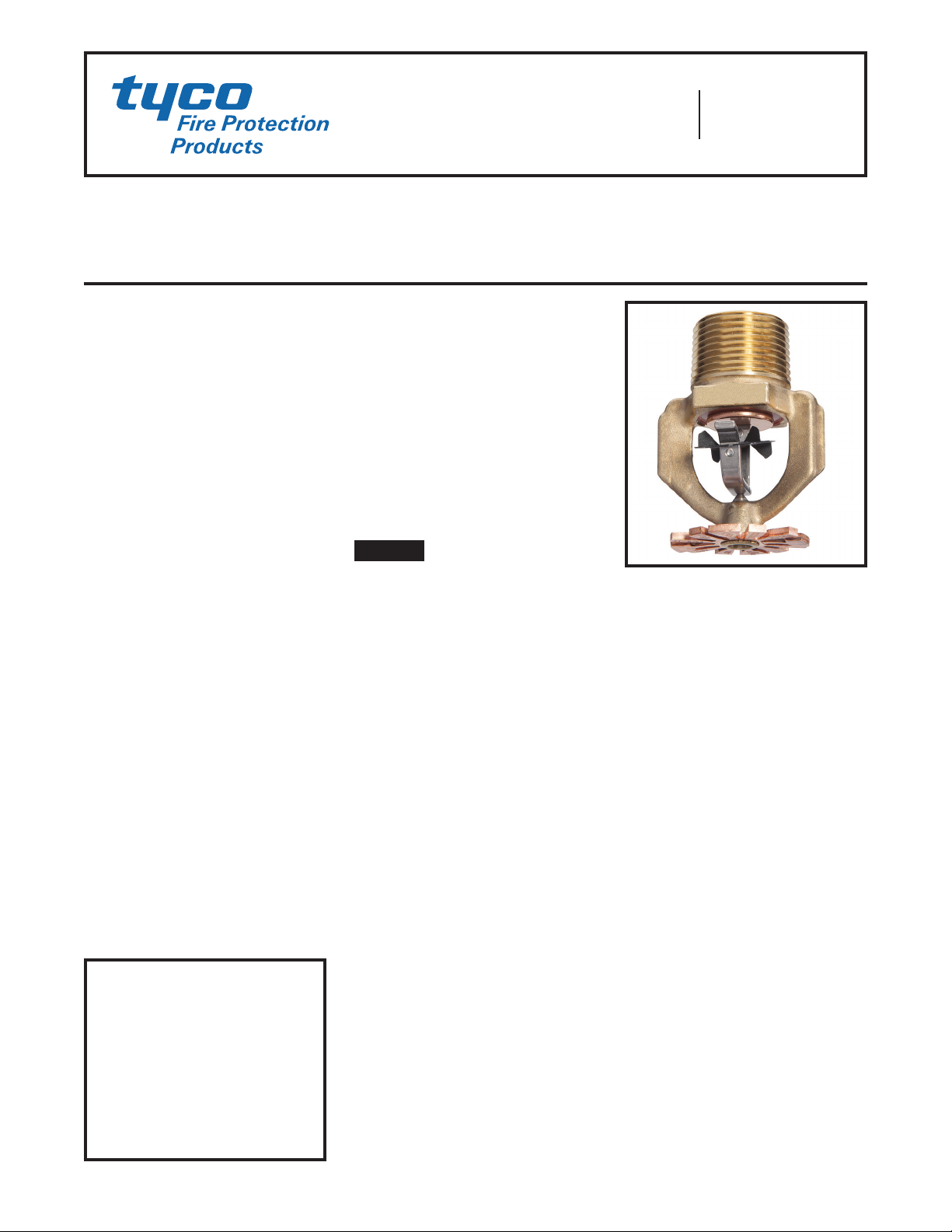

Model ESFR-17

16.8 K-factor Pendent Sprinkler

Early Suppression, Fast Response

Page 1 of 4 APRIL 2015 TFP317

IMPORTANT

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and instal-

lation of sprinkler systems and com-

ponents. Improper handling and

installation can permanently damage

a sprinkler system or its compo-

nents and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

Technical

Data

Approvals

UL Listed

C-UL Listed

FM Approved

Maximum Working Pressure

175 psi (12,1 bar)

