G-FIRE Figure 522

Sprinkler Outlets

Worldwide

Contacts

www.tyco-fire.com

Page 1 of 4 AUGUST 2018 TFP1865

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

General

Description

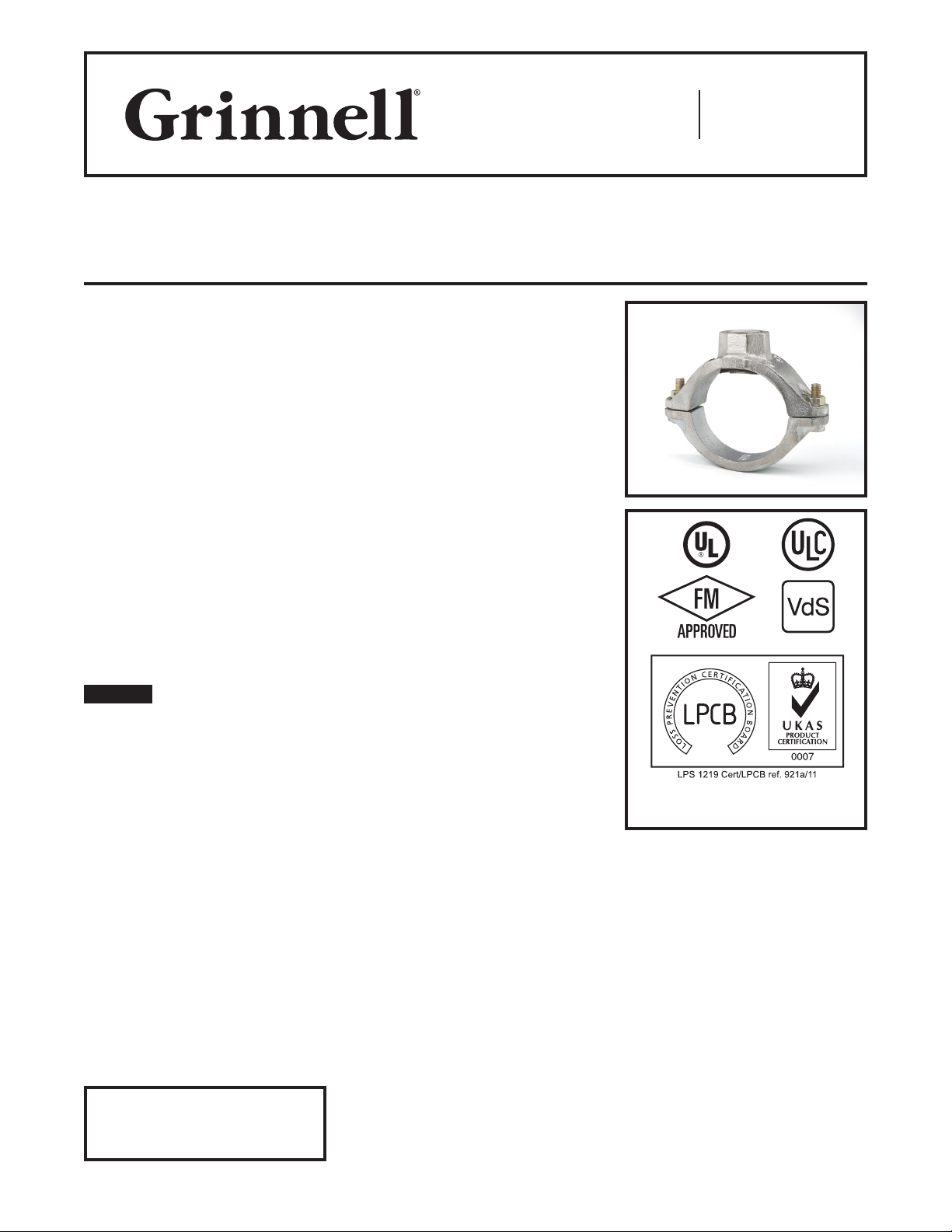

The GRINNELL G-FIRE Figure 522

Sprinkler Outlet is an economical alter-

native to welded pipe outlets on steel

pipe. The Figure 522 Sprinkler Outlet

may be used with full lengths of pipe

and eliminates threading and welding,

decreasing waste and installation time.

The Figure 522 Sprinkler Outlet may be

used in wet pipe, dry pipe, and deluge

systems.

The 1/2 in. and 3/4 in. nominal outlet

sizes are intended for use in fire pro-

tection systems leading to a direct con-

nection to a sprinkler only. The 1 inch

nominal outlet size is intended for use

in fire protection systems leading to a

direct connection to a sprinkler or a

connection to system piping. These fit-

tings should be used for hydraulically

calculated systems only.

NOTICE

Never remove any piping component

nor correct or modify any piping defi-

ciencies without first de-pressurizing

and draining the system. Failure to do

so may result in serious personal injury,

property damage, and/or impaired

device performance.

It is the designer’s responsibility

to select products suitable for the

intended service and to ensure that

pressure ratings and performance

data are not exceeded. Material and

gasket selection should be verified to

be compatible for the specific applica-

tion. Always read and understand the

installation instructions.

The GRINNELL G-FIRE Figure 522

Sprinkler Outlet described herein

must be installed and maintained in

compliance with this document, as

well as with the applicable standards

of the Approval agency, in addition to

the standards of any other authorities

having jurisdiction. Failure to do so

may result in serious personal injury

or impair the performance of these

devices.

