Table of Contents

INTRODUCTION ............................................................................................................................... 2

Foreword .................................................................................................................................... 2

Contact Info ................................................................................................................................ 2

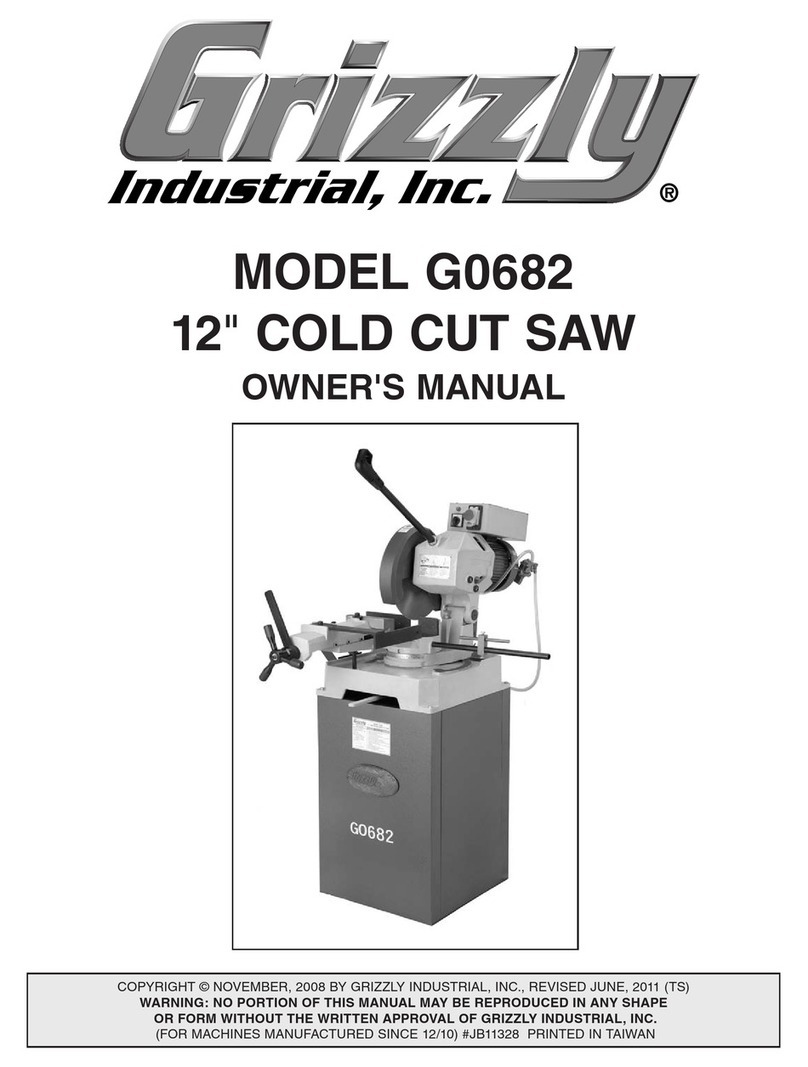

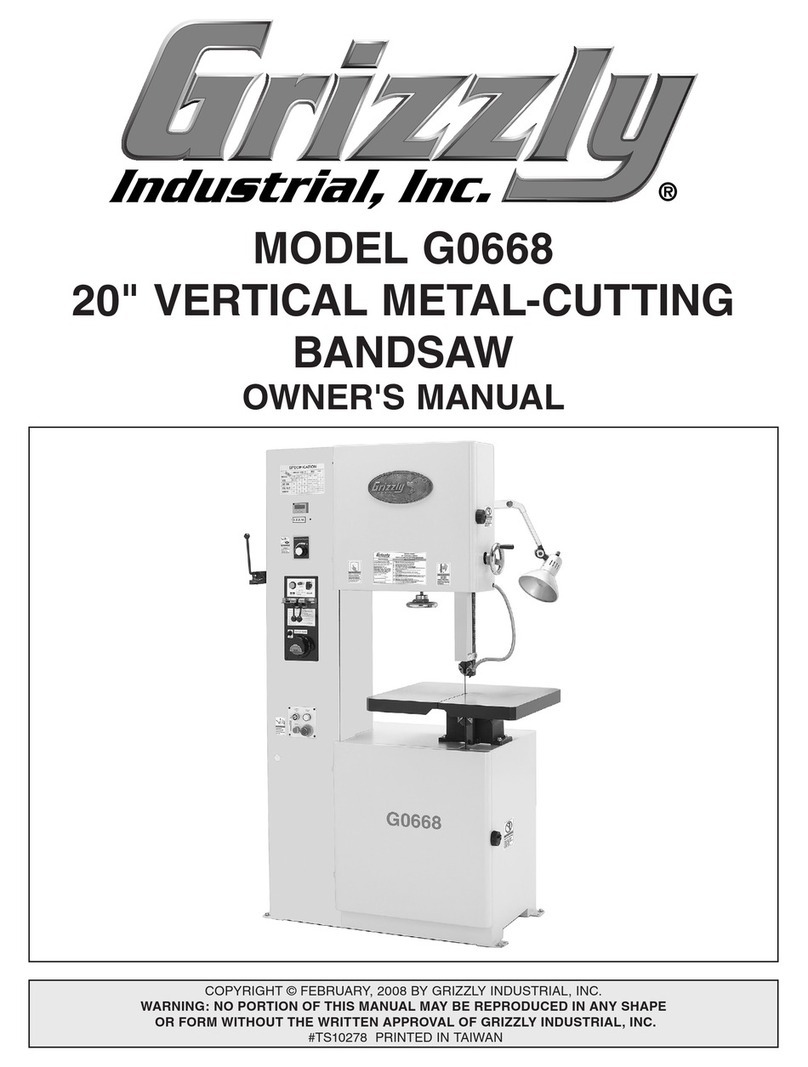

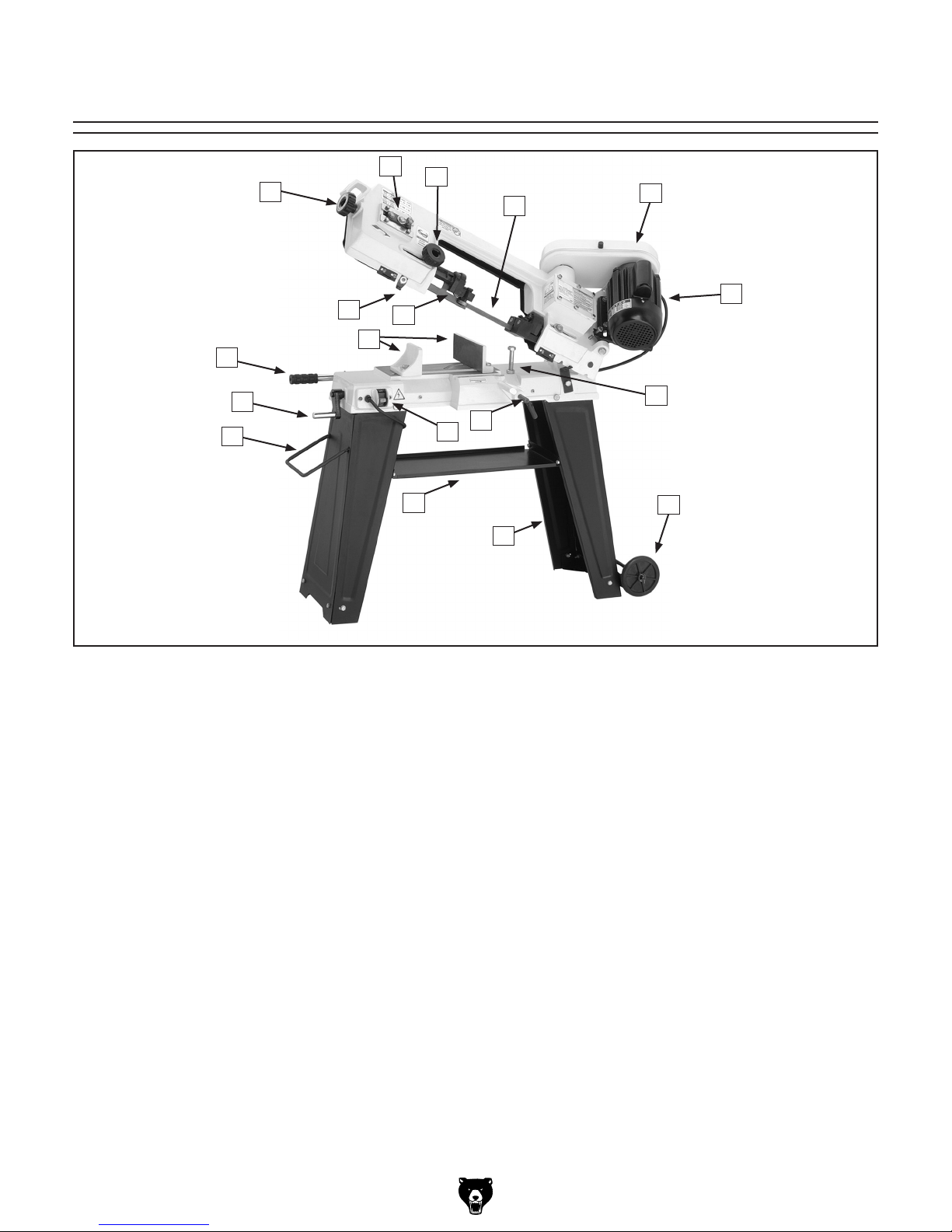

Identification ............................................................................................................................... 5

SECTION 1: SAFETY ....................................................................................................................... 6

Additional Safety Instructions for Metal Cutting Bandsaws ....................................................... 8

SECTION 2: CIRCUIT REQUIREMENTS ........................................................................................ 9

110V Operation .......................................................................................................................... 9

SECTION 3: SET UP ...................................................................................................................... 10

Set Up Safety ........................................................................................................................... 10

Items Needed for Set Up ......................................................................................................... 10

Unpacking ................................................................................................................................ 10

Inventory ................................................................................................................................... 11

Hardware Recognition Chart .................................................................................................... 12