Pipe Thread Connections

3/4 Inch NPT or ISO 7-R 3/4

Discharge Coefficient

K=16.8 gpm/psi1/2 (241,9 lpm/bar1/2)

Temperature Ratings

165°F (74°C) and 212°F (100°C)

Finish

Natural Brass

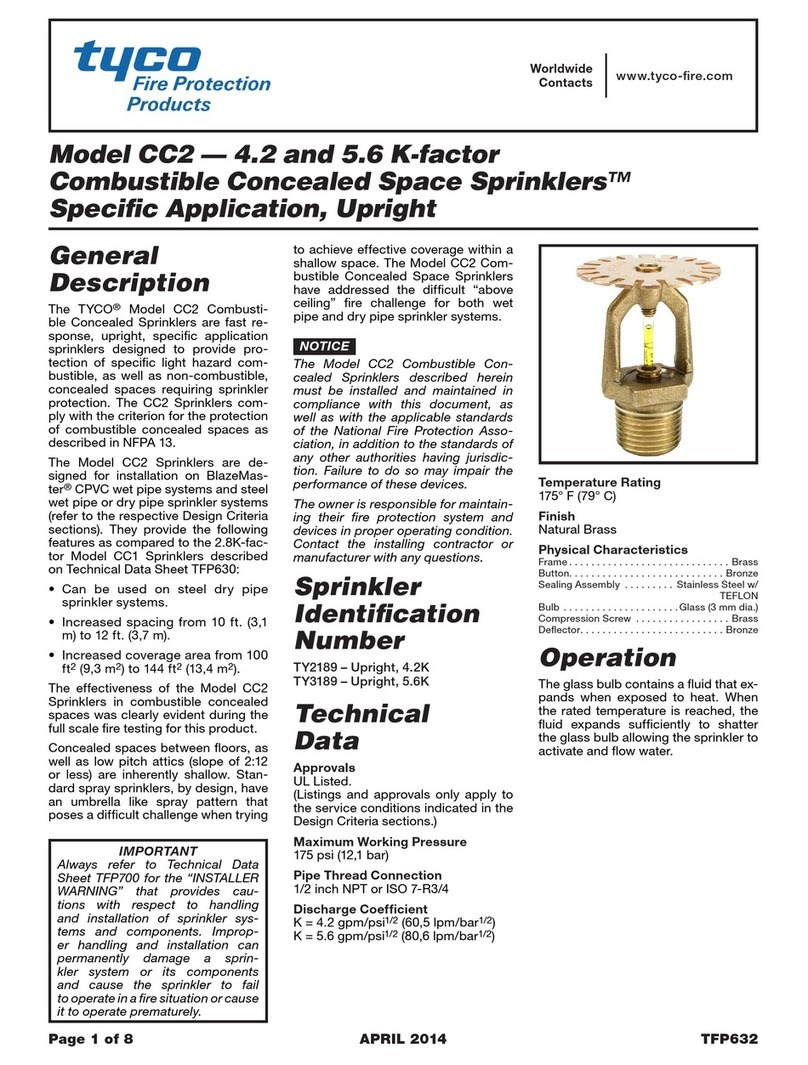

Physical Characteristics

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Brass

Deflector . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Compression Screw . . . . . . . . . . Stainless Steel

