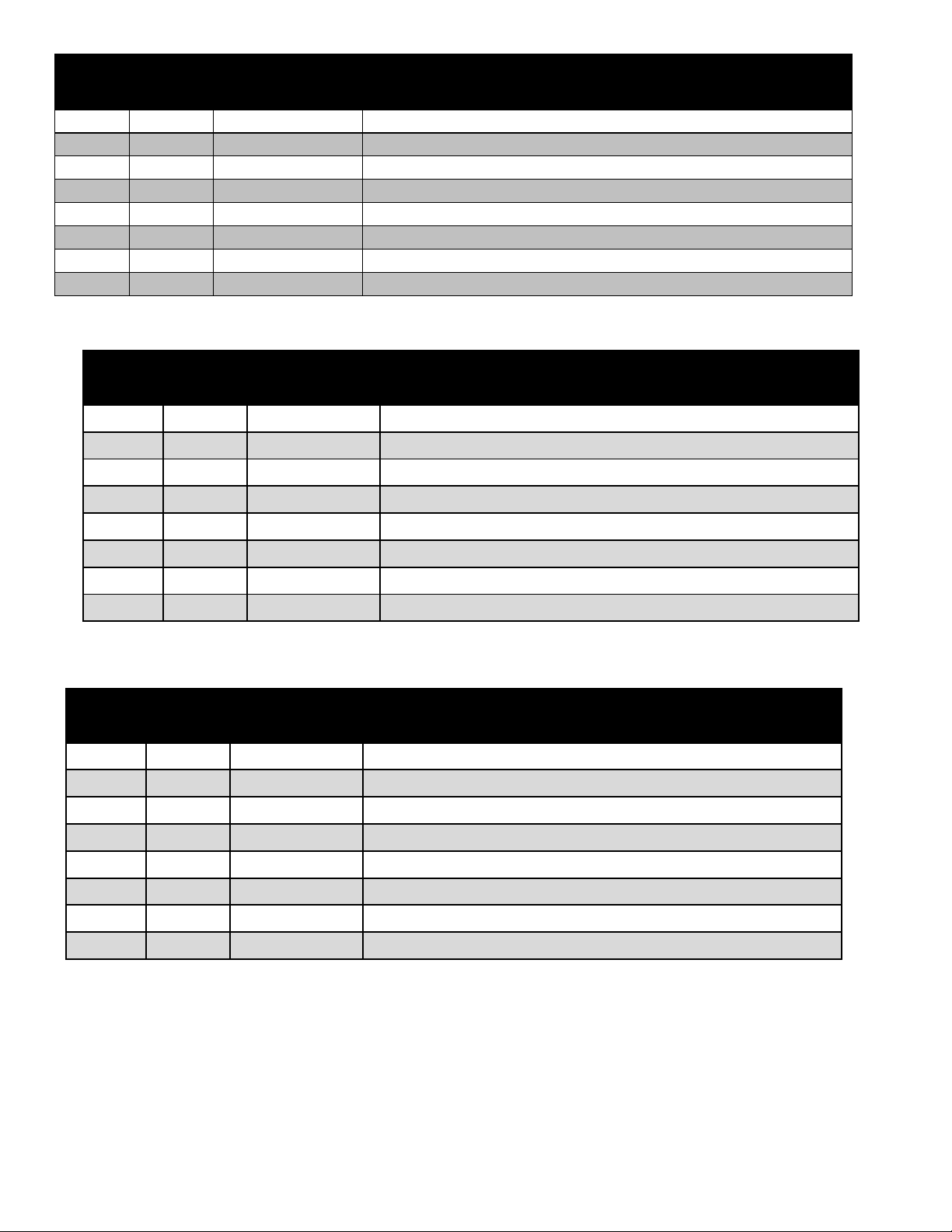

6

00055629 PLOW, MP44R11-ISDT, 10GA, 8RIB, DUAL TRIP, TT EDGE

1 1 00104997 MLDBD ASSY,PLOW,MP44R11-ISDT,10GA

2 1 00055931 CE KIT,11',.75x6,CARBIDE,TPCS,COV

3 1 00050926 REVERSING KIT,PLOW,3x10 CYL

4 1 00107506 PUSHFRAME KIT,RVS,39&44DT,9'-12'

5 1 00080105 TRIP KIT,PLOW,DUAL TRIP,HD

6 1 05050095 TAG,SERIAL NUMBER,STANDARD

7 1 00055962 DECAL KIT,PLOW

8 1 05090227 MANUAL,PLOW,DT,DUAL TRIP

See page 7

See page 8

See page 9

See page 11

See page 13

See page 14

ITEM QTY PART NUMBER DESCRIPTION

1 1 00157336 MLDBD ASSY,PLOW,MP44R12-ISTT-

2 1 00049754 CE KIT,12',.625 x 8.000,TPCSK

3 1 00110870 REVERSING KIT,PLOW,3x15 CYL,

4 1 00128418 PUSHFRAME KIT,RVS,TE,10'-12',4

5 1 00080105 TRIP KIT,PLOW,DUAL TRIP,HD

6 1 05050095 TAG,SERIAL NUMBER,STANDARD

7100055962DECALKIT,PLOW/WING

8 1 05090227 MANUAL,PLOW,DUAL TRIP

0000115577774433PPLLOOWW,,MMPP4444RR1122--IISSDDTT--MMBB11,,1100GGAA,,1122XX2200RRHH,,55""TTUUBBEE

ITEM QTY PART NUMBER DESCRIPTION

1 1 00157334 MLDBD ASSY,PLOW,MP44R11-ISTT-

2 1 00049753 CE KIT,11',.625 x 8.000,TPCSK

3 1 00110870 REVERSING KIT,PLOW,3x15 CYL,

4 1 00128418 PUSHFRAME KIT,RVS,TE,10'-12',4

5 1 00080105 TRIP KIT,PLOW,DUAL TRIP,HD

6 1 05050095 TAG,SERIAL NUMBER,STANDARD

7100055962DECALKIT,PLOW/WING

8 1 05090227 MANUAL,PLOW,DUAL TRIP

0000115577774422PPLLOOWW,,MMPP4444RR1111--IISSDDTT--MMBB11,,1100GGAA,,1122XX2200RRHH,,55""TTUUBBEE

See page 7

See page 8

See page 10

See page 12

See page 7

See page 8

See page 13

See page 14

See page 10

See page 12

See page 13

See page 14