Table of Contents

INTRODUCTION............................................... 2

Machine Description ...................................... 2

Contact Info.................................................... 2

Manual Accuracy ........................................... 2

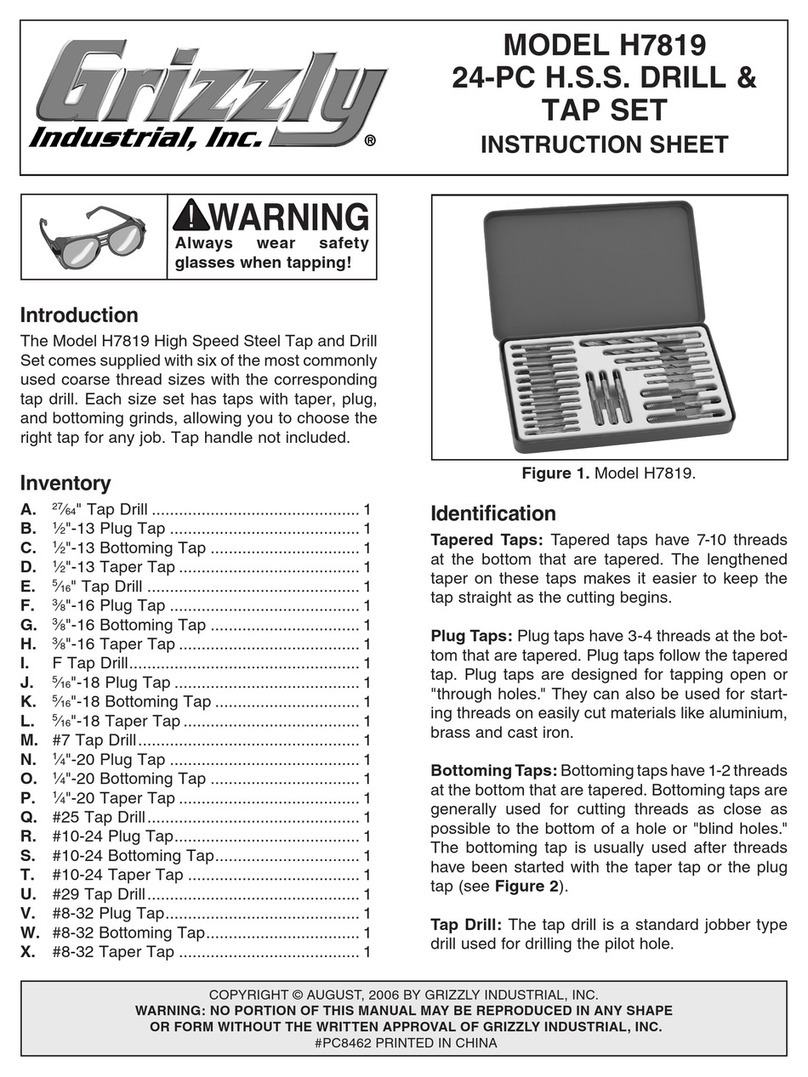

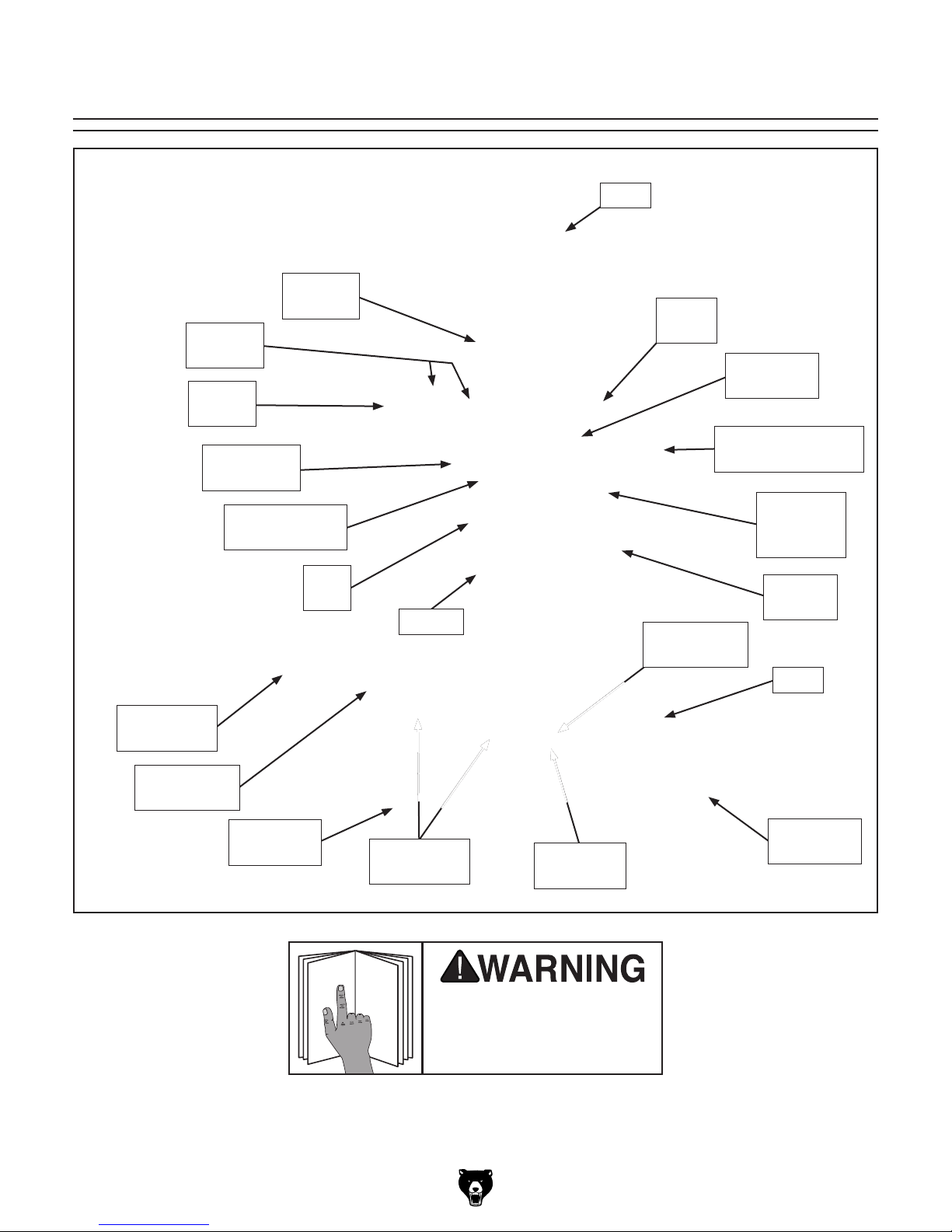

Identification ................................................... 3

Basic Controls ................................................ 4

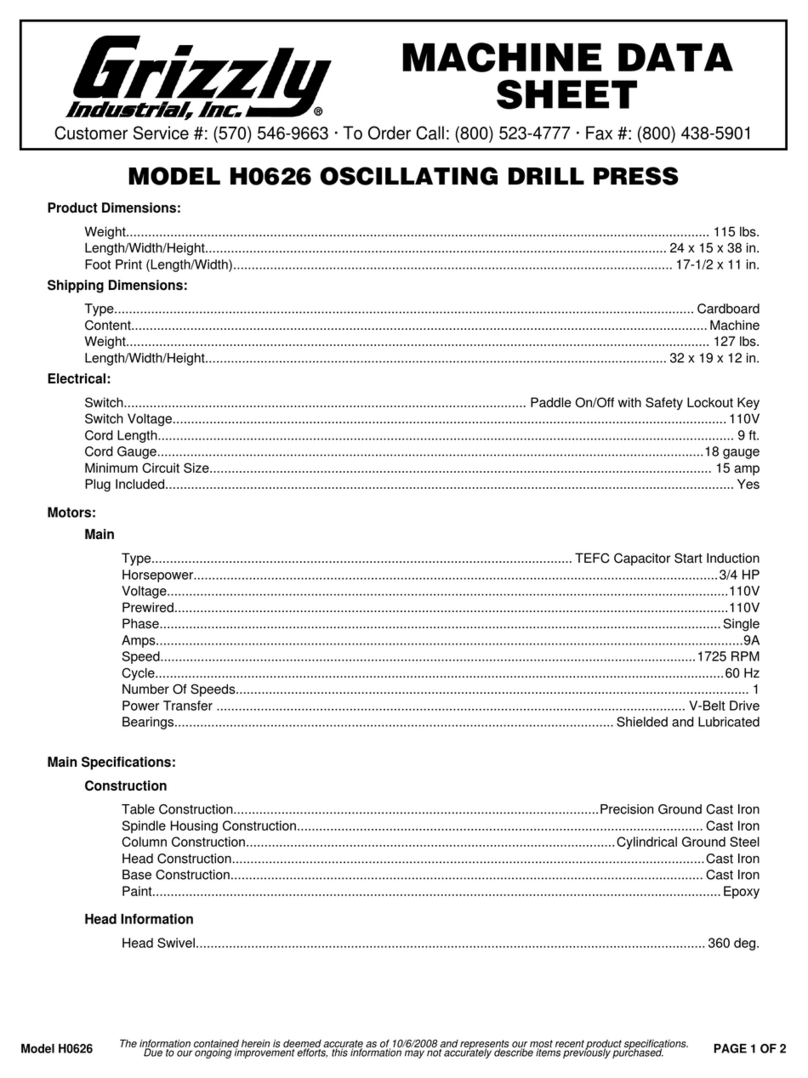

Machine Data Sheet ...................................... 5

SECTION 1: SAFETY....................................... 7

Safety Instructions for Machinery .................. 7

Additional Safety for Mill/Drills ....................... 9

SECTION 2: POWER SUPPLY ...................... 10

Availability .................................................................10

Full-Load Current Rating ...........................................10

Circuit Requirements for 220V ..................................10

Grounding Instructions ..............................................11

Extension Cords ........................................................11

SECTION 3: SETUP ....................................... 12

Unpacking .................................................... 12

Needed for Setup ......................................... 12

Inventory ...................................................... 12

Cleanup ........................................................ 13

Site Considerations ...................................... 14

Lifting & Placing ........................................... 15

Bench Mounting ........................................... 15

Assembly ..................................................... 16