The owner is responsible for main-

taining their mechanical system and

devices in proper operating condition.

The installing contractor or device man-

ufacturer should be contacted with any

questions.

Technical

Data

Approvals

UL and ULC Listed

FM Approved

VdS Approved

LPCB Certified

Maximum Working Pressure

300 psi (20,7 Bar)

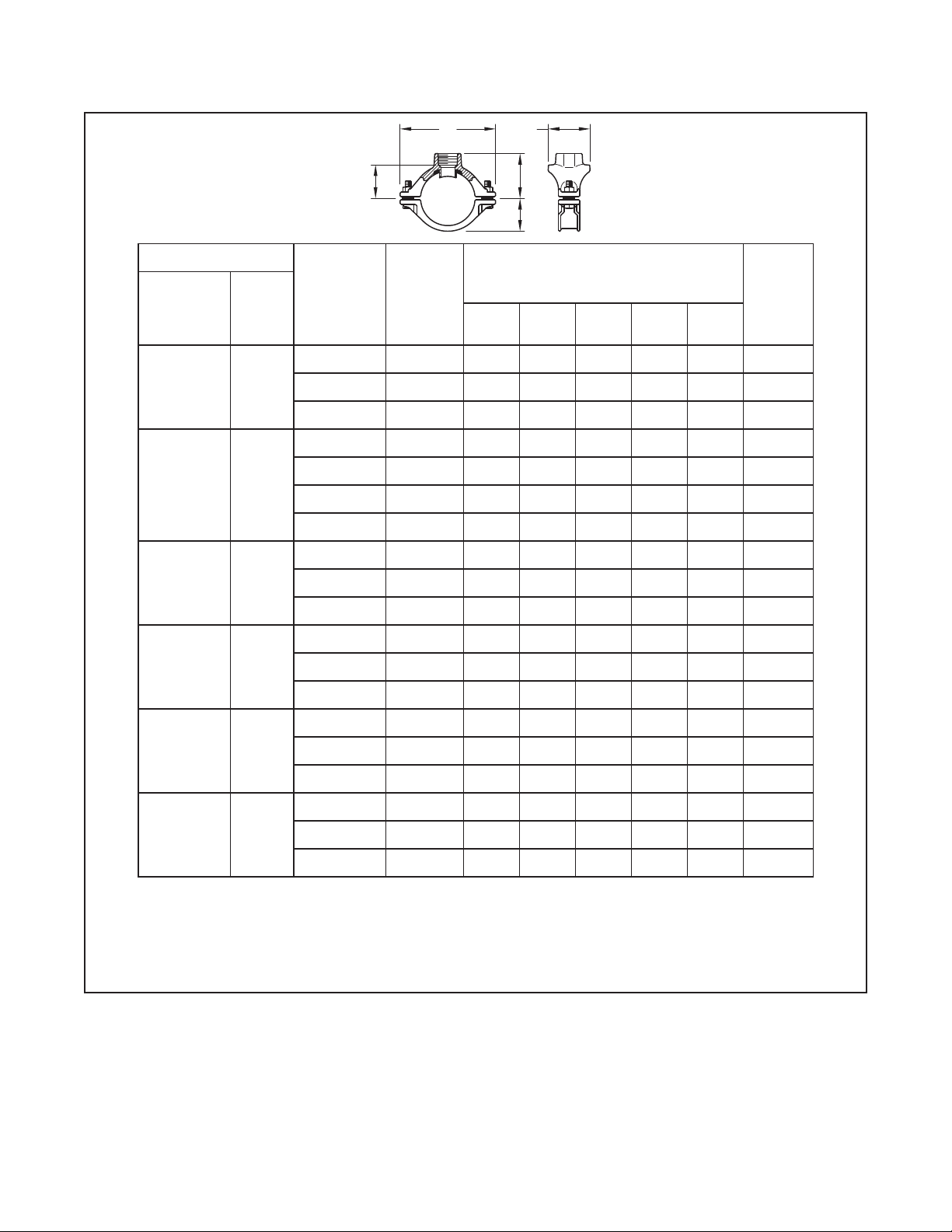

Sizes

• Run Sizes

1 in., 1-1/4 in., 1-1/2 in., 2 in.,

2-1/2 in., 76,1 mm (DN25, DN32,

DN40,DN50, DN65)

• Outlet Sizes

NPT or ISO 7-1 Pipe Threaded

3/8 in., 1/2 in., 3/4 in., 1 in.

(DN10, DN15, DN20, DN25)

Housing Materials

Ductile Iron conforming to

ASTM A 536, Grade 65-45-12

Finish

• Zinc electroplate conforming to

ASTM B 633 Type III

• Red (RAL3000) painted nish for

ISO Thread only

• Orange painted nish for

NPT Thread only

Bolts

Conforming to DIN 933,

M8 x 30 mm Class 8.8

Nuts

Flange nuts conforming to DIN 934, Class

8

Gasket

Grade “E” EPDM, Green color code

-30°F to 230°F (-34°C to 110°C)

See Data Sheet TFP1865 for additional

gasket information.

Friction Loss

Equivalent length of 1 in. Schedule 40 pipe

is 15 ft (4,6 m).

Hazen Williams coefficient = 120

For re protection pressure rating,

listing and approval information, contact

your GRINNELL representative.