Hook . . . . . . . . . . . . . . . . . . . . . . . . . . . . MONEL

Strut. . . . . . . . . . . . . . . . . . . . . . . . . . . . . MONEL

Link Assembly. . . . . . . . . . . . . . . . Solder, Nickel

Button ...................Phosphor Bronze

Sealing Assembly ..Beryllium Nickel w/TEFLON

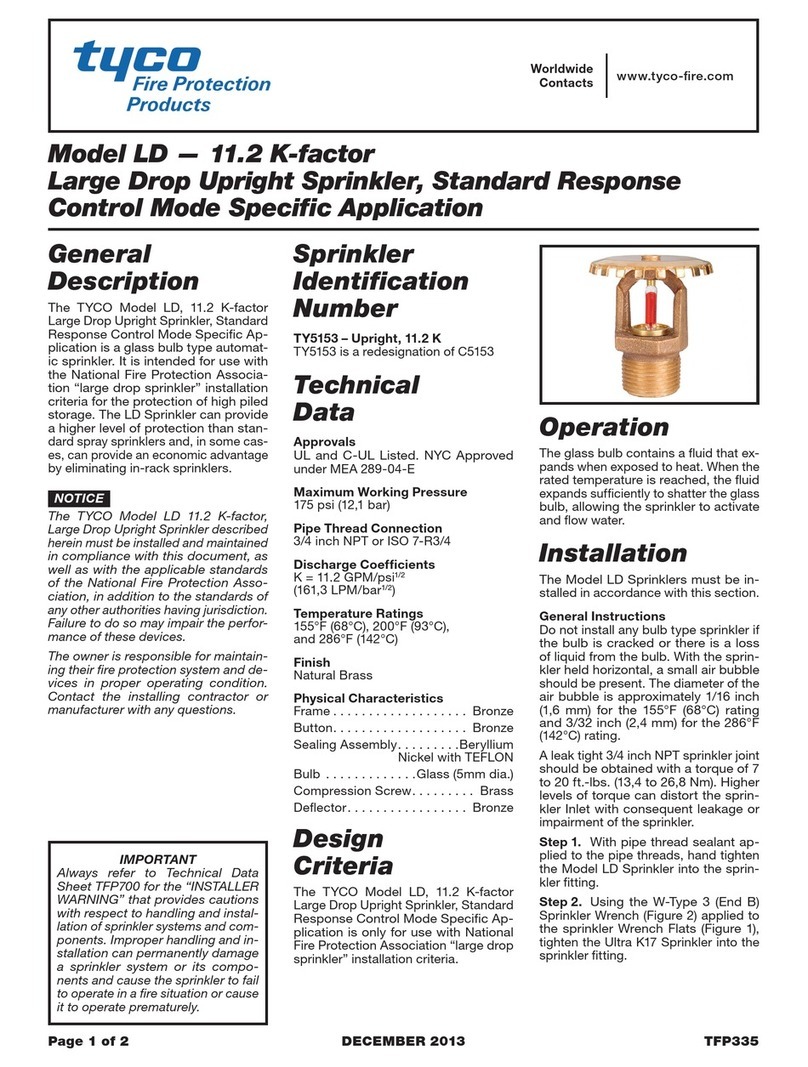

General

Description

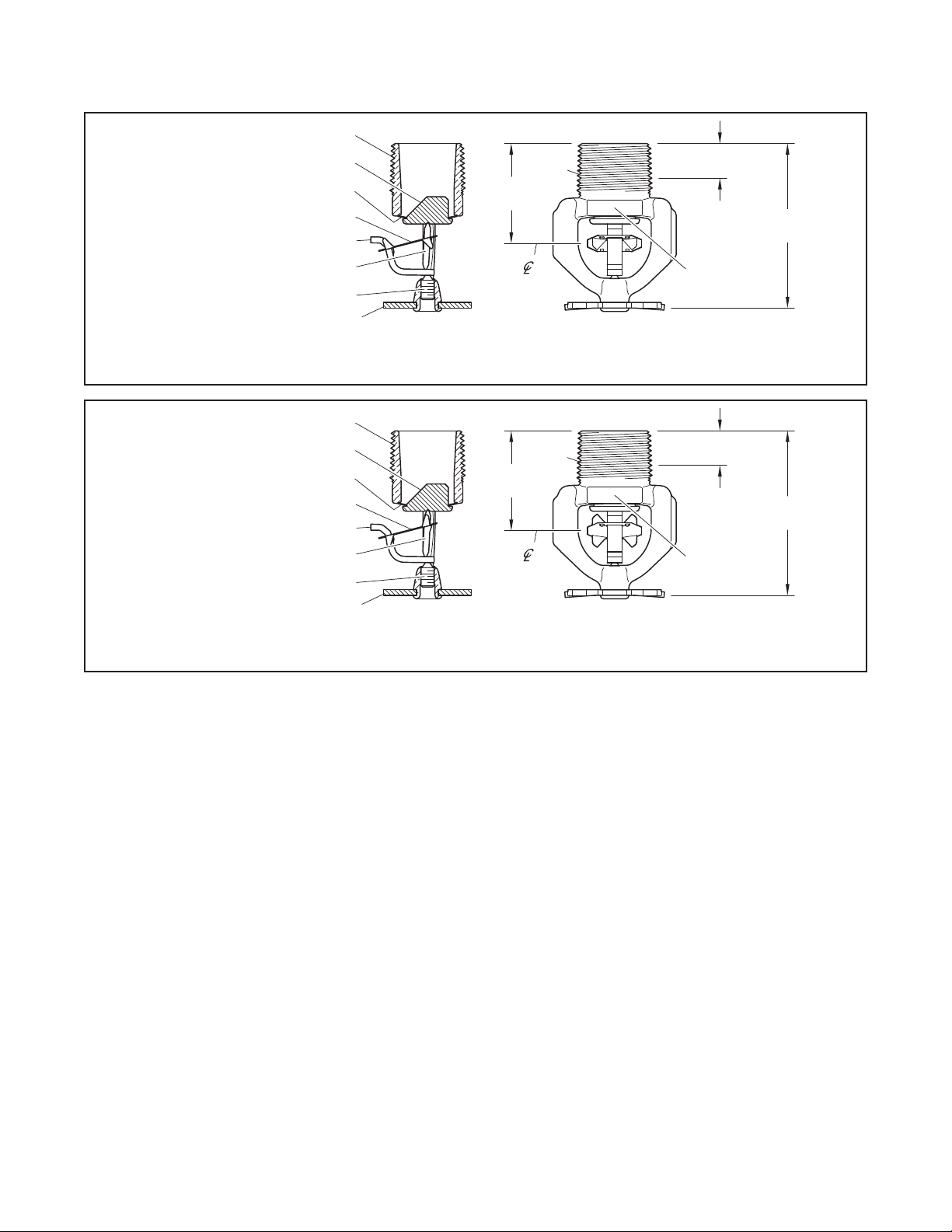

TYCO Model ESFR-17 Pendent Sprin-

klers are Early Suppression, Fast

Response (ESFR) sprinklers having a

nominal K-factor of 16.8 (Ref. Figures

1 and 2). They are suppression mode

sprinklers that are especially advanta-

geous as a means of eliminating in-rack

sprinklers when protecting high-piled

storage.

Model ESFR-17 Pendent Sprinklers are

primarily used for ceiling-only sprinkler

protection of (but not limited to) the fol-

lowing storage applications:

• most encapsulated or non-encap-

sulated common materials including

cartoned, unexpanded plastics

• cartoned, expanded plastics

• uncartoned, unexpanded plastics

• uncartoned, expanded plastics

• some storage arrangements of

rubber tires, roll paper, and aerosols

For more specific criteria, refer to Table

1 in this technical data sheet as well as

the applicable design standard.

The Model ESFR-17 Pendent Sprin-

klers provide the system designer

with hydraulic and sprinkler place-

ment options not presently available

to traditional ESFR Sprinklers having

a nominal K-factor of 14.0. In particu-

lar, Model ESFR-17 Pendent Sprinklers

are designed to operate at substan-

tially lower-end head pressures, as

compared to ESFR Sprinklers having

a nominal K-factor of 14.0. This feature

offers flexibility when sizing system

piping, as well as possibly reducing or

eliminating the need for a system fire

pump.

Applications for the ESFR-17 Pendent

Sprinklers are expanding beyond cur-

rently recognized installation stan-

dards. For information on research fire

tests (with flammable liquids and aero-

sols, for example) that may be accept-

able to an authority having jurisdiction,

contact Tyco Fire Protection Products

(TFPP) Technical Services.

NOTICE

The Model ESFR-17 Pendent Sprinklers

described herein must be installed and

maintained in compliance with this doc-

ument, as well as with the applicable

standards of the National Fire Protec-

tion Association (NFPA), in addition to

the standards of any authorities having

jurisdiction (e.g., FM Global). Failure to

do so may impair the performance of

these devices.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. Contact the installing contrac-

tor or product manufacturer with any

questions.

In all cases, the appropriate NFPA or

FM Global installation standard, or

other applicable standard, must be ref-

erenced to ensure applicability and to

obtain complete installation guidelines.

The general guidelines in this technical

data sheet are not intended to provide

complete installation criteria.

Sprinkler

Identification

Number (SIN)

TY7223