Clean Up .................................................................................................................................. 13

Site Considerations .................................................................................................................. 13

Stand Assembly ....................................................................................................................... 14

Installing Pulleys ...................................................................................................................... 15

Installing V-Belt ........................................................................................................................ 16

Installing Work Stop ................................................................................................................. 17

Vertical Assembly ..................................................................................................................... 17

Test Run ................................................................................................................................... 19

Recommended Adjustments .................................................................................................... 19

SECTION 4: OPERATIONS ........................................................................................................... 20

Operation Safety ...................................................................................................................... 20

Vise .......................................................................................................................................... 20

Blade Speed ............................................................................................................................. 21

Blade Selection ........................................................................................................................ 22

Blade Guides ............................................................................................................................ 23

Feed Rate ................................................................................................................................ 23

Operation Tips .......................................................................................................................... 24

SECTION 5: ACCESSORIES ......................................................................................................... 25

SECTION 6: MAINTENANCE ........................................................................................................ 27

Schedule .................................................................................................................................. 27

Cleaning ................................................................................................................................... 27

Lubrication ................................................................................................................................ 27

SECTION 7: SERVICE ................................................................................................................... 28

Troubleshooting ........................................................................................................................ 28

Blade Change .......................................................................................................................... 30

Blade Tracking ......................................................................................................................... 31

Blade Tension .......................................................................................................................... 32

Squaring the Blade ................................................................................................................... 32

Blade Guide Bearings .............................................................................................................. 33

