SAFETY RULES

During the installation and the use of the automation, pay

attention to the following safety rules:

Distance security!

Mechanisms moving!

Do not install automation in an environment saturated with

explosive mixtures!

Electric Shock!

Use gloves!

Use welding glasses!

Maintain ear protection!

MAINTENANCE

All repairs must be carried out by ualified people.

Before each intervention remove power through the switch

and lock in that position

The e uipment must be maintained so as to preserve the

conditions that ensure safe and efficient operation

Always use original spare parts

Do not make interventions that modify the machine.

The modified e uipment re uires new CE mark

The settings of the operator must be performed by

ualified personnel, in accordance with the rules of reference.

During these operations provide the presence of two operators

for safety.

DEMOLITION

You have to operate the elimination of the materials in

conformity with the regulations in force. All materials must be

divided by type (copper, aluminium, plastic, electrical parts, etc)

DISMANTLING

In order to move away the automation, follow these

instructions:

1 - cut off the power supply and disconnect the electrical

installation;

2 - dismantle the control console and all the other components

of the installation.

If you have noticed that some components have been damaged,

you have to replace them.

CONFORMITY DECLARATION:

It’s in accordance with Machine Directive 39/89/CE and following

modify.

It’s in accordance with the following directive CE:

Electromagnetic compatibility Directive 89/336/CEE and

following modify.

Low tension Directive 73/23/CEE and following modify.

Have been applied the following harmonized norms:

EN292/1/2, EN 294, EN60335-1, UNI EN 12453, and what

applicable of the EN12445-2000.

USE OF THE AUTOMATION

The gearmotor GR300-400-600 was designed and built for the

opening of gates with max of 5 m leaf or weight max. 300kg.

The GR Srl assumes no responsibility for a purpose other than

that provided by gearmotor GR300-400-600. Since automation

can be put into motion in view by button or remotely by remote

control, it is essential to check fre uently the perfect efficiency

of all safety devices. It is advisable to check periodically (every

six months) the regulation of electronic friction of which must be

e uipped the electronic control board.

PRELIMINARY CHECKS

1 - Read carefully the instructions enclosed in this manual.

2 - Make sure that the gate has a rather solid structure and that

there is no friction points in its movement.

3 - Make sure that the leaf is suitably balanced, even after the

installation of the gear motor.

4 - Check that the electrical installation is in accordance with the

characteristic re uired by the gear motor.

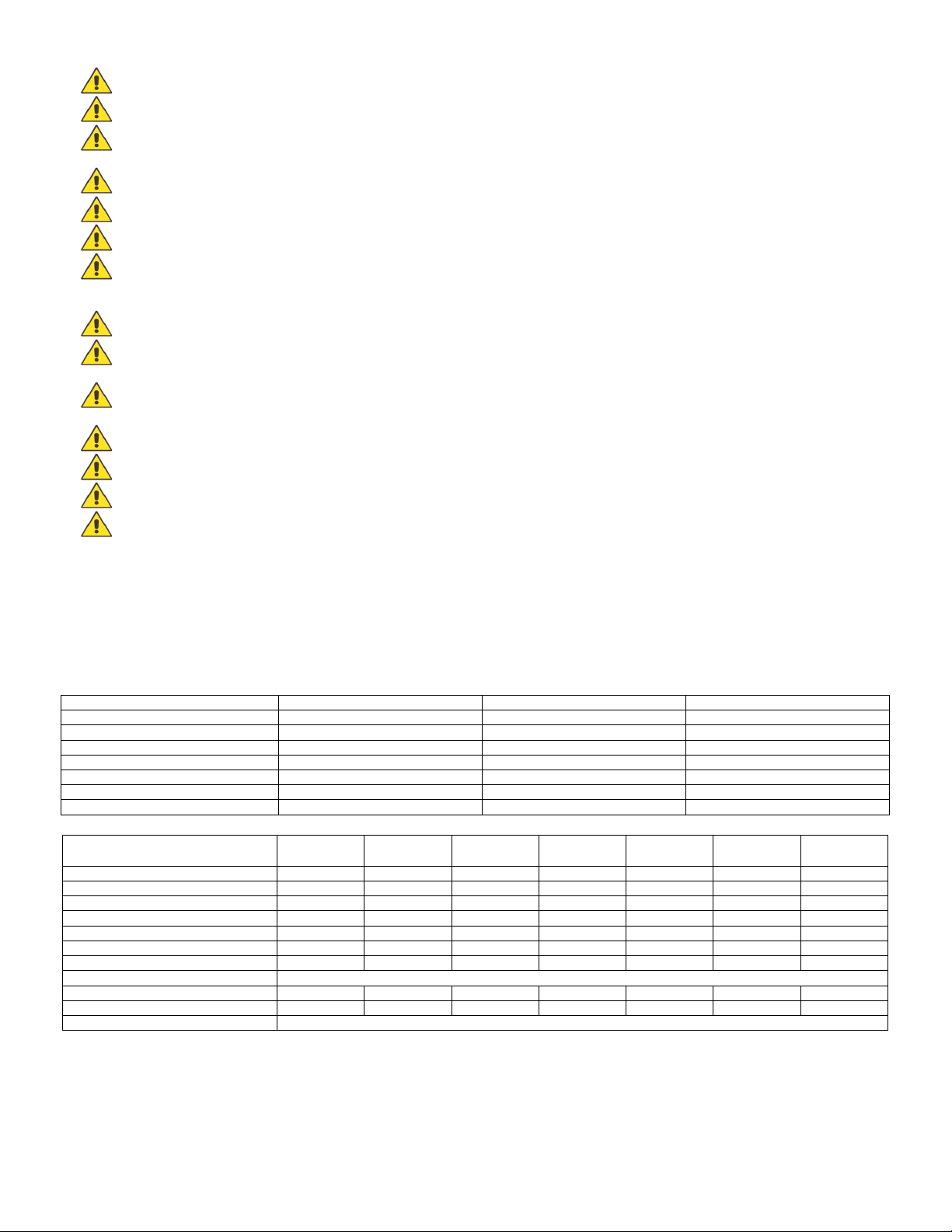

TECHINICAL DATA

GR300 GR400 GR600

Maximum length of the gate 3,0m 4,0m 5,0m

Stroke 30cm 40cm 60cm

Opening time 1400rpm 17sec 22sec 33sec

Opening time 900rpm 25sec 33sec 50sec

Opening time 900rpm REV 17sec 22sec 33sec

Opening time 12-24vrpm 16sec 21sec 31sec

Opening time 2800rpm 8,5sec 11sec 16sec

A1V

220V

A2

220V

A1L

220V

A1

REV

A1

110V

A1

12V

A1

24V

Maximum weight of the gate 300Kg 250Kg 300Kg 300Kg 250Kg 250Kg 250Kg

Power supply 220V 220V 220V 220V 110V 12Vdc 24Vdc

Power 350W 180W 350W 350W 350W 70W 70W

Capacitor 8,0µF 8,0µF 8,0µF 8,0µF 25,0µF – –

Absorption 1,5A 0,9A 1,5A 1,5A 4,6A 0,5–7,5 0,5–5,5

RPM 1400 1400 900 900 1400 1650 1650

Max. Thrust 2200 N 1600 N 2200 N 2200 N 1250 N 1500 N 1500 N

Operating temperature -25°C +60°C

Thermal protection 150°C 150°C 150°C 150°C 150°C – –

Use fre uency 35% 35% 35% 35% 25% 90% 90%

Lubrication GREASE