Operating Manual SL1

This device is built according to state-of-the-art, recognised safety regulations. However, when in use

dangers can arise to the life and limb of those operating it or third parties, and/or adverse effects to

the device and other property.

For this reason, we would ask you to please comply with the safety instructions below:

(1) The device must only be used in technically perfect condition in accordance with its designated use and

the instructions set out in the operating manual, and only by safety-conscious persons who are fully

aware of the risks involved in operating the unit. No claims under guarantee can be entertained in the

event of operator error or lack of maintenance.

(2) Before putting into service, check the information on the type plate on the rear of the device. The device

is designed for a 115 or 230 V power supply and may only be connected to mains sockets of this type.

(3) In the event of any faults that could also have a detrimental impact on safety, have them repaired by the

manufacturer immediately, as the unit will otherwise not be covered by any guarantee or liability for

defects.

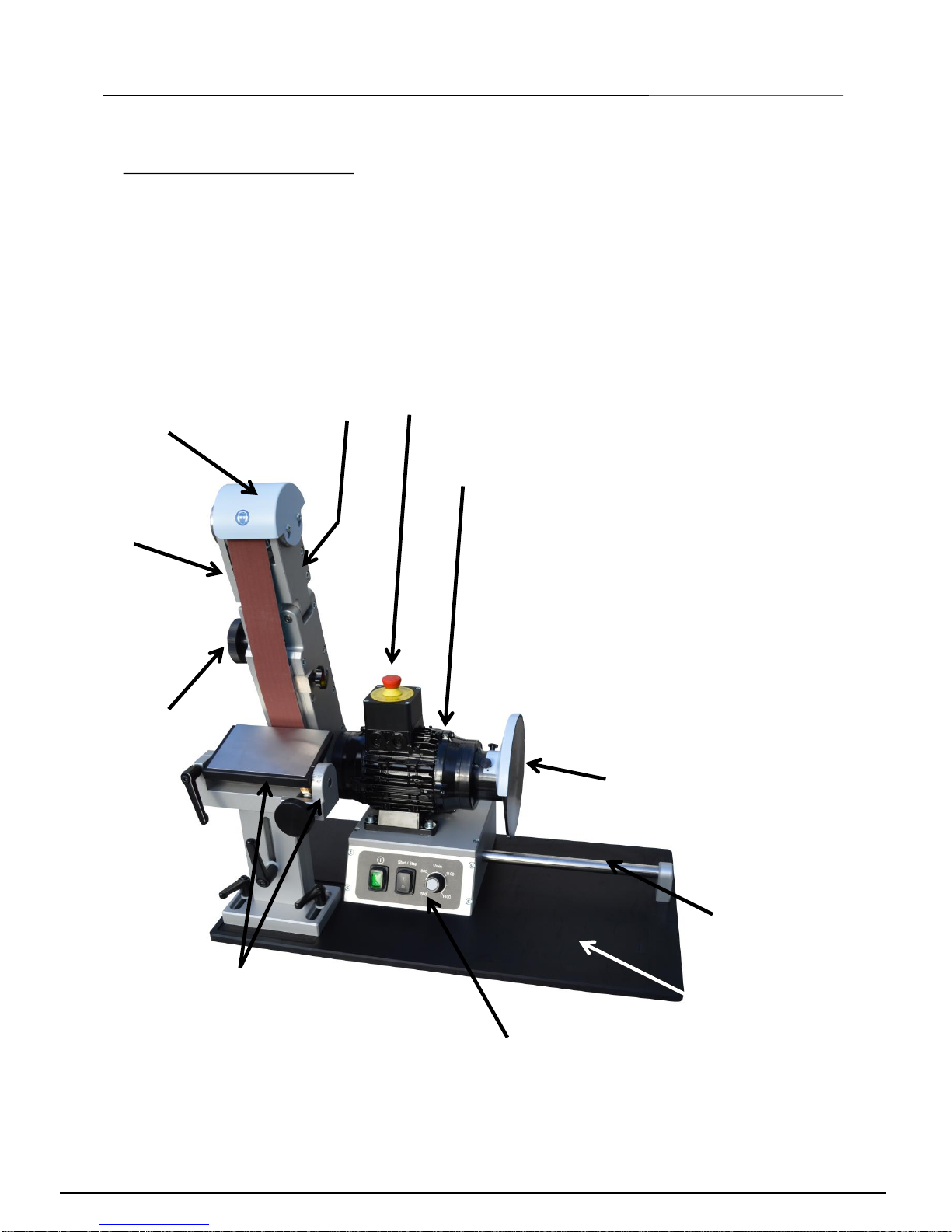

(4) The device is intended exclusively for grinding, milling, scratching and polishing with approved tools. Any

other use or use above and beyond the specifications will be regarded as improper use. The

manufacturer cannot accept any liability for damage resulting from such improper use.

The risk will be borne entirely by the user.

(5) As an additional security equipment the polishing machine is inclusive an emergency stop button.

(6) Always keep the Operating Manual carefully to hand at the location where the device is used.

(7) Supplementary to the Operating Manual, all generally valid statutory and other binding regulations

relating to accident prevention and environmental protection must be observed and communicated to

others.

(8) Personnel entrusted with the operation of the device must, before starting work, have read the Operating

Manual and in particular the Safety instructions chapter.

This is especially important in the case of personnel who only work with the device occasionally.

(9) DO NOT WEAR any jewellery, ties or loose clothing. Loose clothing can get caught up in rotating

parts and cause severe injuries. Use appropriate protection if you have long hair.

(10) Protect the mains cable from heat and sharp objects and install it in such a way that it cannot be

damaged. When not in use, before maintenance, tool changing or repairs, DISCONNECT THE

MAINS PLUG. When disconnecting the mains plug, be sure not to pull by the cable, but by the plug.

If the cable has to be extended, make sure it is in perfect condition and, before use, ensure correct

current carrying capacity.

(11) Never use the device in a humid environment or close to combustible liquids or gases.

(12) The device must NOT be used for wet grinding jobs.

(13) Do not overload the device and clean thoroughly after use.

(14) In the event of damage to the polisher, disconnect the mains plug immediately. It may not be used

again until it has been repaired. Faulty mains cables must be replaced immediately.

(15) Always wear safety goggles with shatter-proof clear lenses.

(16) Spare parts must comply with the technical requirements specified by the manufacturer. This can

only be guaranteed in the case of original spare parts from Helmut Klein company.

(17) Work on/with the device may only be carried out by qualified, appropriately trained and assigned

personnel.

Be sure to observe the legally permitted minimum age !

(18) Store the Operating Manual carefully.

Page 5

4. Safety instructions