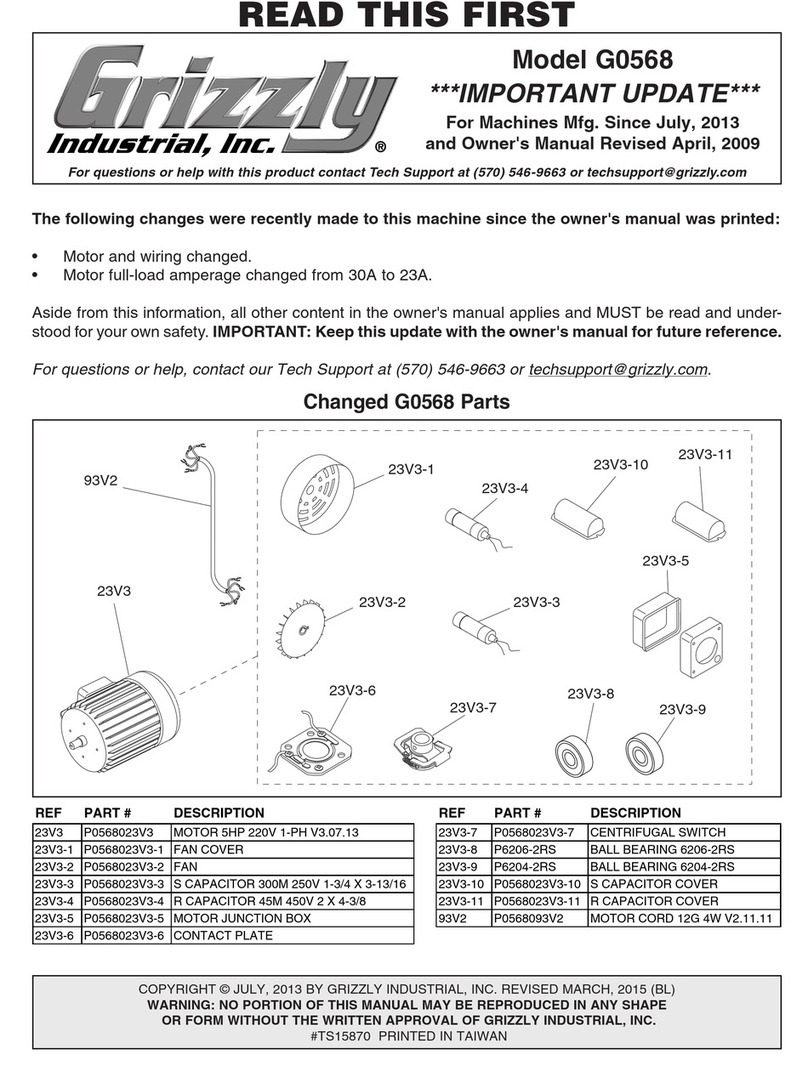

Electrical Components ............................................................................................................. 34

Wiring Diagram ........................................................................................................................ 34

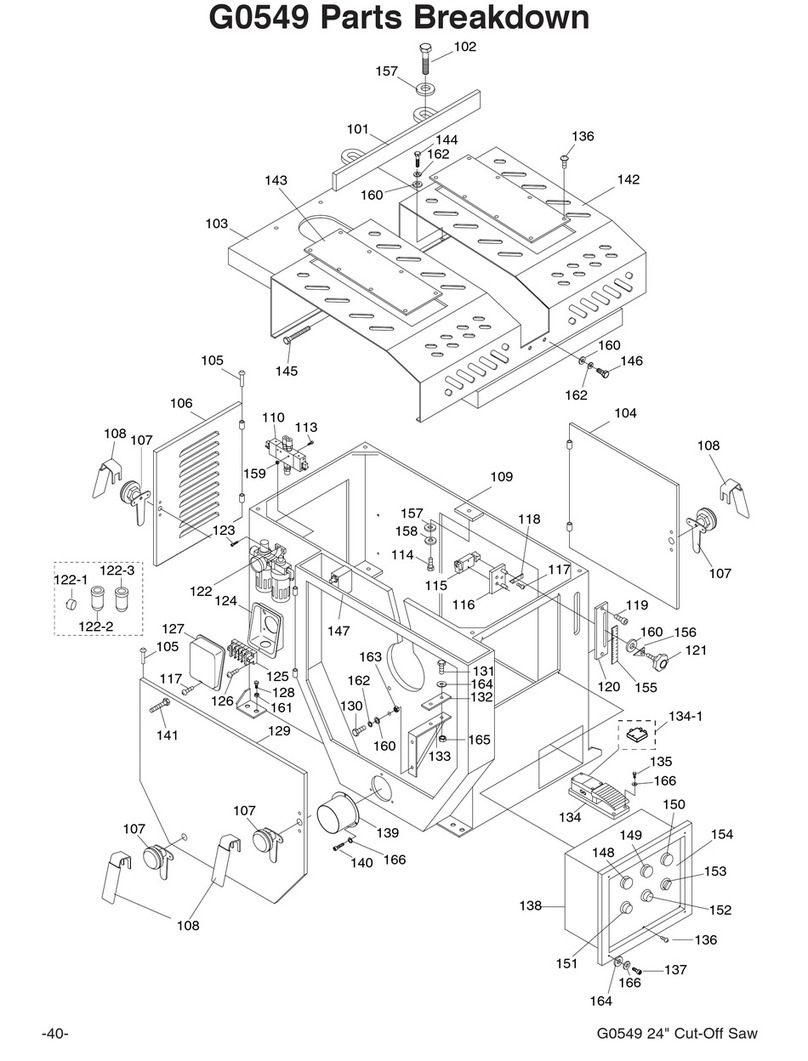

Parts Breakdown ...................................................................................................................... 35

Parts List .................................................................................................................................. 36

Parts List .................................................................................................................................. 37

WARRANTY AND RETURNS ........................................................................................................ 38