Joining Drill Chuck & Arbor .......................... 16

Lubricating Mill/Drill ...................................... 17

Test Run ...................................................... 17

Spindle Bearing Break-In ............................. 19

Inspections & Adjustments .......................... 19

SECTION 4: OPERATIONS ........................... 20

Operation Overview ..................................... 20

Downfeed Controls ...................................... 21

Identification ..............................................................21

Using Coarse Downfeed ...........................................21

Using Fine Downfeed ................................................21

Depth Stop ................................................... 21

Headstock Movement .................................. 22

Raising/Lowering Headstock .....................................22

Tilting Headstock .......................................................22

Table Travel ................................................. 23

Graduated Dials ........................................................23

X-Axis Handwheel .....................................................23

Y-Axis Handwheel .....................................................23

X-Axis Power Feed ...................................................24

Installing/Removing Tooling ......................... 24

Installing Tooling .......................................................25

Removing Tooling .....................................................25

Spindle Speed.............................................. 26

Determining Spindle Speed ......................................26

Setting Spindle Speed ...............................................26

Tapping Mode .............................................. 27

SECTION 5: ACCESSORIES ......................... 28

SECTION 6: MAINTENANCE......................... 30

Schedule ...................................................... 30

Cleaning and Protecting .............................. 30

Lubrication ................................................... 30

Headstock .................................................................31

Ball Oilers ..................................................................32

Table & Column Ways ..............................................32

Quill Outside Surface ................................................33

Table Leadscrews .....................................................33

Column Leadscrew, Nut, & Pinion Gear ...................34

Quill Rack & Pinion ...................................................34

SECTION 7: SERVICE ................................... 35

Troubleshooting ........................................... 35

Adjusting Gibs .............................................. 37

Adjusting Leadscrew Backlash .................... 37

Tightening Return Spring Tension ............... 38

SECTION 8: WIRING...................................... 39

Wiring Safety Instructions ............................ 39

Electrical Box & Control Panel Wiring ......... 40

Motor & Tapping Switches Wiring ............... 42

SECTION 9: PARTS....................................... 43

Headstock .................................................... 43

Table & Column ........................................... 46

Electrical ...................................................... 48

Accessories .................................................. 49

Labels & Cosmetics ..................................... 50

WARRANTY & RETURNS ............................. 53